A band saw for wood is a necessary tool in a carpenter's workshop. With the help of such a machine, you can make straight and curved cuts. Evenly cut a wooden blank or cut along the contour of a drawing, all this can be done on such a machine.

The main part of such a machine is a band saw, which is a closed steel strip. On one side of her teeth are located.

It was such a machine that our author decided to make.

Tools and materials.

band saw;

10mm plywood sheet;

two car pumps;

bearings;

1.5 kW engine .;

300μF capacitors .;

profile pipe and corner of different sizes;

welding machine;

locksmith tools;

fasteners.

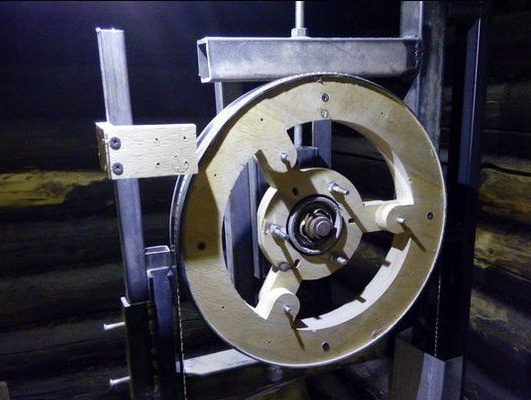

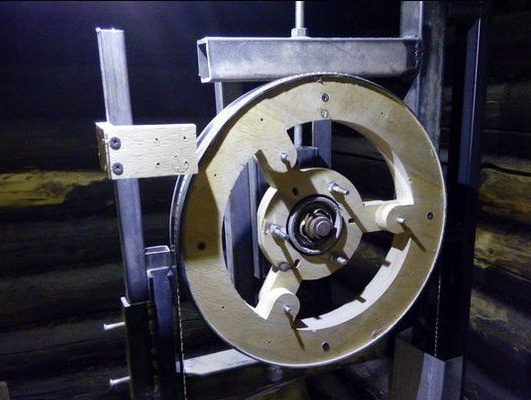

He cut 3 circles with a diameter of 30 cm from plywood 10 mm thick. He glued them together. Cutting out a strip of rubber from an old car camera, it pasted a wheel around it in a circle.

In the same way, I cut a shaft mount from plywood and fastened it to the wheel. The shaft was taken from an old automobile pump from a VAZ 2109.

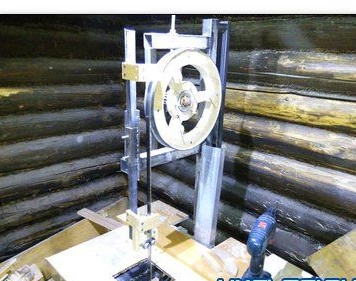

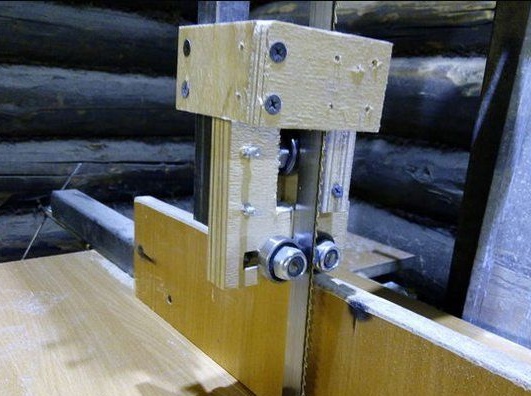

From a profile pipe by homemade made a bed. So that the saw would not jump off the wheel, I installed a guide, making it from plywood and fixing it on a profile pipe.

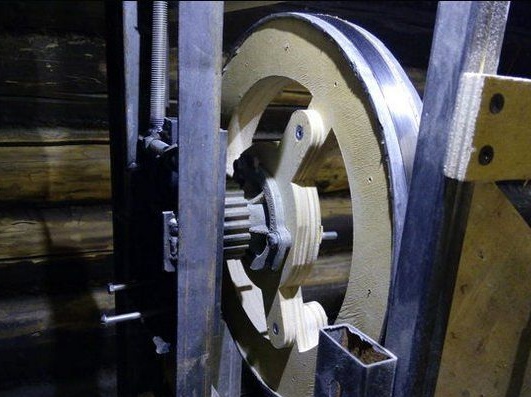

Made of the twentieth pipe, angle and long bolts the centering and tensioning mechanism. By twisting the bolts, you can change the wheel position up and down, left and right. Secured the wheel by welding the pump to the centering mechanism.

Taking a 1.5 kW engine, it collects 300 microfarad capacitors for it.

Installs the engine on the bed, puts the belt.

He took a band saw for cutting meat and improved it by cutting off every third tooth. This gave an increase in speed and power.

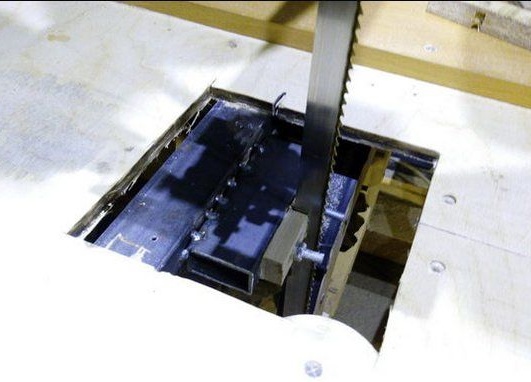

After the band saw is installed on the impellers, you can install the countertop. It must be collapsible in order to change the saw.