The article will consider an example of how do it yourself and in the shortest possible time you can make a simple steam generator. Such a device is capable of generating an electric current from almost any fuel, everything that burns will be used. It can be sticks, hard alcohol, a candle, bark from trees, dry grass and more. You can take a similar generator with you when you go camping. From it you can charge a mobile phone or light a couple of LEDs for lighting.

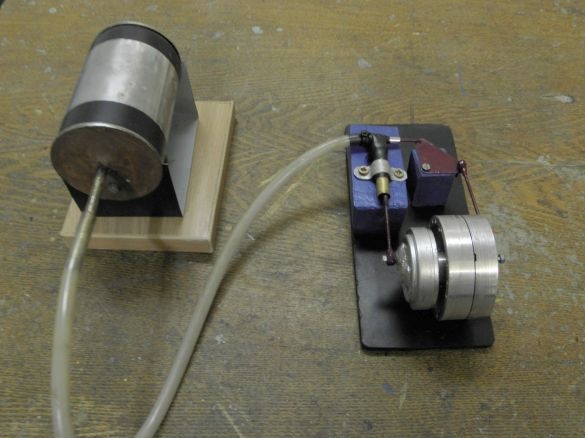

The engine is single piston, with a spool.

Materials and tools for assembly:

- a piece of tube from a television or radio antenna with a diameter of at least 8 mm;

- a small tube to create a piston pair (can be bought at a plumbing store);

- copper wire (diameter 1.5 mm, can be found in coils or buy);

- nuts, bolts and screws;

- lead for the manufacture of a flywheel (can be found in old car batteries, fishing gear or buy);

- bars of wood;

- needles from a bicycle;

- plywood or textolite to create a stand;

- a tube;

- a can of olives or the like.

Of the tools you will need: a hacksaw, emery, soldering iron, epoxy, cold welding, superglue, drill.

The process of manufacturing a steam generator:

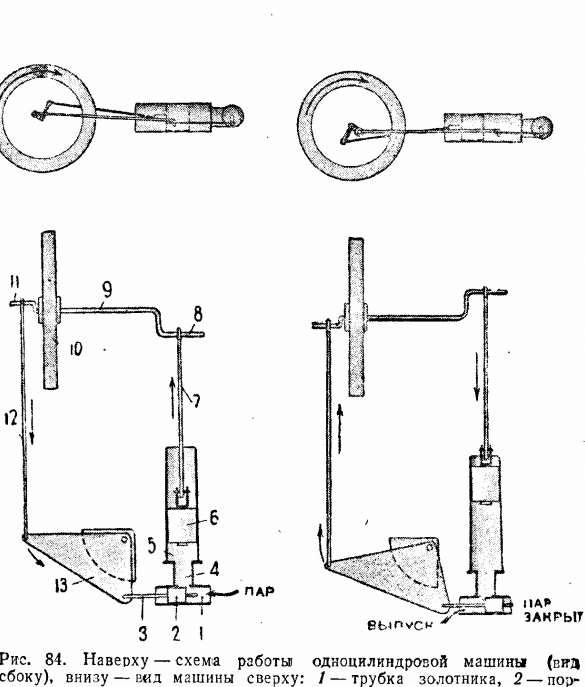

Step one. Schematic diagram of the generator

In the diagram you can see how the mechanism works. That is, it is a crank that is connected to a piston through a connecting rod. The system also has a valve (spool) that opens and closes one of the two channels. When the piston is at bottom dead center, the spool opens the channel and pressure vapor enters the cylinder. Reaching top dead center, the spool shuts off the steam supply and opens the cylinder to let the steam out, the piston then lowers. The reciprocating motion in the classic converted crank into rotation of the generator shaft.

Step Two How to make a cylinder and spool tube

Three pieces must be cut from the antenna tube, the first should be 38 mm long and 8 mm in diameter. It will be a cylinder. The second piece should be 30 mm long and 4 mm in diameter. The third piece should be 6 mm long and 4 mm thick.

In the second tube, you need to make a hole with a diameter of 4 mm, it should be centered. The third tube must be glued perpendicularly to the second, for this superglue is used. When the glue dries, everything is smeared on top with cold welding.

A metal washer must be attached to the third piece, after drying it is also necessary to fix everything with cold welding. When the welding has dried, the seams must be treated with epoxy on top for maximum strength and tightness.

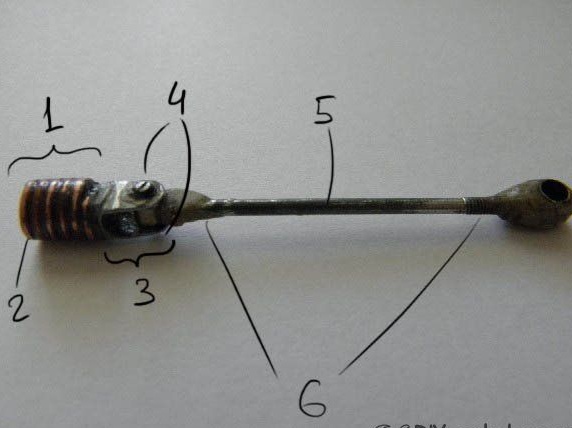

Step Three Manufacture of piston and connecting rod

The piston is made of a bolt with a diameter of 7 mm. To do this, you need to fix it in a vice and wind a copper wire on top, in total you need to make about 6 turns, depending on the diameter of the wire. Then the wire is impregnated with epoxy resin. The excess edge of the bolt can be cut off. Further, when the resin dries, you will need to work with sandpaper to adjust the piston to the diameter of the cylinder. As a result, the piston should move easily, but it should not let air in.

To mount the connecting rod on the piston, you need to make a special bracket, it is made of sheet aluminum. It must be bent in the form of the letter “P”, holes are drilled at the edges, the diameter of the hole must be such that a bicycle spoke can be put into it. The bracket adheres to the piston.

As for the connecting rod, it is made of a bicycle spoke, pieces of tubing from an antenna 3 mm in length and diameter are installed on its edges. As for the length, the distance between the centers of the connecting rod is 50 mm. The connecting rod is pivotally connected to the piston using a “P” -shaped bracket, as well as a piece of bicycle spoke. To prevent the needle from falling out, it must be glued from both ends.

The connecting rod of a triangle is made in a similar way, but here on one side there will be a piece of knitting needle, and on the other a tube. The length of such a connecting rod is 75 mm.

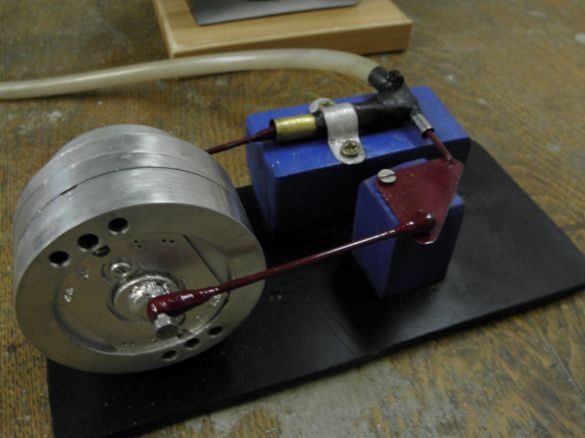

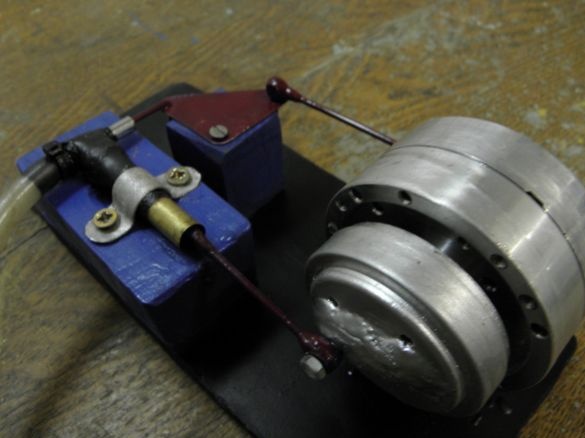

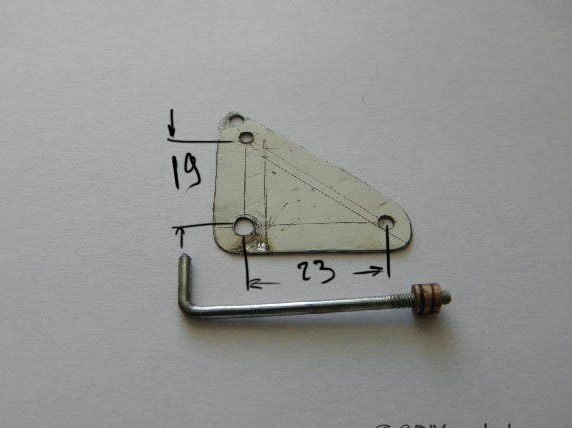

Step Four Spool and Triangle

The triangle must be cut out of a sheet of metal; three holes are drilled in it. As for the piston of the spool, its length is 3.5 mm, it is necessary to achieve its free movement in the tube of the spool. The length of the stem can be different, it all depends on the flywheel.

Supports are best made from bars, they are selected individually. As for the piston rod crank, it should be 8 mm, and the spool crank is 4 mm.

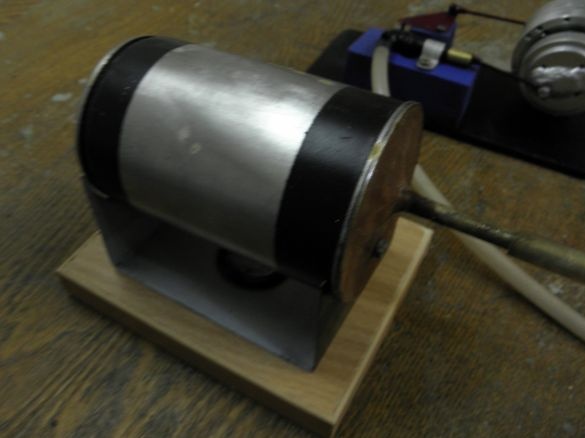

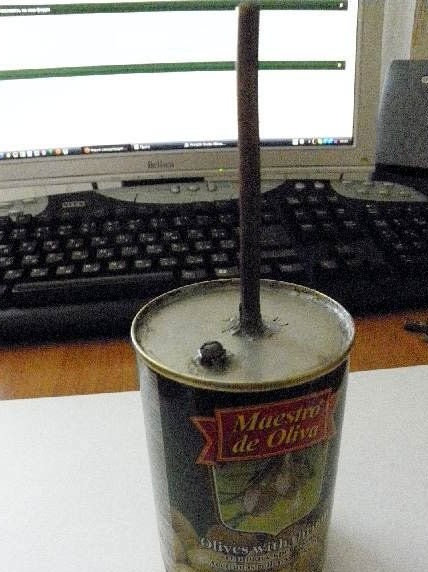

Step Five Steam boiler. The final stage

As a boiler, the author used olives punk with a sealed lid. So that water can be poured into the boiler, a nut must be soldered to the lid, a bolt is used as the lid. Solder the tube to the lid.

Subsequently, the engine is assembled on a wooden platform, supports are used for each element. How the engine works can be seen in the video.

Below you can see what the engine will look like if you modify it a bit. The tank now has an individual platform, as well as a saucer on which dry fuel is placed. Auto recommends using a primus or an alcohol burner, which you can do yourself, as a heat source. All elements can be painted to your taste.