Each summer resident at its site in spring or in autumn it encounters such a problem as dry branches on fruit trees and shrubs. Mostly summer residents throw or burn this material. Because they sometimes do not have the strength and the means to process them. But if you chop these branches, you get excellent compost and fertilizer for your garden.

A huge number of garden shredders, twigs, grass and straw are available for sale. But all these units cost money, and sometimes not small for a simple summer resident, and our gardener is used to save and do everything himself, since the family budget does not allow you to take a big step.

The author decided to construct his branch chopper from what he had available. And the author had an old walk-behind tractor in the household. It was on the basis of this unit that our designer decided to assemble a branch chopper.

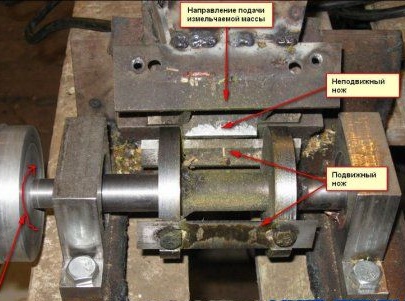

The principle of this design is quite simple, if everything is well understood. The chopping apparatus itself consists of a drive shaft with knives and a fixed knife, due to the torque of the drive shaft with knives, and branches, bushes are chopped into small dust, and wood chips. The drive shaft drives the torque transmitted from the walk-behind tractor through the belt to the pulley of the rotating shaft, thereby driving the grinding apparatus. For the convenience of supplying material to the chopping unit, he welded a receiving hopper from sheet metal, which is very convenient when he simply sent the branch to the hopper, and then slowly push it. That's essentially the complexity of the design, and now let's take a closer look at what he needed and how he constructed his invention.

Materials: walk-behind tractor, electric plane knives, pulley, shaft, bearings, channel, 3 mm sheet metal, bolts, nuts, washers.

Instruments: welding machine, grinder, hammer, set of keys, pliers, drill.

And so, the author first welded the base from the channel, then installed a fixed knife, and the most important part was the drive shaft with knives from an electric planer, the pulley was mounted on a shaft with a cutting device to power it from the torque supplied from the walk-behind tractor via a belt drive.

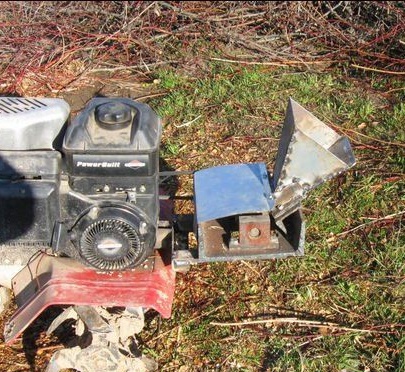

Then he welded and installed a receiving hopper for the convenience of carrying out work on chopping branches.

And then he installed the grinding apparatus on the front of the walk-behind tractor and pulled the belt drive onto the pulley. Motoblock previously put on a stump so as not to leave))).

That's essentially all branch choppers do it yourself ready.The author’s site will now always be clean, and compost will always be available, so necessary for the good growth of vegetables and greens in the beds.