The author has long been interested in the idea of using alternative energy. After searching for information about various devices on this topic, the author found for himself model a windmill that is easy to implement and not very costly for money.

Materials used by the author to create a windmill:

1) wires 3 \ 8-16

2)electronic charge controller

3) GM 7127 generator from AutoZone

4) stator upgrade kit - MTM cientific,

5) carbon fiber blades and hub - Picou Builders Supply, Co Inc.,

6) water pipes

7) 38 V DC tape drive motor Ametek

Consider the stages of creating a wind generator.

To begin with, the author has acquired all the necessary components. Pipes and several meters of wires were bought at a hardware store. Through online stores, high-voltage stator coils and transmission were ordered. An electronic controller was purchased to indicate battery charge.

After that, the author began assembling the main design of the wind generator.

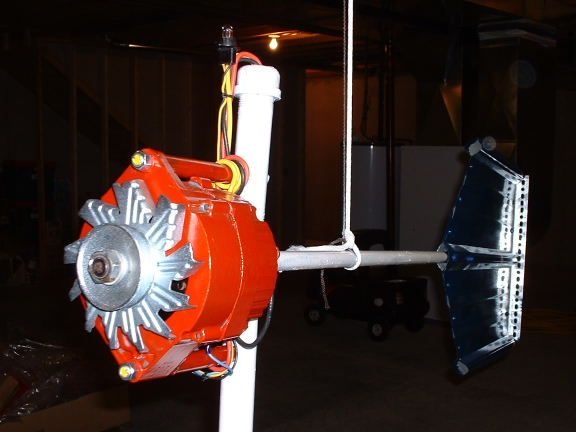

The generator was mounted on a rack, and a small diode was installed on the top of the turbine rack, which was wired to the generator coil. Since this is not a permanent magnet generator, the light bulb allows the coil to self-excite and shows the moment when the generator does not give out a charge, and therefore can be disconnected from the battery.

Then carbon fiber blades were made. After which the author proceeded to paint work. the author himself painted the generator in red, and the hub and fasteners of the blades in white.

After assembly and painting, the author only had to wait for a calm day to install the design of the wind generator.

Before starting the installation, the author decided to remove the blades, to facilitate the installation of the generator on the top of the tower.

Having once again calculated the length of the flagpole, the author discovered an error due to which it would not be possible to install the mechanism perfectly. Therefore, according to new calculations, the author cut 16 "pipes, but it turned out to be a little thicker than necessary. Therefore, armed with files, the author began to eliminate all the calculation flaws manually.

For the convenience of raising the wind turbine and installing it, the author assembled a three-leg lift and, with the help of an assistant and a home-made elevator, the entire structure was lifted to the rack platform, where it was strengthened and balanced.

As you can see in the photo, three cables depart from the generator, which the author will connect to the energy storage system from the wind turbine.

The first tests showed the reliability of the design. With a strong wind of about 35 miles / hour, the generator began to make noise, but the fixtures could withstand. However, during the tests, the main drawback of this generator was revealed, which the author missed. the fact is that the car generator does not start to generate current until the wind reaches 12 miles \ hour

Last night a strong enough wind was blowing, but the turbine was “on top”. At times, a gust of wind reached 35-40 mph. With such a wind, the turbine made noise, but most importantly, it passed the test. Due to the factory limitation, the car generator does not start to generate current until the wind reaches 12 mph, and at zero rpm it does not generate energy and does not show voltage. When the wind is less than 12 mph and low generator speeds, it consumes battery power itself until the current generation starts, which practically spoiled it. Therefore, in order to fix the system and save batteries, the author decided to modernize the generator in such a way as to make an alternating current generator with a permanent magnet out of it.

The stator winding has been rewound. Initially, the stator had 4 turns of wire No. 14, they were replaced by 10 turns of wire No. 18. Laying the last 4 wires in the last layer was a difficult task, the author even tried using the press to make indentations in the stator, but this did not bring results.

Therefore, the author simply carved a pocket deep in the finger for a new magnet.

As a result, the whole stator rewind venture failed, as some winding rings came into contact with the metal core and created a short circuit. Therefore, the author rejected this venture and purchased a DC Ametek tape drive motor with a capacity of 38 V. The author marked the mouthguards and spread them for greater convenience. The purchased rotor with beveled grooves gave a pretty good starting torque, when tested on manual traction the voltmeter showed a little more than 9 V.

In order to attach the generator to the same mount that was used for the old automobile alternator, the author machined a flange.

The new stator is relatively smaller in size than its predecessor, but it starts to work even with the weakest winds. In order to overcome the resistance of the battery and start charging, enough wind power of 7-8 mph. In this case, the installed diode does not allow the generator to switch to motor mode.

And here is a photograph of the system’s battery pack.

In order for the windmill to rotate relative to the wind, the author made a rotary mechanism. The generator is mounted on the right, and the tail is mounted on the curved part of the pipe at the rear.

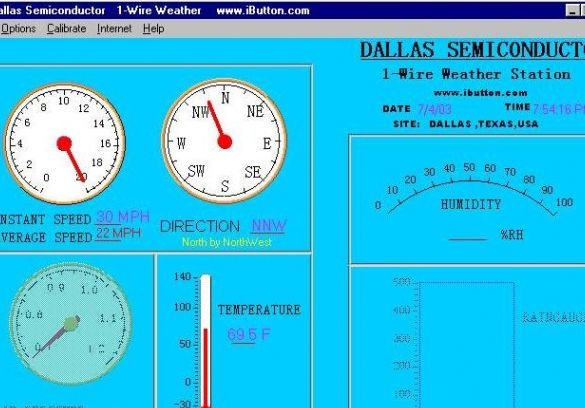

For clarity, the results of testing a new design, the author installed an ammeter and a voltmeter on the instrument board. Thanks to this, it became easier for him to control the readings, and therefore to calculate the received power of the wind generator.

The tape drive motor was connected to a rotation mechanism. Before that, bearings were replaced in the engine itself, and the author also decided to cover it with paint to protect it from corrosion.

As a result, at a wind speed of about 13 mph, the generator is capable of delivering more than 200 watts.