In total, the article will consider two options for how to make a straight-through muffler.

Materials and tools for manufacturing:

- a pipe, the diameter is selected depending on the brand of car (a diameter of 52 cm is usually placed on a VAZ);

- welding;

- Bulgarian and disks for metal cutting;

- iron sponges for washing dishes (50-100 pcs.).

The process of manufacturing a straight-through muffler based on the standard:

Step one. We remove the muffler

First of all, you need to remove the muffler from the car. As an example, a VAZ car is considered. Next, a grinder is taken and a piece is cut out in it, as can be seen in the photo. Subsequently, all the inside of the standard silencer is dismantled.

Step Two We make a silencer pipe

Now you need to make a pipe that will play a key role in the exhaust pipe silencer. In it, you need to cut a number of slots in the form of a Christmas tree with a grinder. You can also drill holes with a drill. The sound of the muffler will depend on the order of the holes and their number, as well as size.

Step Three New tail

The tail must be cut off, a new tail is installed in its place. The length of the new tail will be 50 cm. Next, you need to try on this whole thing and put two welding points, in the end we check that everything is smooth. Further, the entire space is clogged with metal sponges and the silencer is finally welded. In conclusion, it can be painted.

According to the author, at engine speeds of 2500-3000 rpm, the sound of the engine in the cabin is not heard. At higher speeds, the sound is already audible, but it is not as bass as the "banks". From the side, such a muffler looks like a standard, but a little longer.

Another way to make an exhaust pipe silencer

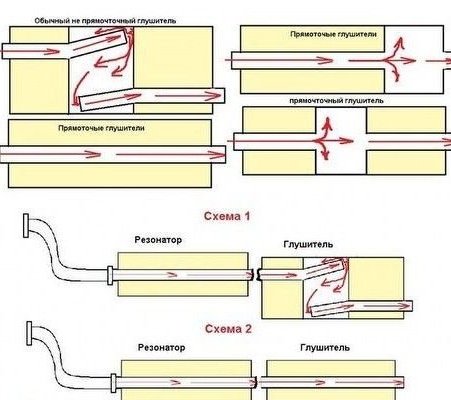

There is another option to make a straight-through muffler, only individual elements are used here. Most often, two schemes for manufacturing such silencers are used. Diagram # 1 shows a back-flow exhaust, and Diagram # 2 shows how a sport exhaust pipe muffler works. It is precisely such a sample that this muffler will be made.

Step one. Work Turner

To make such a silencer, a turner needs to order two flanges for pipes (130 mm and 42 cm perforated pipe with a diameter of 2.5 mm). The pipe was bent from a 2 mm sheet.

Step Two Wind the pipe

The perforated pipe must be wrapped with refractory material. Asbestos is suitable for these purposes. This is done in order to protect the glass wool from burning out, since very high temperatures will form during operation.

Step Three Final work

At the edges you need to thoroughly stuff mineral wool or glass wool (between the perforated pipe). Now it remains only to weld the muffler and can be set.

That's all. In such simple ways you can make a straight-through muffler. After installing such a silencer, the sound will become much louder. If the task is to increase power with the help of such a muffler, then without additional modifications to the exhaust system this is unlikely to succeed. To get an additional amount of horsepower, you will need to modify the intake, ignition and power systems. Only in this case will there be any results from the forward flow.

Savings in the manufacture of such a direct-flow do-it-yourself will be about 3,000 rubles, of course, with the availability of tools, materials and experience creating such homemade.