Another interesting model dryers for vegetables and fruits based on solar energy. This dryer differs from that described in the previous article, a more improved convention and the fact that in this model there is no direct exposure to sunlight on dried products.

The materials that the author used to create this model of dryer:

1) sheets of moisture-proof plywood

2) wooden blocks

3) sawdust

4) mineral wool

5) metal elevator

6) metal corrugation

7) glass

8) mosquito net

Consider the general design of this dryer, as well as the main stages of its assembly.

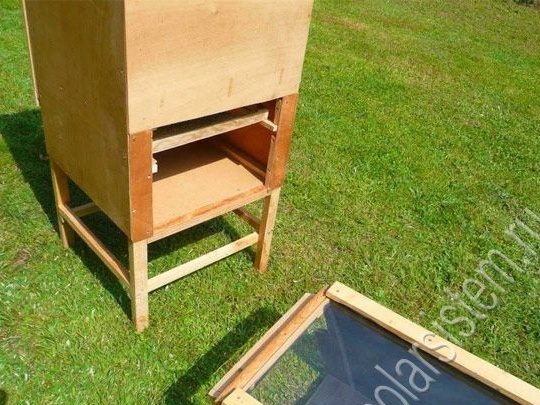

The main part of the drying cabinet will be made of plywood and wooden blocks. Since the cabinet will be constantly on the street, the author decided to use moisture-proof plywood to protect it from the weather.

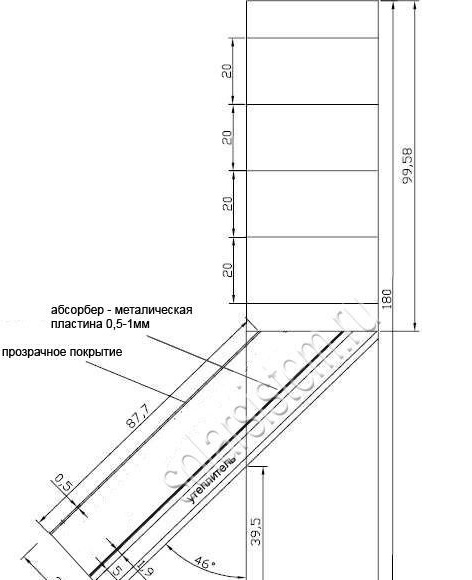

Below is a drawing according to which the main measurements and cutting of parts for cabinet assembly were made.

After all the necessary details were prepared, the author assembled this cabinet from the boards and upholstered it with plywood.

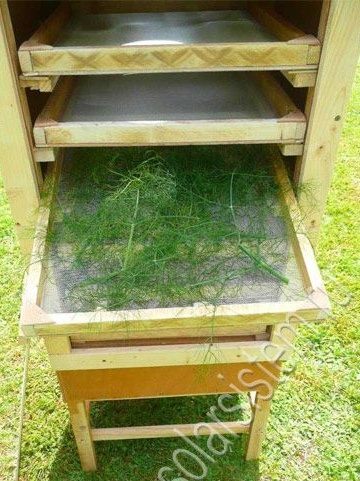

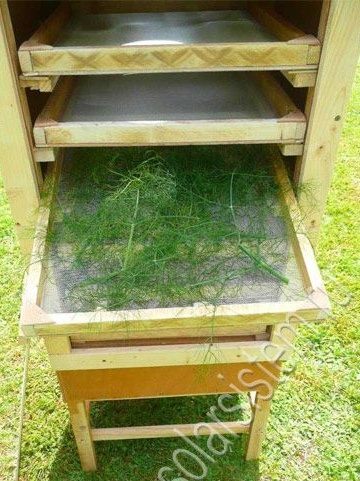

Trays were made for the drying chamber. They consist of wooden bars and a mosquito net stretched over them. Thus, air easily passes through all pallets and the drying of products occurs evenly.

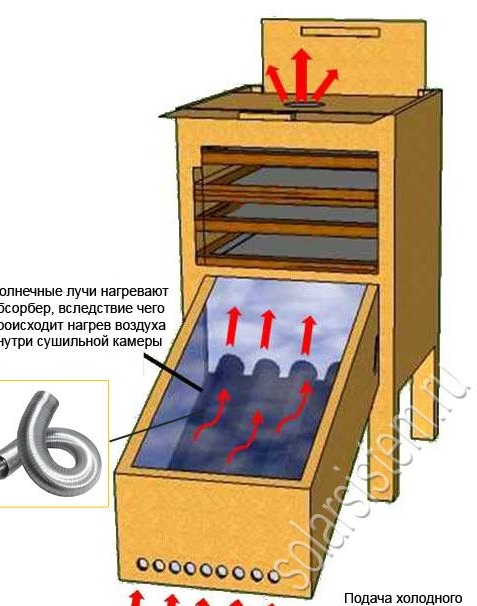

Unlike the previous design, this model of an oven uses an improved air solar collector, in which air is heated. Air enters the collector through the lower ventilation openings, after which it heats up from sunlight and rises up through the frames on which fruits, vegetables and other supplies are dried. Through the top vent, air is removed from the drying chamber.

The solar collector is made according to the principle of a box, on the bottom of which thermal insulation material is laid, in this case sawdust and mineral wool. On top of the insulation, the author put a sheet of thin metal, which acts as an absorber. The metal was painted black with heat-resistant paint. On top of the box was covered with glass.

In order to increase the temperature inside the oven, the author slightly upgraded his solar collector. To do this, a maze of wooden planks was installed between the absorber and the glass, so the air lingers longer in the collector and heats up more. The author is also going to install an aluminum corrugation painted black, due to which the area of the absorber will be increased, and therefore the air will warm up faster both inside the corrugation and outside.

In order for the solar oven to work most efficiently, it must be constantly turned in the direction of the sun. Therefore, to facilitate and simplify the use of the drying cabinet, the author made several more solar collectors that are located on other sides. Thus, the drying cabinet will work throughout the whole sunny day and will not require constant manipulations with changing its position.

After the entire structure was assembled, the author treated it with an antiseptic and painted the oven to protect it from external conditions and increase the life of this structure.