In the manufacture of portable solar-powered chargers, one problem always arises: a small solar battery cannot generate large currents, which means a rather slow charge on the phone, tablet and other devices. If you use solar panels of large dimensions, then the convenience of mobility of such devices is lost. The author of this product solved the problem in his own way. He decided to make a folding solar panel, which will be easy to carry in a box when folded, and when using it, expand into a wide, fully functional solar panel.

Materials that were needed to make a portable folding solar battery:

1) polycrystalline solar cells 52 by 76 mm in the amount of 6 pcs., With a voltage of 0.5 V and a power of 0.32 watts.

2) EVA film, which is used for the production of triplex glass

3) polycarbonate with a thickness of 0.2 mm.

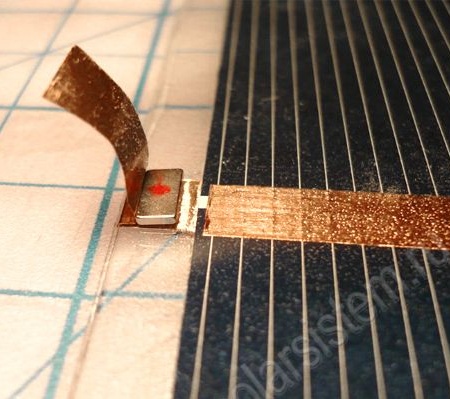

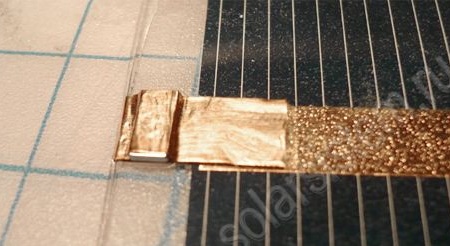

4) a copper tape with a thickness of 0.07 - 0.12 mm with a conductive adhesive layer.

The author notes that it is possible to purchase separately copper tape and separately glue, the main thing is that the glue is conductive.

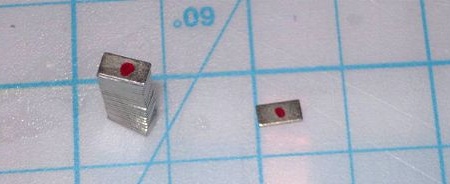

5) neodymium magnets measuring 5 by 2.5 by 1 mm, based on two magnets per solar cell.

6) laminator

7) parchment paper

8) marker

9) super glue

Let us consider in more detail the main stages of creation and the design elements of a folding solar battery.

After all the necessary materials and tools were prepared for work, the author proceeded to assembling the solar panel.

To begin with, a tape was cut into pieces 70 mm long. Each such tape was glued to the contacts from the front and back of the element, so that the remaining 20 mm of the tape went in different directions of the element.

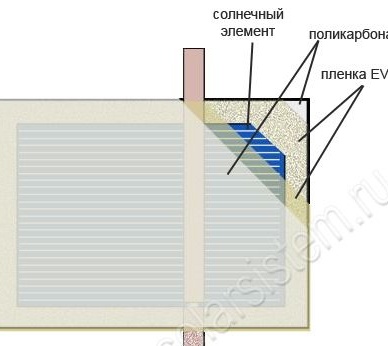

Then fragments of size 65 by 90 mm were cut from sheets of EVA film and polycarbonate. In this case, we had to make 2 such fragments for each element. Polycarbonate is very important for giving strength to the solar cell, since without such protection there is a great chance to break the elements during repeated deployment and folding.

Moreover, the EVA film itself is a connecting link between the solar cell and polycarbonate, since when it is heated, it adheres to the surface of each of the materials.

Next, we begin preparing for the lamination of solar cells.To do this, the protective coating is removed from the polycarbonate and the film, and the solar cells themselves are placed in the center between the layers.

Below is a diagram of the arrangement of layers when laminating a solar cell:

After preparation, the author proceeded directly to the lamination of solar cells. In order not to stain the laminator with glue that will protrude from the EVA film, the author placed solar cells between layers of parchment paper. If you do not have a laminator, then lamination can be done using a conventional iron.

After the elements cooled down, the author cut off the excess glue along the edges.

After all the elements were laminated, the author proceeded to install neodymium magnets. But before proceeding with the installation, the author made the marking of the poles of the magnets so that during assembly the magnets are attracted to each other, and not vice versa. The author made marking with a regular marker.

A neodymium magnet was placed on polycarbonate at a distance of 1 mm from the edge, for fixing it was glued with super glue.

Next, a magnet is bent around with a copper tape, and since there is also a layer of glue on the tape, such a fastener will be quite reliable and of high quality.

A similar operation was performed with each solar cell.

After which the author proceeded to test each assembled solar cell for efficiency.

When all the elements were checked, the author began to combine them into one solar battery. Magnets are connected quite simply with the help of installed magnets. As a result, the power of such a solar battery was 2 W, which makes it possible to charge a mobile phone with a current of 0.4 A.

In order not to connect the magnets in one line, the author chose to connect them with a snake to fix with a paper clip.

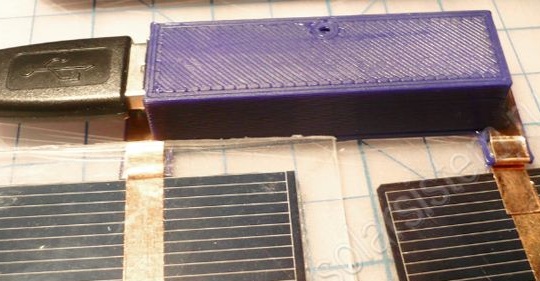

By the next step, the author placed the charge controller in his plastic case, and connected the contacts to the solar battery using magnets and a copper tape.

Thanks to the magnetic mount, the elements are quite convenient to lay out on the hood of the car, or the frame of the bicycle. Due to the good power of the magnets, they securely fasten the elements to a metal surface.

During transportation, this solar panel is disassembled and easily fits in a small box. The author recalls that although the solar cells are reinforced with polycarbonate, they are still quite fragile, so bending the cells in every way is not welcome, but if you cracked one or more cells, they still continue to work.

The most important drawback of this model of a solar battery is the following: copper oxidizes rapidly, which results in poor contact quality, which in turn is displayed on battery power. To preserve the power of the solar battery, it is necessary to constantly strip the contacts, or tin them with tin solder.