Metal detector built on the principle of disrupting the synchronization of two coils. It is because of such an interesting design that looks like a butterfly, the device got its name. Homemade easy to assemble, and all components are easy to get.

And now about the most important thing, to what depth is this miracle of technology capable of seeing. According to the author, the five-copeck coin of the USSR is found at a depth of 15 cm, which is a pretty good indicator. The device sees the metal cover from the can at a depth of already 30 cm, and the device detects such a massive object as a metal hatch at a height of 60 cm.

The metal detector can work in water, and one battery charge lasts 20-30 hours. The current consumption is 15 mA, the device weighs only 500 grams. The device can be configured for any soil. There is also a simple discriminator, the type of metal can be determined by what sound is fed into the headphones.

Materials and tools for manufacturing:

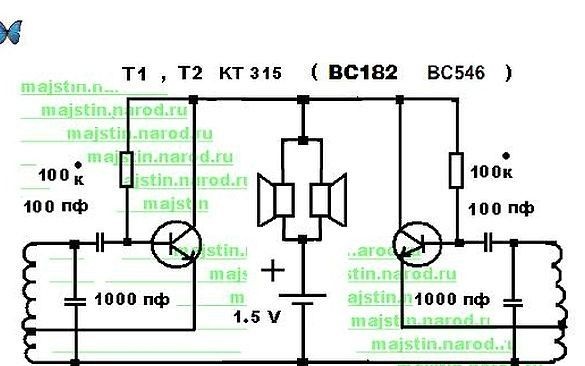

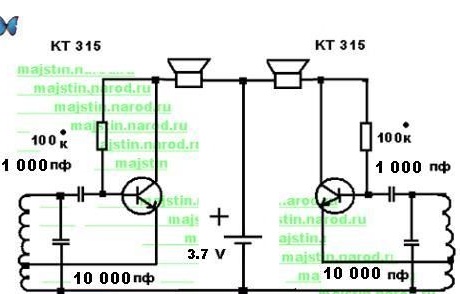

- two transistors KT315 (BC182, BC546 ...);

- two capacitors 1000 pF (1 nF or 102);

- two capacitors 10000 pF (10 nF or 103);

- stereo headphones;

- two resistances per 100 kOhm;

- one battery from a mobile to 3.7V;

- wire type PEV or PEL with a diameter of 0.5-0.7 mm in varnish insulation;

- soldering iron and other tools;

- materials for the manufacture of the housing.

The process of manufacturing a metal detector:

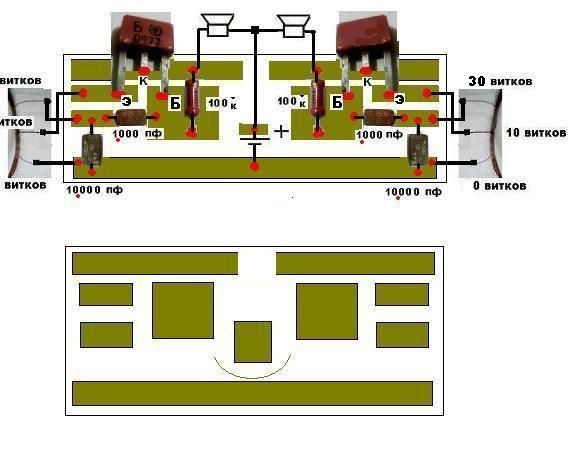

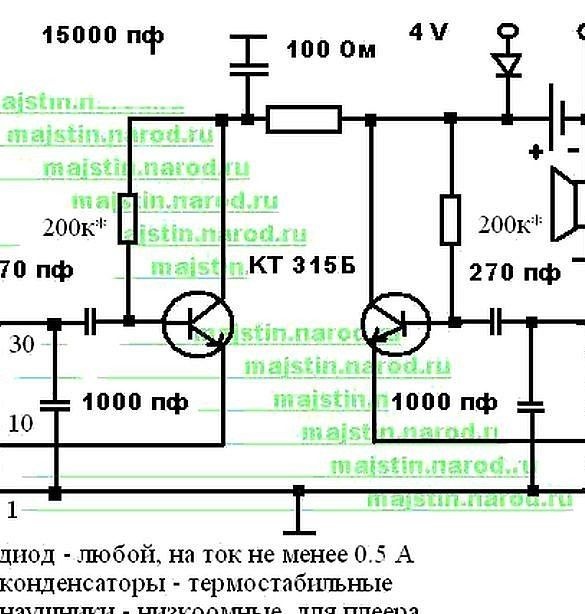

Step one. Device diagram

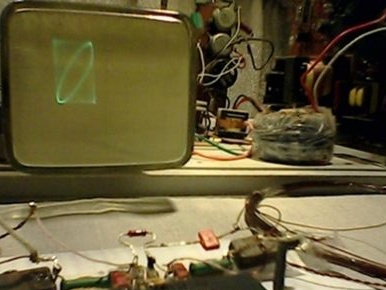

The scheme is not too rigid, so it is not necessary to strictly observe the number of turns, the rating of the parts and the power source. The most important condition is the identity of the right and left sides. Interference during operation is compensated, and the soil does not affect the quality of work. If the circuit is assembled symmetrically, it works immediately. Signals from the generators are fed to plates X and U.

The picture shows that the frequencies coincide.

In case of disruptions in the headphones, clicks begin to appear.

Now the generators are out of sync.

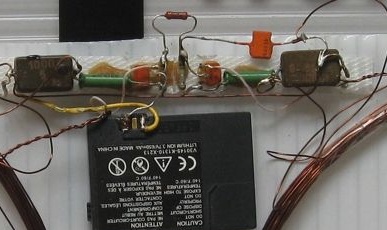

Step Two Board assembly

Any glue that does not conduct current is used to connect parts. The battery must always be charged and have good capacity, otherwise the setting will constantly go astray. For these purposes, you can use one or two batteries from a mobile.

Capacitors should be used mica, not sensitive to temperature extremes. If there is no textolite, the board can even be made of cardboard.

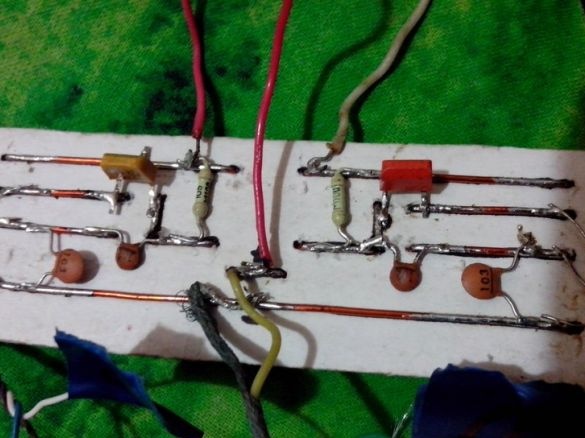

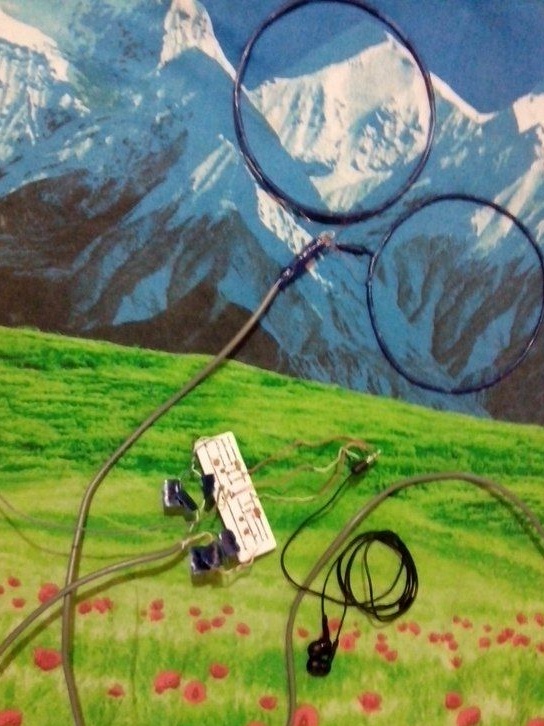

Step Three We reel

The first turn of the coil is soldered to the negative of the battery.Next you need to reel the coil, for example on a saucepan, after ten turns you need to make a loop. Here, the wire needs to be stripped and soldered to the emitter of the transistor, that is, the middle tap in the circuit. Next, you need to wind the last 20 turns, subsequently this wire is soldered to the connection of two capacitors 10000 pF and 1000 pF. In this way, you need to collect the second coil.

Step Four Metal detector housing

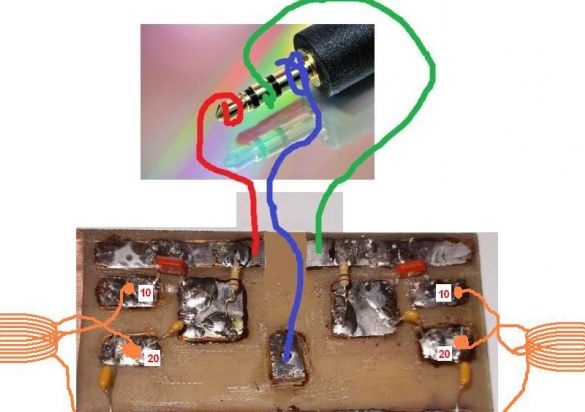

For the manufacture of the rod, you can use a metal-plastic water pipe, the rod must be made collapsible. Pipes 20 and 26 tightly enter one another. Coils and circuits for protection against moisture are coated with oil varnish. Coils are glued at a distance of 10 cm.

Step Five Customize the metal detector

When you turn on the metal detector, a squeak should appear in the headphones. If it so happens that the circuits are not the same, some configuration will be required. There are two ways to configure the metal detector, that is, to synchronize the generators. The first is that a large sheet of metal is brought to each coil, while under one of the coils the squeak should stop. On this coil, you need to bend the last turn inward. Or you can simply increase or decrease the distance between the coils until the sound becomes very quiet, or does not stop at all. On top of each coil, you need to glue the tubes with ferrite, then you can adjust the metal detector with a ferrite rod to complete silence.

The next method is to configure the device with a ferrite rod. A tube is glued to the coil and a rod is inserted into it. Next, ferrite must be moved until the sound in the headphones stops.

You can also adjust the device with pieces of aluminum plates that are glued inside or outside the coils. Stripes are placed on coils and move to a complete lull in the headphones. If clicks are heard in the headphones, this indicates that the metal detector is operating at the maximum level of sensitivity.

In addition to adjusting parallel to the 1000 pF capacitor, you can install a variable capacitor, which can be found in radios. That's all, after synchronization you can start searching.