To make useful things with the proper approach is possible from almost any material. The author decided to prove this by creating a solar furnace from mud, clay and straw. At the same time, a decent stove turned out, which looks great on a summer cottage.

The materials used by the author for the manufacture of this design of the solar furnace:

1) clay

2) straw

3) brick

4) cobblestone

5) cement

6) glass

7) aluminum sheet

8) wooden blocks

9) metal pins

10) mirror

11) insulation material

Let us consider in more detail the main stages of creating a solar furnace and the essence of its work.

First of all, the author decided to create the foundation for the future stationary solar furnace. A 110 by 70 cm pit was dug into which the foundation will be poured. Creation of the foundation is necessary if you plan to have the furnace serve you for a long time and efficiently, otherwise in a few years it will crawl resembling the Leaning Tower of Pisa. Also, before starting work, you should clearly determine the location of the solar furnace. Near its foundation there should be no trees or buildings that can obscure it from sunlight. The oven itself should be facing the sun while you are about to cook.

After the place was determined and the necessary hole was dug for the foundation, the author proceeded to create the very foundation of the furnace. The foundation was laid out of old brick and cobblestone. which were cemented together. The height of the foundation was about 30-40 cm.

After the foundation has hardened, the time will come to build the furnace itself. The author decided to make the furnace from a mixture of clay and straw, which is called adobe. Since ancient times, such building material has been used for the construction of houses, sheds and other similar structures. One of the advantages of adobe, which is very suitable for a solar furnace, is that it has a large thermal inertia: after heating, it stays warm for a long time and does not cool down. In addition, this material is always available in the author’s area, is cost-effective and environmentally friendly.

To make adobe, the author kneaded clay in water, and then mixed it with straw. In this consistency, the straw acts as a binder, which does not allow the clay structure to spread. After receiving the mixture, the author proceeded to lay the adobe on the foundation prepared for the furnace. As a result, the height of the furnace was about 80 cm.

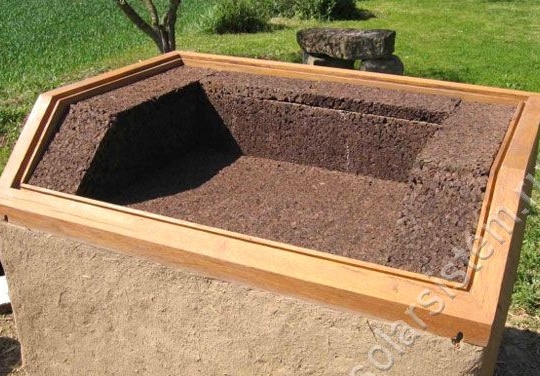

Next, a wooden frame 200 mm high is installed on top of the furnace. It is securely fixed on the adobe using metal pins in the lower part of the frame. the adobe is adjusted to be flush with the wooden frame, and also a recess is made inside, in which the pan for cooking will be placed in the future.

After the main part of the stove was assembled, the author proceeded to improve its appearance. Using the remaining clay, the surface of the furnace was leveled. In order to reduce heat loss in the upper part of the furnace, a heat-insulating material was laid, cork wood, mineral wool and the like can serve as such material.

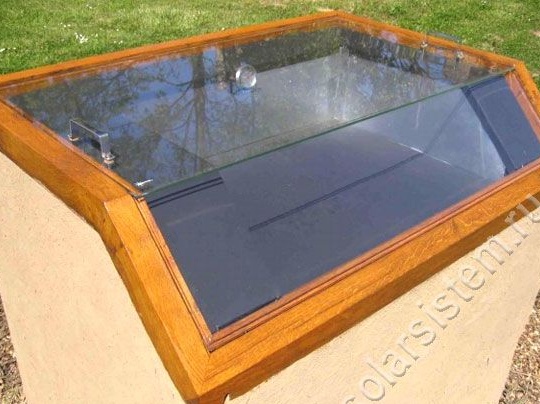

To improve the appearance of the solar furnace, the author ennobled the hob using aluminum sheets, and aluminum is best anodized or painted with heat-resistant paint in black.

The author used glass as a cover for a solar furnace. Already in this form, the temperature inside the furnace can reach 100 degrees. However, the author decided to improve this indicator to speed up cooking. To do this, he attached a mirror reflector, which will direct the sun's rays on the hob. while the temperature inside the furnace began to reach 120 degrees.

The result is an excellent solar-powered oven that is suitable for cooking at certain times of the day. The possibility of cooking only at a certain time, when the sun is standing in a certain place and heats the stove as much as possible, is the main disadvantage of such a stove. The rest of the time, the temperature inside the oven will decrease, although if you want to increase the possible cooking time, you can place additional reflectors that will redirect the sun's rays to the cooking surface.