Quite often for making homemade it requires a lot of use of sandpaper to finish your product. Given that the process of sanding takes a lot of effort, you can try to facilitate it by making a convenient grater for sandpaper. The main advantage of this tool is its ease of use, the grater lies comfortably in your hand and holds sandpaper firmly, and there is no difficulty replacing the paper.

Materials and tools:

- Pieces of multilayer plywood (thickness 16mm)

- Screw, wing nut and washer

- Thin nails

- Drill with drills

- Chisel

- Thin pieces of rubber

- glue

- epoxy resin

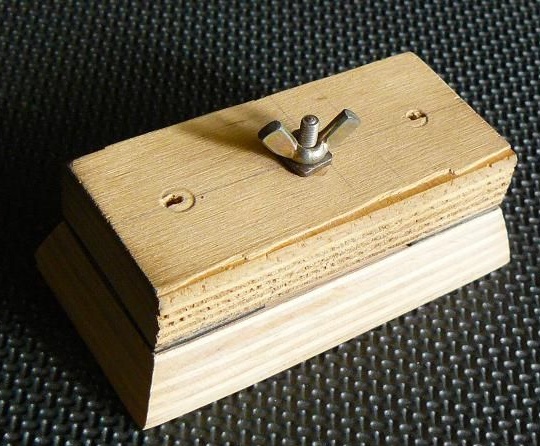

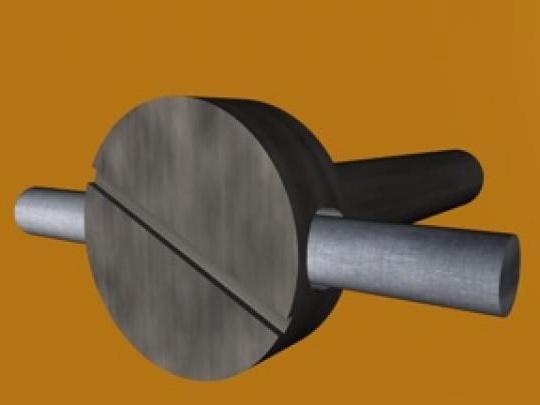

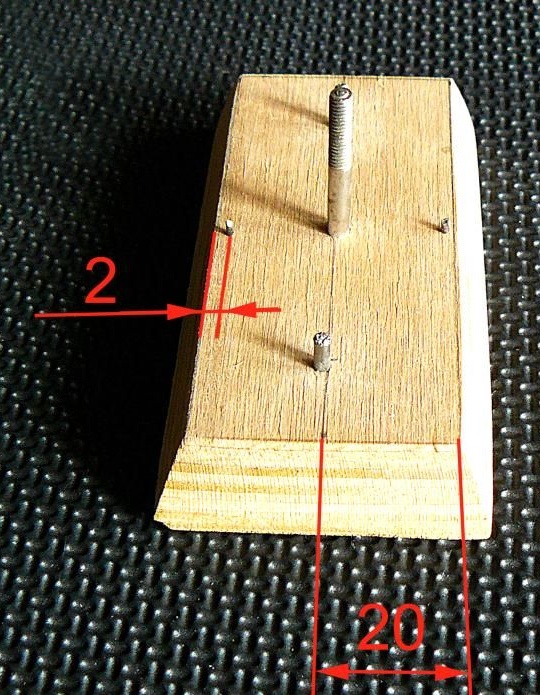

This tool is made of two parts, one of which is the base, and the second is a clamping holder. These two parts are connected by a screw having a wing nut.

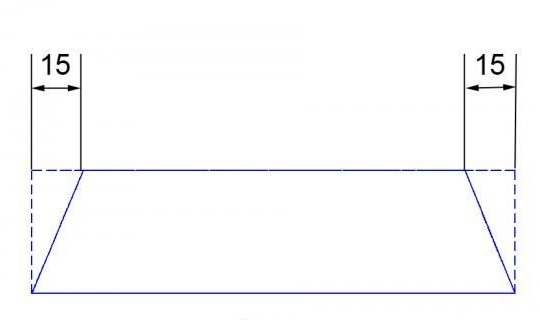

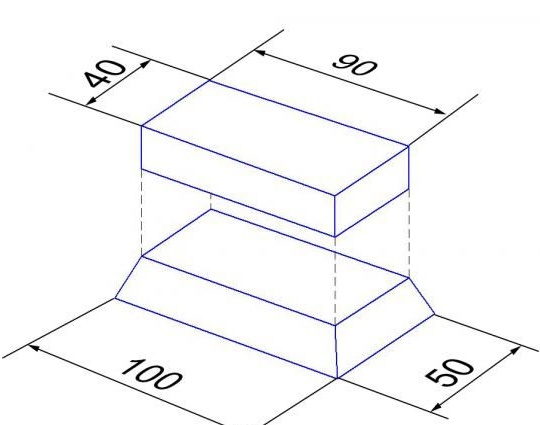

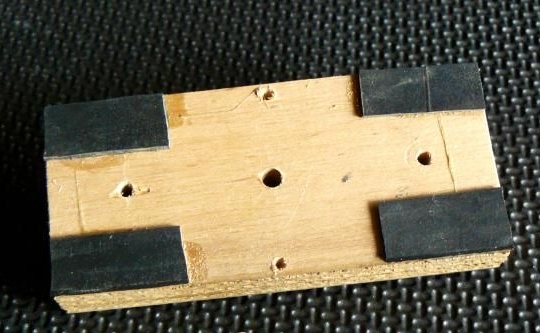

The base is made with equally beveled ends on all sides.

The author made the holder equal in size with the upper plane of the base.

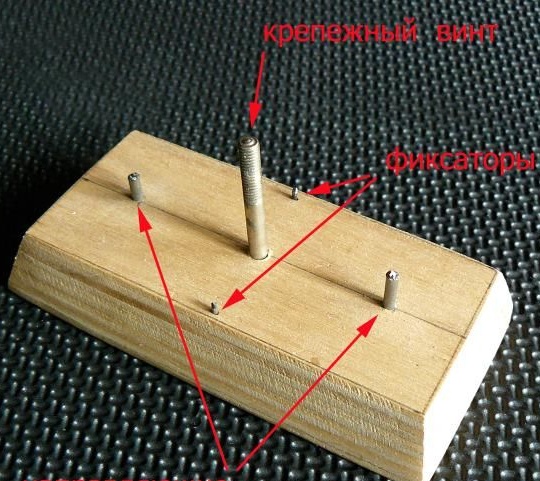

To fasten the two parts of the homemade product, the author installed a screw with a wing, the screw diameter is not indicated, any available one can be used, however, the length should be about 4 cm. A through hole is made in the base and holder with a drill bit slightly larger than the screw diameter. On the side of the sole of the base, the author drilled a hole so that the screw head could completely hide. Also in the screw head, he drilled a hole for a stud, which will act as a stopper. A hat with a clove bites.

In order that cloves do not interfere, a spitz is made on both sides of the screw head.

For a spitz, you can use a grinder or an ordinary chisel. When the screw with the stopper completely went into the nest with a spitz, the author filled the cavity with epoxy resin. You can also use epoxy glue. After waiting for the resin to harden, the protruding part was cleaned with sandpaper.

To strengthen the holder's stability, guides are made.

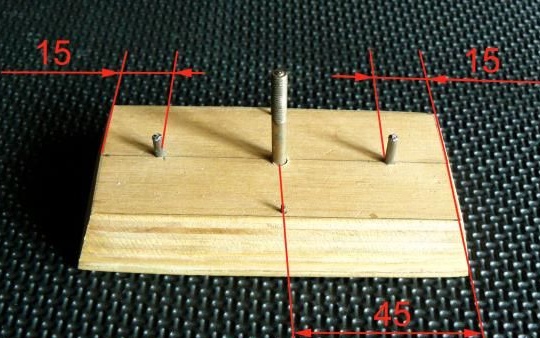

The holder is mounted exactly on the base, screwed with a lamb through the washer. Two nails for guides are selected (their diameter is 2-2.5 mm).The author picks up two drills, one with a diameter slightly smaller than the diameter of the stud, and the second a little larger. The first drill in the base through the holder made through holes for guides. The carnations are driven into the holes just made, and the hats bite. Now the author proceeds to the holder, from the base side, with a second drill, drills holes for the guides to enter.

For high-quality sandpaper pressing, the internal corners of the holder are equipped with thin rubber, pieces of rubber are fixed with ordinary superglue. All irregularities and protrusions of the rubber are cut so that they are flush with the bar.

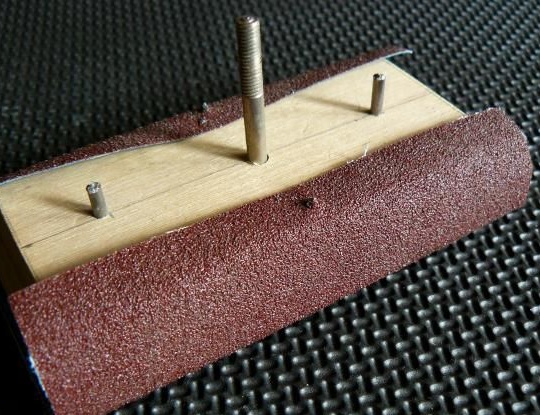

Now, the author can only install the sandpaper clips along the long side of the base. Carnations became cloves with a diameter of 1 mm.

Cloves bite at a height of about 2-3 mm from the base. Putting on the holder, small marks from retainers remain on its inner side, their author has expanded and deepened with the help of an awl.

Now it remains only to put on sandpaper, and get to work. Taking a piece of paper 10 x 10 cm in size, one side is pierced with a latch, the base is turned with an emery cloth, and the second edge also clings to the latch. The holder is put on top and clamped with a lamb. In this form, the tool is suitable for work.