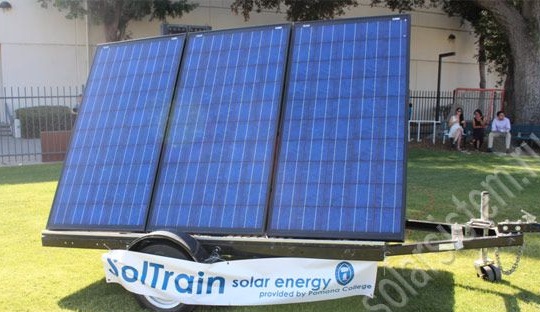

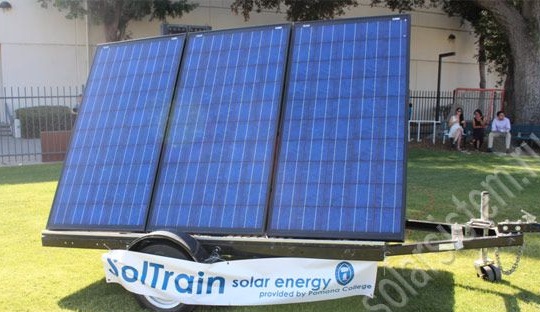

In past articles, we have already seen examples of mobile power plants. By their purpose, application and essence of the work, they are not very different, their main difference lies in one very important parameter - power. In this article, the author found a solution to the problem of combining the power of a solar-powered power plant and its mobility.

Materials used to create a mobile solar power station:

1) automobile trailer

2) solar panels 190 W (24V, 8A) in the amount of 3 pieces

3) FLEXmax brand charge controller

4) inverter 12 \ 220 V with a power of 1000 W

5) batteries 12 V, 120 A \ h in the amount of 6 pieces

6) profile pipe

7) wires with a cross section of 16 mm

The main points of creation and design features of this model of a solar power plant.

Since the capacity of the planned power plant will be about 1 kW, its weight will also be not small. Therefore, to simplify the movement of the structure, a wheelbase is required. The author decided to mount it on a car trailer, as it ideally fits the characteristics of his power plant. The dimensions of the trailer used, as the basis of the frame of the power plant, can be different and completely depend on your needs for the power of the power plant and financial capabilities. There are examples of creating solar power plants even on the basis of refrigerators:

When choosing a trailer for a power plant, the author considered such a length that it was possible to fix the solar panels on the same plane, although there are other methods of fastening in which the solar panels unfold like a book.

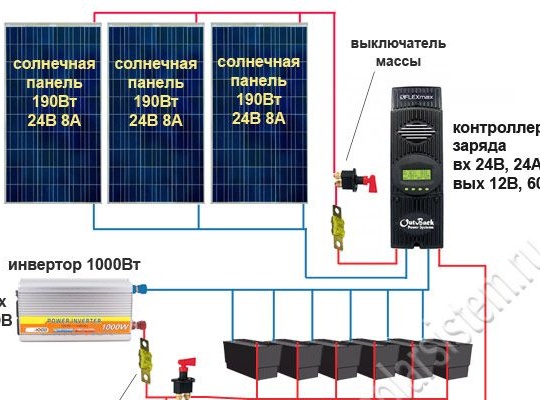

Below is a diagram of a solar power plant:

You may have noticed that solar panels and batteries are designed for different voltages, but this is allowed when using the selected model of the charge controller.

The circuit breakers are used, which are necessary to ensure the safety of repair and maintenance work. Fuses were selected depending on the current strength of the solar panels and the power consumption from the batteries. In this model, the current strength of the solar panels is 24 A, so a fuse rated at 25 A was installed for greater reliability. A fuse was also installed between the battery and the inverter. In this case, the fuse is selected based on the maximum inverter current. Since the inverter power is 1 kW, and the consumed voltage is 12 V, the maximum current consumption can be 83.4 A, since the calculation is performed according to the formula current = power \ voltage. Therefore, according to the calculations, a 90 A fuse was selected

Before starting the installation of the system, it is necessary to prepare the trailer. From a profile pipe, the author made a frame on which solar panels will be mounted. At this stage, the author advises considering the possibility of creating a frame so that it can be folded during transportation to reduce height and windage.

Then the author proceeded to install batteries under the solar panels. The batteries were installed in one row and connected in parallel. A mandatory criterion in this case is the rigid fixation of the batteries, so that they remain stationary during trips, as otherwise they can lead to wire breakage, break themselves or damage another electronics.

Wires also need to be selected based on the calculation of the operating current of the system, preferably with a margin. When using this inverter for 1 kW, a current of about 83 A will pass through the wires, so at least 16 mm of the wire cross section was chosen to connect the batteries.

For the installation of electronics, the author made a stand made of plywood, which will be located under the solar panels, so they will be relatively protected from rain. Below are photos of used electronics.

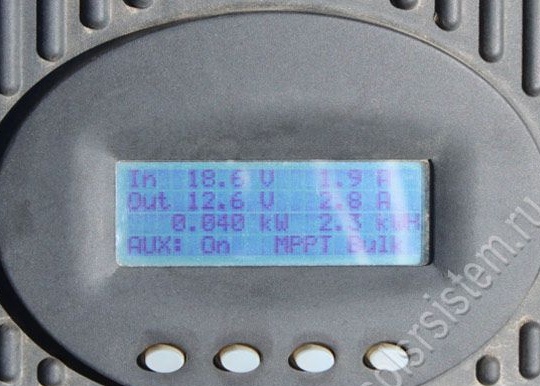

Solar Power Station Control Unit:

Solar Charge Controller:

Inverter:

Since a solar-powered power plant is a source of increased danger due to the high current flowing in its circuits, the author made sure that there was no open access to the electric circuit. For starters, the easiest way was chosen with a plastic mesh that covers dangerous areas, but in the future the author plans to make a ventilated dielectric box made of plastic or plywood.

In a field test, this model the solar power station fully charges the batteries from scratch in 15 hours, in particular thanks to the installed MRPT controller, which converts the excess voltage into current to charge the batteries. At a maximum load of 1 kW, the operation of the batteries until full discharge is 6 hours.

These indicators fully meet the needs of the author. However, if such indicators were not enough for you, then before building your own solar-powered power plant, you need to make a complete calculation of the entire structure, and, starting from the requirements, select the necessary equipment of the given capacity.