Each person who has acquired a small plot of land for a summer residence seeks to build a house in a short time, or a similar easily-erected structure. To have a place where to relax after a hard day's work, or to shelter from inclement weather. Well, it’s natural to get settled in a domestic way. Of course, it is advisable to build a house to accommodate the whole family, and guests who came for the weekend. The task is of course a grandiose, but quite feasible, if you have accumulated savings for the construction of a country house, because a large amount of new building material will be required.

If possible, you can hire wage workers to build this building.

Of course, this will significantly increase financial costs for your family, and if there is no such opportunity, you will have to build country house do it yourself.

Basically, the owners of cottages build their houses with their own hands, in order to save money for hiring a construction team and invite relatives and friends to the construction site for help, which naturally reduces the cost of the construction process.

Even summer residents sometimes use second-hand materials that can be purchased at half price compared to market prices, but this will reduce the durability of the design, also by half.

When constructing his country house, the author decided not to save on basic material and to buy everything on the construction market, so that he would be enough for a century and stood there for a long time, pleased his family and his guests with its cosiness and aesthetic appearance.

Of course, wood was chosen as the main material for the construction, which can be better and more beautiful than wood. The author bought bars and boards at a local sawmill, which turned out to be much cheaper than in a hardware store.

Getting started building pre-drilled wells under load-bearing posts, inserted and poured cement mortar. He made the binding of the posts with boards and left for a day to dry the solution. Then he began construction, walking step by step towards his cherished goal.

And so now, let's take a closer look at how he built his country house, and what he needed for this.

Materials: board 30 mm, beam 100 to 100, beam 40 to 60, floorboard 50 mm, insulation, prof-sheet, rail, fiberboard.

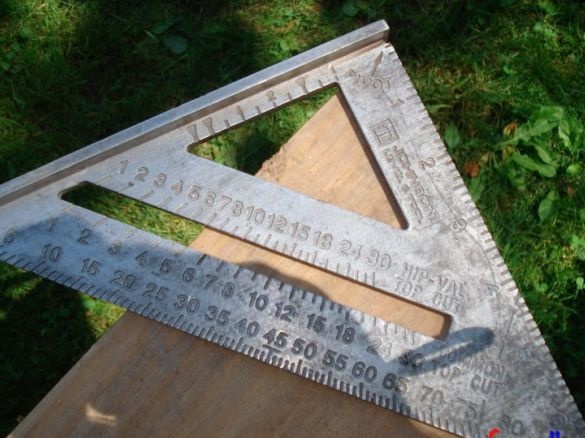

Instruments: circular saw, drill, drill, screwdriver, hammer, shovel, electric planer, angle, ruler, tape measure, circular cutting saw.

And so the first thing he invited a neighbor and together they drilled wells for installing poles.

Then he set the posts, and poured the pits with cement mortar.

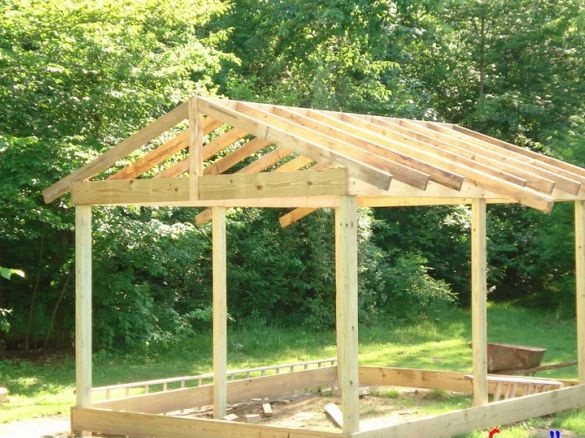

He made a screed at the top and bottom, so that the pillars stood evenly, after a day after the solution had gained hardness, he began further construction.

The author makes the upper binding.

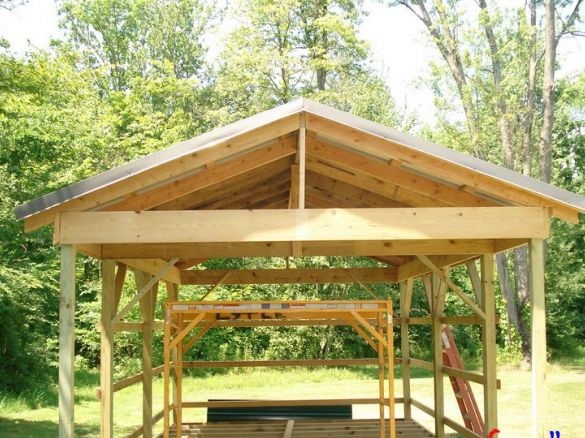

Then proceeds to create a roof ridge.

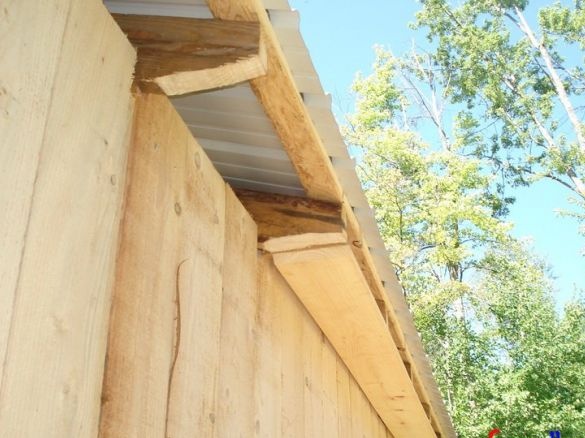

Next, makes a roof crate.

Shows the rafter mount.

Remains from sawing also come in handy somewhere.

Next, proceeds to the installation of the roof from a professional sheet.

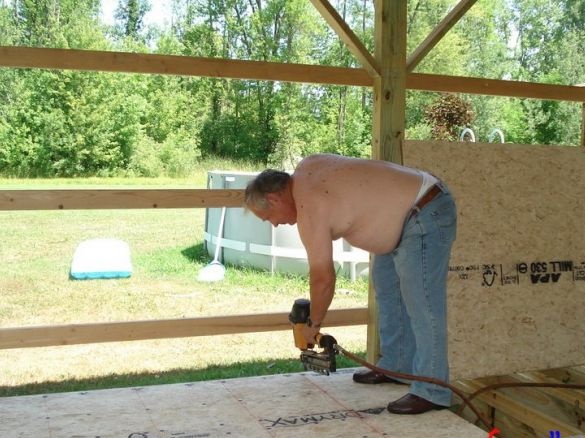

Then proceeds to the device floors of the house.

So it turned out a place to store boards from precipitation.

Prepares a batch of boards, dissolving them on a circular saw.

And proceeds to finish the cornice.

Sheathes the walls with boards, and closes the gaps between the boards with slats.

Next goes to the ceiling lining.

The author is also sawing planks for covering the porch.

And the main work is completed, the house is built, goes to the insulation of the walls with mineral wool.

I inserted the windows and doors remaining after replacing the apartment with new ones.

The gaps between the boards, closes with slats.

That’s actually a cottage built on its own. The author is very pleased with his construction. In a short time, the built house will shelter the author and his family from the inclement weather for the weekend.