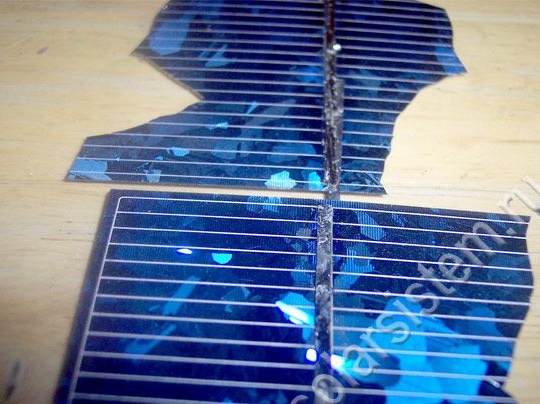

Solar cells are quite thin, usually their thickness varies from 0.2 mm to 0.4 mm, so they are very fragile and easily break. Therefore, situations are not uncommon when, when working with solar cells, a certain amount of broken, broken elements appears, and it also happens that when you receive a package, you notice that many elements are damaged. However, even a broken element continues to work, which means that they can be used to create a solar panel.

Materials needed to create a solar panel from broken solar cells:

1) fragments of solar cells

2) a soldering iron with a capacity of 15-25 watts, as well as the necessary consumables for it

3) multimeter

4) eraser

5) foil tape

Consider the main features of working with broken solar cells and the stages of creating a working panel of them.

Naturally, when assembling a panel of broken solar cells, you need to know and take into account several features.

For example, a broken solar cell will produce the same voltage as stated for whole cells, but the current strength from a broken cell will directly depend on the size of the fragment.

It is also important to know that during a series connection, the voltage will be summed, and the current value will remain unchanged. That is, to obtain the required voltage of 12 V for charging the battery, 24 solar cells must be connected in series, the voltage of each of which is 0.5 V.

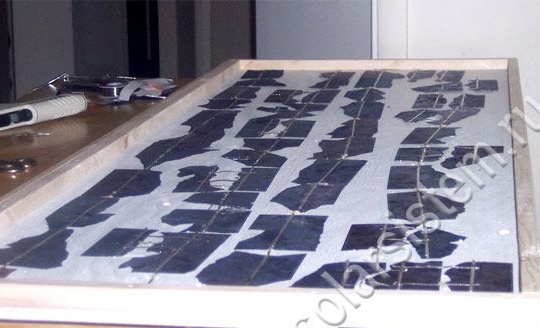

And the magnitude of the current will depend on the smallest fragment in the series circuit of the elements. Thus, if you connect 23 elements in series with an area of 10 cm² and one with an area of 2 cm², then an element with an area of 2 cm² will determine the current strength. That is why, before starting the assembly of the panel, it is necessary to sort all the fragments of solar cells by size.

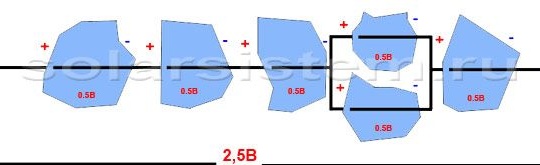

If, after sorting, you notice that you do not have enough large fragments of elements to assemble one line of the circuit, then you can connect two small fragments in parallel, since with a parallel connection, the current strength is added up, and the voltage remains unchanged.

Below is a diagram of such a connection, where two small fragments are used connected in parallel in a series circuit of solar cells:

Having decided on the layout and arrangement of the elements, the author started preparing the elements for soldering.

Basically, mono and polycrystalline elements have a negative pole on the front side and a positive pole on the back side.

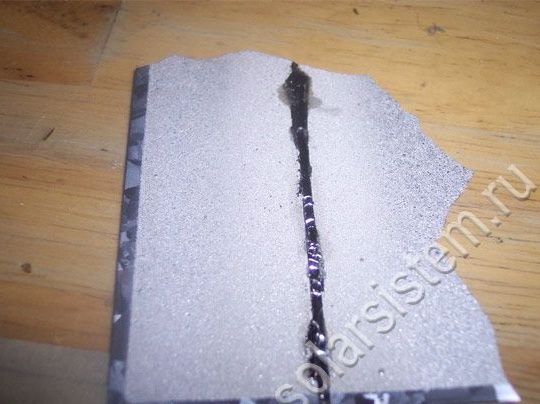

Before soldering the bus to solar cells, it is necessary to strip their contacts. For these purposes, an ordinary eraser is suitable. The contacts must be thoroughly cleaned so that the solder is distributed evenly throughout the contact. At the same time, cleaning must be done carefully so as not to break the fragile fragments of the elements into even smaller parts.

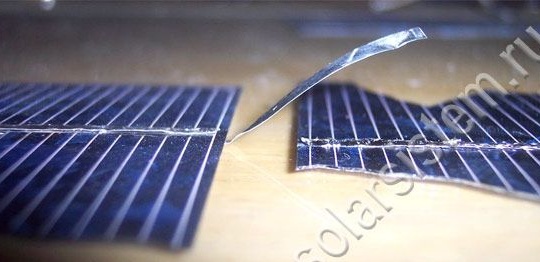

After the contacts were stripped, the author proceeded to tinning the contacts of the front and back sides. When working with a soldering iron, it is also necessary to avoid excessive loads on solar cells.

After that, you can begin to solder the bus to the back of the element. When soldering a foil tire, leave the tire margin in one direction for connection with the subsequent chain element. If the tire has already been soldered on the front side, the margin is shorter, that is, try to calculate the tire length correctly.

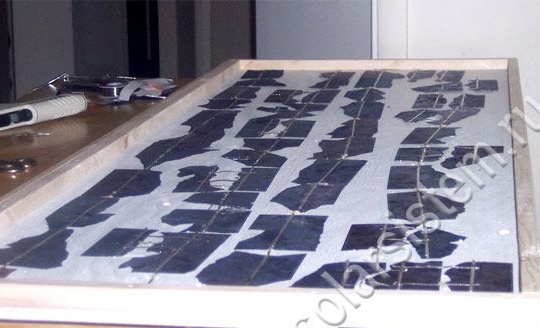

After the bus has been soldered to each element, it remains only to connect all the elements into one serial circuit. The author took the left stock of the tire from the back of the element and soldered it to the front side of the subsequent element. Thus, several series circuits were assembled, which were then interconnected in parallel to increase the output current.

It is clear that a solar panel from the remaining fragments of broken elements will have lower performance than the same panel from whole elements. But basically it will be because of the area occupied by the elements, if you place the fragments as densely as possible, then the efficiency of such a panel will tend to the efficiency of the panel of the same area from whole elements.

Another disadvantage of this panel is the appearance of the design, which leaves much to be desired. But in this way you can even use broken elements, instead of just throwing them in the trash. If the appearance and size of the panel is not important to you, then you can even specifically buy broken elements on eBay to create similar solar panels from them, because broken elements can often cost several times less than whole ones.