People discovered the ability to knit wool about 8,000 years ago. At first, people used the found pieces of wool for felting, then with the domestication of animals the wool began to be cut. The first workshops for the manufacture of felt appeared in the 16th century, and in 19 the first machines appeared.

With dry felting, a piece of wool is repeatedly pierced with a special needle, the fibers are woven with each other, compacted, and thus the wool is shaped. Occupation is interesting, but rather laborious with the manual method of felting. The author decided to mechanize the process by redoing the old children's sewing machine.

Materials and tools for manufacturing:

- Electric sewing machine;

- Power supply with rheostat;

- the wire;

- button from an electric bell;

- screwdriver, pliers, knife;

- a small cutting machine.

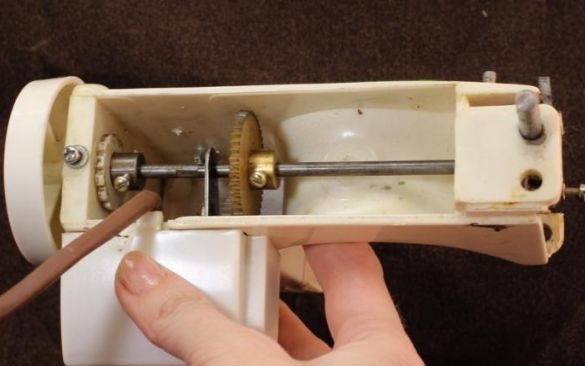

According to the attached scheme, you need to dismantle all unnecessary parts:

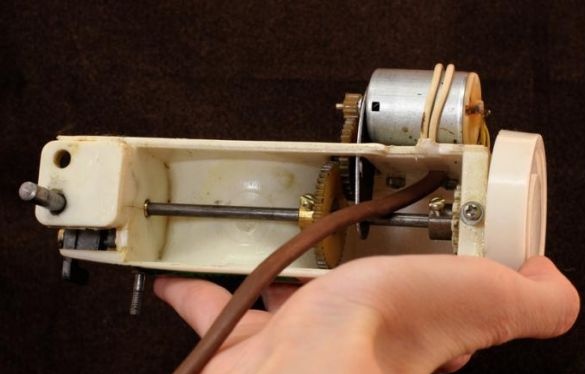

Unscrew the lower part, remove the protective cover, dismantle the presser foot, thread take-up, presser lifting mechanism. Remove everything except the needle bar and electric motor with drives connected to the needle bar. If it is impossible to unscrew any part, the author simply cuts it off with a cutting machine.

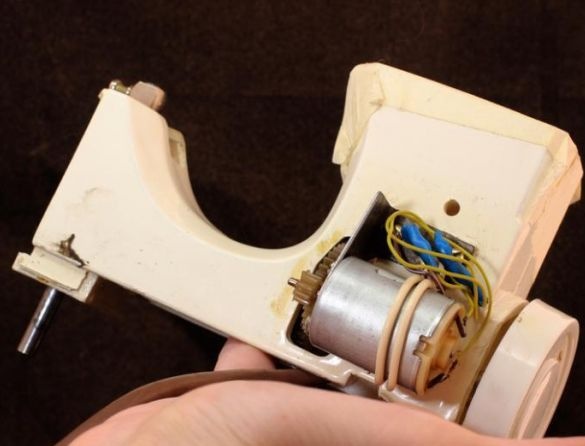

Then, removing the casing from the motor, the ends of the wire are soldered to the contacts.

Then a doorbell button crashes into the chain, which will serve as a foot pedal. To do this, having measured a sufficient length of the wire, that would get to the floor, screw the ends of the wire to the bolts and fix it with nuts.

For safety reasons, closes the hole at the bottom with cut-out cardboard and fixes with electrical tape.

The power supply connects to the other end of the wire. Replaces the engine cover and the machine itself

Now the author has bitten off part of the needle for and inserted it into the needle bar, fixes it with a screw.

All the machine is ready, we can see the result of the work on the video.

As the author notes, the machine turned out much better than industrial designs. The advantages include power, adjustable speed, a greater depth of immersion of the needle and less vibration.