Everything turned out to be simple. Any craftsman has at hand:

So, let's begin; for manufacturing we need: a piece of plywood, a pencil, a ruler, a hacksaw for metal or a jigsaw (I have a circular saw to help), 2 drills (I have 8 and 3 mm), a saw blade or a cutting disc for stone (the main thing is to have teeth), manual or electric drill, file with a large notch.

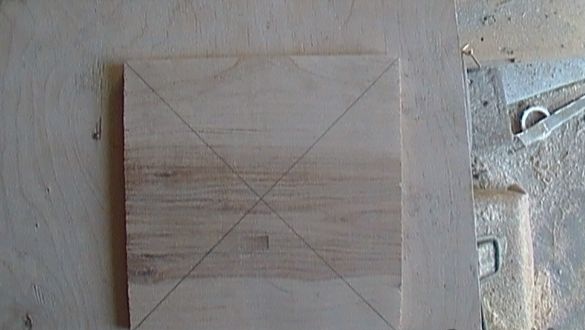

First, take a square piece of plywood, find the middle by drawing 2 diagonals.

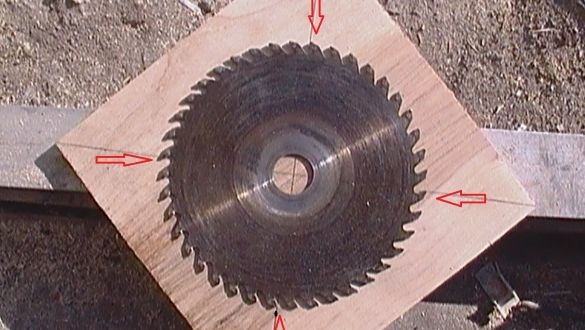

We put the saw blade so that the teeth coincide with the diagonals

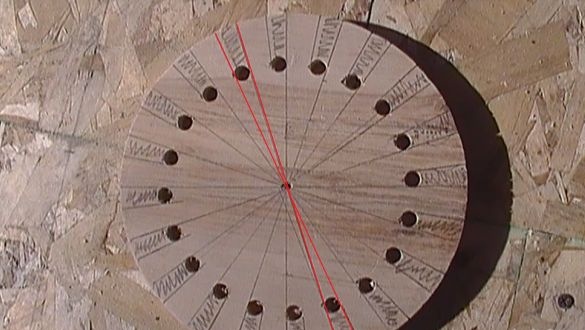

And we drill holes by selecting the "step" for future gear teeth.

Drill the holes obtained up to 8 mm. and with the help of a jigsaw (I did on a circular) we cut out the correct circle.

We draw the lines passing through the center of the circle, connecting the opposite sides of 8 mm. holes and cut out the shaded sectors.

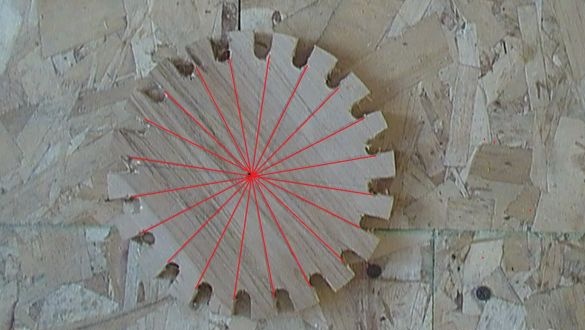

Using a jigsaw or circular, we trim the resulting teeth to the desired length.

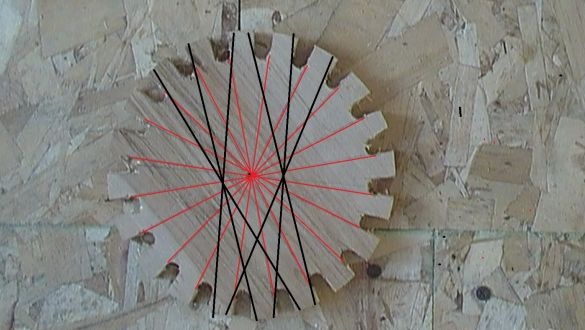

Having drawn lines (black) on the resulting workpiece, we cut the gear teeth.

Next, having worked as a file, we get the finished product

I also need a small gear for the “drive". I made it similarly large, but used a cutting wheel on the stone.

If I have a large gear with 20 teeth, then a small gear with 9 teeth.

Having determined the center on the basis of received gear, which I intend to use in another product.

Good luck in business and research!