For most residents, a country house is a dream. It is so nice to escape from the stifling embrace of the city streets to the countryside. Fresh air, forest, river ... Therefore, I suggest that you realize one of the workshops on building country house.

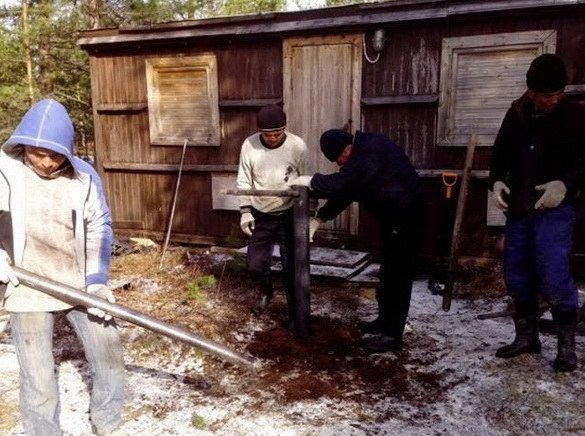

Each construction begins with a project. The author himself drew his project, as he put it "on his knee" and began to realize his dream. A foundation is needed for each building, as it is the basis of the entire structure and the key to strength. The author also began with the foundation. He has it - screw piles. After clearing the place for the construction of the structure, the author begins to make the foundation itself. He himself was not confident in his abilities, so he called a team of specialists.

During the day, the team of specialists managed their task and by the evening the foundation was ready.

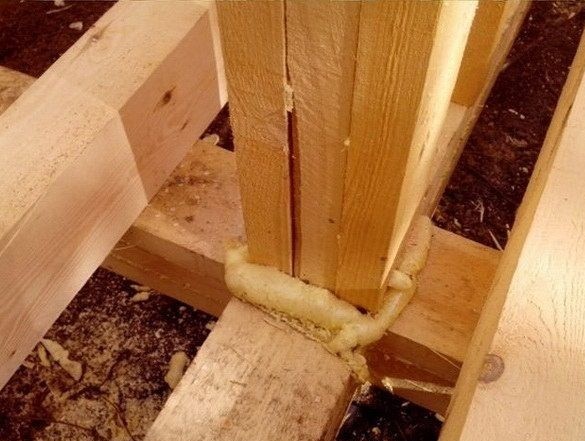

Now, from the purchased materials, we begin to produce corner piles. Since the author of this building does not trust this to the bars, motivating this by the fact that as it dries, it begins to twist. The thickness of the walls in the house will be equal to 150 mm, respectively, and the corner bars will be the same thickness. The author has a board size of 150x50. Therefore, you need to fasten them together, to get a beam measuring 150x150. We cut the desired length of the boards, glue the foam and fasten with nails so that the end comes out and it can be bent like a bracket.

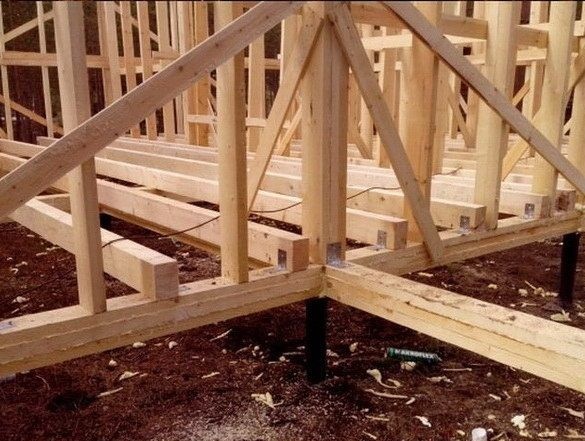

Now the author begins to tie around the foundation. Here it is necessary to set all angles and heights very clearly, because any mistake will interfere with us throughout the course of construction.

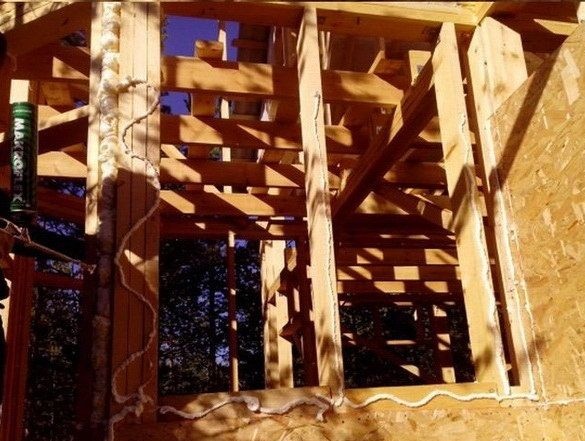

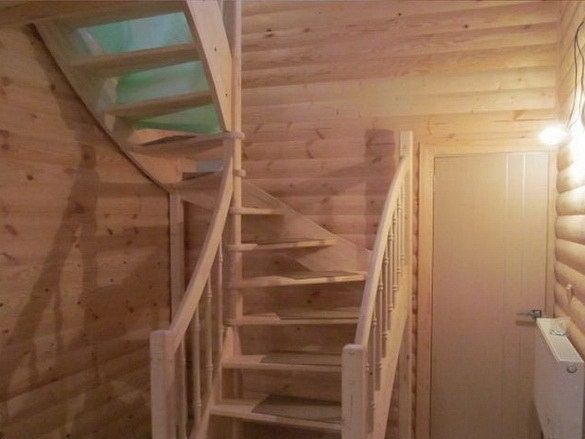

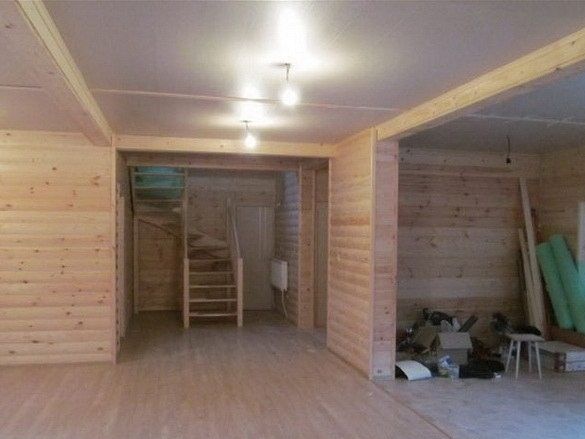

After the strapping is completed, they begin to erect a frame of walls and ceilings of the first and second floors.

The author additionally connected all the connections with building corners and penetrates.

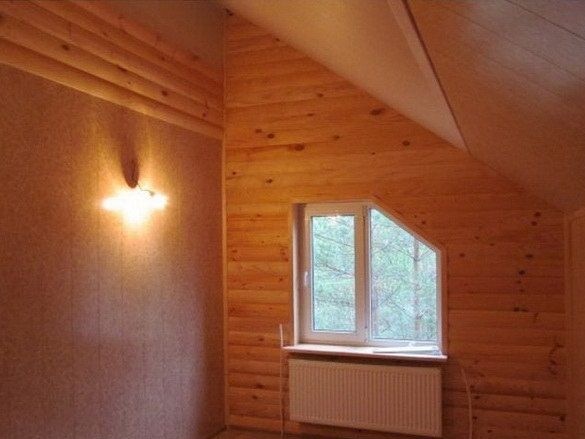

After the walls of the first floor are erected, the author proceeds to the second floor and the roof. The walls of the second floor were built in the same way as the first. The author decided to put a metal tile on the roof.

Further, after covering the roof, the author proceeds to wall cladding.This prevents the wind from blowing into the room, hindering further work and gives the structure structural rigidity. OSB-3 9 mm thick was chosen for the casing.

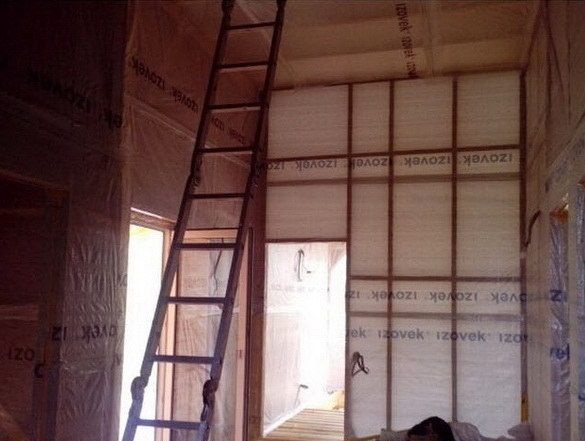

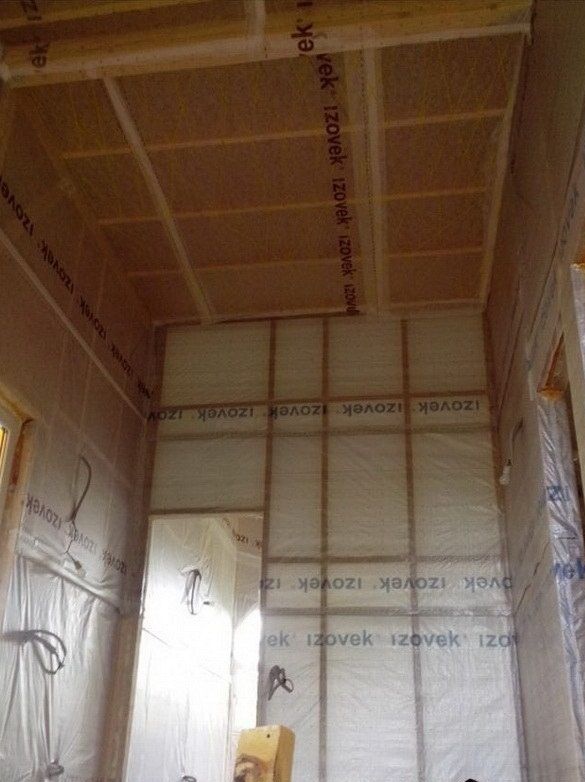

Next, the author conducts an electrician. He pulls the wires in the corrugation. Since the author’s insulation "is not edible for rodents and they won’t get to the wires." There are no connections in the walls. Everything is only in boxes, which simplifies further operation and reduces fire hazard. So it is with plumbing. Next comes the time of vapor barrier.

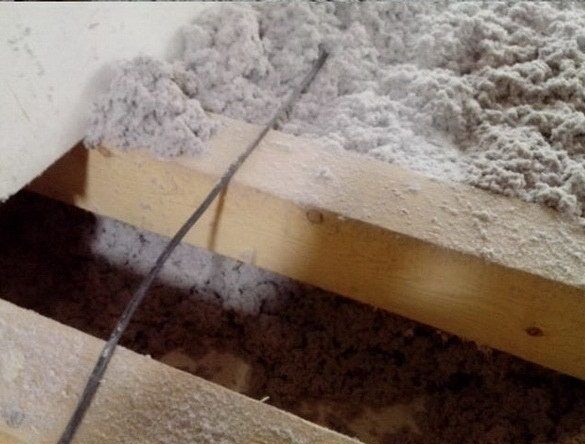

Now comes the time of insulation. Used cellulose insulation, or as it is called - ecowool. This insulation does not cause allergies and, thanks to its fine texture, fills all small cracks and voids well.

[center]

Further it is vapor barrier to the floor and heating pipes. The author uses a fan circuit, that is, in the boiler room there are two pipes from the collector to each radiator - supply and return. And as is the case with the electrics - there are no connections inside the ceilings.

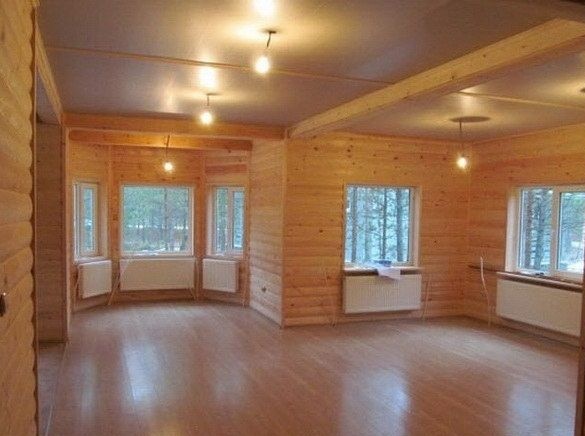

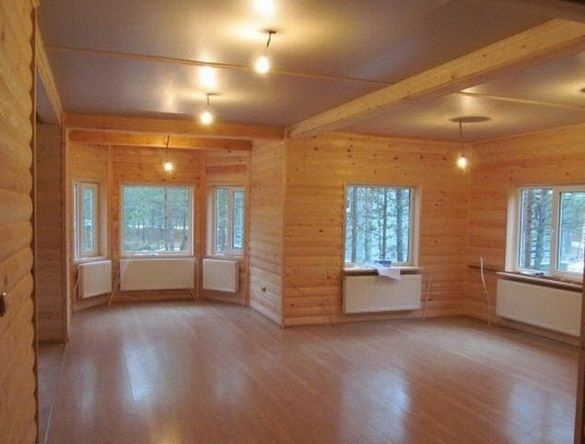

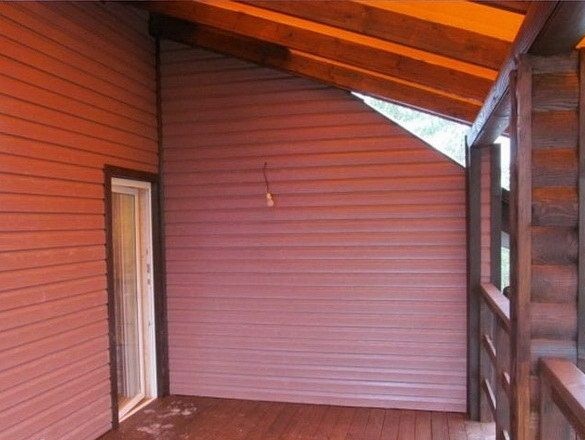

The author made floors from profiled chipboard. When decorating the building, imitation of logs, imitation of timber, MDF panels for walls, PVC panels for ceilings were used.

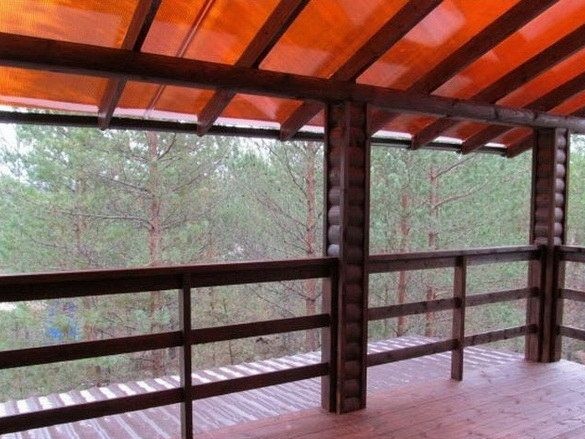

Plates impregnated with terrace oil were used on the open veranda, and polycarbonate was used on the roof 12 mm.

The sauna was sheathed with a lining, under a neufolgirovanny vapor barrier, as well as a power cable for connecting the stove.

As a result, we got such a cool country house, in which you can generally move to a permanent place of residence!

I wish you the realization of their housing dreams)