This article is devoted to the creation of an axial neodymium magnet generator with metal-free stators. Windmills of this design have become especially popular due to the growing availability of neodymium magnets.

Materials and tools used to build the windmill of this model:

1) the hub of the car with brake discs.

2) a drill with a metal brush.

3) 20 neodymium magnets measuring 25 by 8 mm.

4) epoxy resin

5) mastic

6) PVC pipe 160 mm diameter

7) hand winch

8) metal pipe 6 meters long

Consider the main stages of building a windmill.

The hub of the car with a brake disc was taken as the basis of the generator. Since the main part of factory production, this will serve as a guarantor of quality and reliability. The hub was completely disassembled, the bearings inside it were checked for integrity and lubricated. Since the hub was removed from the old car, the rust had to be cleaned with a brush, which the author planted on the drill.

Below is a photograph of the hub.

Then the author proceeded to install magnets on the rotor discs. 20 magnets were used. Moreover, it is important to note that for a single-phase generator the number of magnets involved is equal to the number of poles; for a two-phase generator, the ratio will be three to two or four poles to three coils. Magnets should be mounted on alternating poles. To maintain accuracy, you need to make a layout template on paper, or draw lines of sectors directly on the disk itself.

You should also mark the magnets at the poles with a marker. You can determine the poles by moving the magnets in turn to one side of the checking magnet, if attracted - plus, repelled - minus, the main thing is that the poles alternate when installed on a disk. This is necessary because the magnets on the disks should be attracted to each other, and this will only happen if the magnets opposite each other will be of different polarity.

The magnets were glued to the discs with epoxy. To prevent the resin from spreading beyond the boundaries of the disk, the author made borders along the edges with mastic, the same can be done with adhesive tape, simply by wrapping the wheel in a circle.

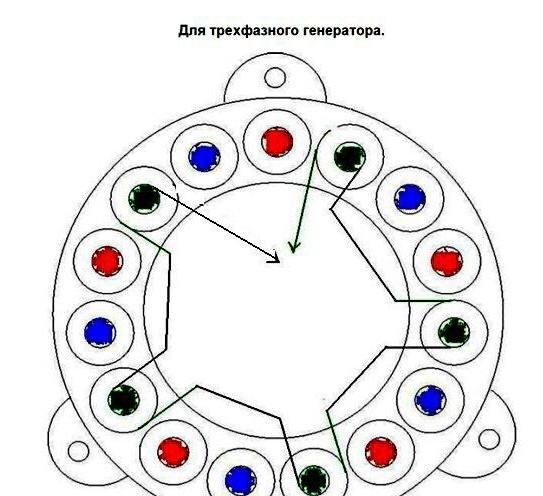

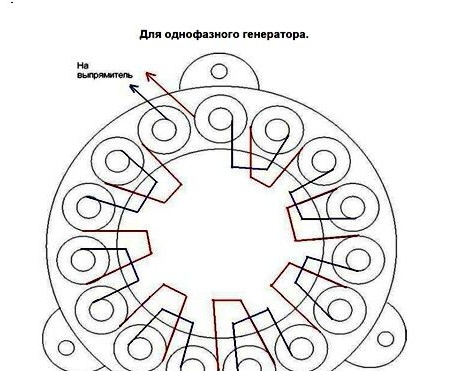

Consider the main differences in the design of single-phase and three-phase generators.

A single-phase generator will produce vibration under loads, which will affect the power of the generator itself.The three-phase design is devoid of such a drawback due to which, the power is constant at any time. This is because the phases compensate for the loss of current in each other. According to the author’s conservative estimates, the three-phase design is as much as 50 percent superior to the single-phase design. In addition, due to the lack of vibration, the mast will not swing additionally, therefore there will be no additional noise during operation of the rotor.

When calculating the charge of the 12th battery, which will start at 100-150 rpm, the author made 1000-1200 turns in coils. When winding coils, the author used the maximum allowable thickness of the wire to avoid resistance.

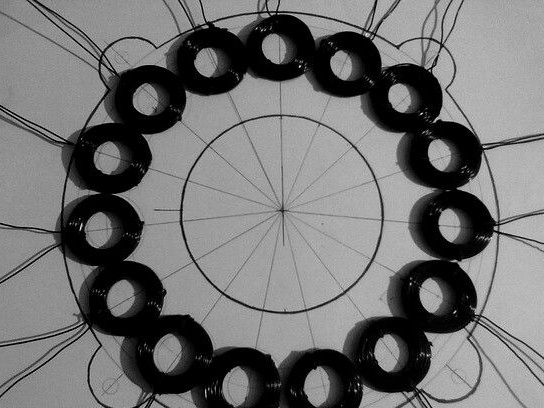

To wind the wire around the reels, the author built a home-made machine, photos of which are presented below.

It is better to use coils of ellipsoidal shape, which will allow a higher density of magnetic fields to cross them. The inner hole of the coil should be made according to the diameter of the magnet or larger. If you make them smaller, then the frontal parts practically do not participate in the generation of electricity, but serve as conductors.

The thickness of the stator itself should be equal to the thickness of the magnets that are involved in the installation.

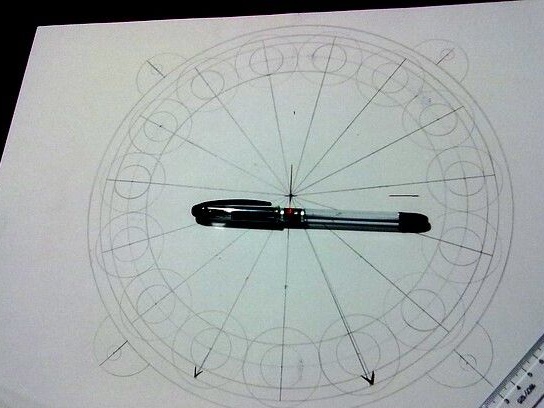

The form for the stator can be made of plywood, although the author decided this question differently. A template was drawn on paper, and then the sides were made using mastic. Also, fiberglass was used for strength. In order for the epoxy not to stick to the mold, it must be lubricated with wax or petroleum jelly, or you can use tape, a film that can later be torn off the finished mold.

Before pouring the coils, it is necessary to precisely fix them, and their ends out of the mold, so that then connect the wires with a star or a triangle.

After the main part of the generator was assembled, the author measured tested his work. With manual rotation, the generator generates a voltage of 40 volts and a current strength of 10 amperes.

Then the author made a mast for a generator 6 meters high. In the future, it is planned to increase the height of the mast by using a thicker pipe at least twice. That the mast was motionless the base was flooded with concrete. A metal mount was made to lower and raise the mast. This is necessary in order to have access to the screw on the ground, since it is not particularly convenient to carry out repair work at heights.

A manual winch is used to raise the mast.

The screw for the generator itself was made of PVC pipe with a diameter of 160 mm.

After installing and testing the generator under standard conditions, the author made the following observations: the generator power reaches 300 watts with a wind of 8 meters per second. Subsequently, he increased the power of the generator due to the metal cores installed in the coils. The screw starts at two meters per second.

Further, the author began to improve the design in order to increase the power of the generator. Magnetic cores from plates were drawn, which were subsequently installed in the structure. Because of their installation, a sticking effect appeared, but not very strong. The screw starts at a wind speed of about two meters per second.

Thus, the installation of metal cores increased the generator power to 500 watts with a wind of 8 meters per second.

To protect against strong winds, a classic folding tail propeller circuit was used.

On average, a generator is capable of generating up to 150 watts of energy per hour, which is used to charge the batteries.