Sometimes in production homemade there is a need to warm up, or even melt, any part or material. Many models of burners can be purchased in stores, but what kind of master will not try to make the tool he needs do it yourself.The author of this homemade decided to make a gas burner from improvised materials.

Tools and materials

indoor antenna from the TV;

jar of baby juice with a lid;

aquarium compressor (external) with a hose;

drill ;

drill;

file;

soldering iron;

nail 120;

needle for the ball;

head-key on 4.5.

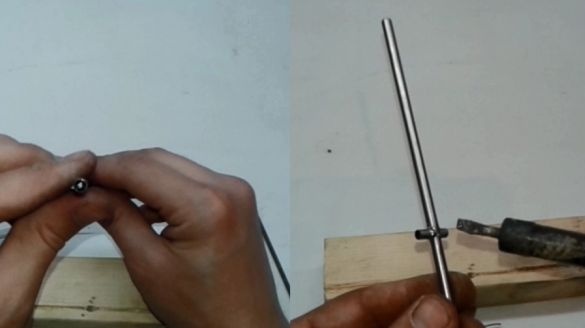

First, the author disassembles the antenna. Having cut off the antenna from both sides, it pulls out the tubes and gets 3 tubes of different lengths and diameters.

In the middle of the largest tube, a through hole is drilled with a diameter of 4 mm.

For the manufacture of a faucet, the author cuts a piece of 15 mm from the tube average in diameter. At a distance of 5mm from the edge, a 3mm hole is drilled.He puts a piece of tubule on a nail in an emphasis to a hat. Marks on the nail where the tube hole is located. Marks a cut line 4 mm below the tube. Drills a hole with a diameter of 2 mm in a nail. Cuts a nail along a previously drawn line.

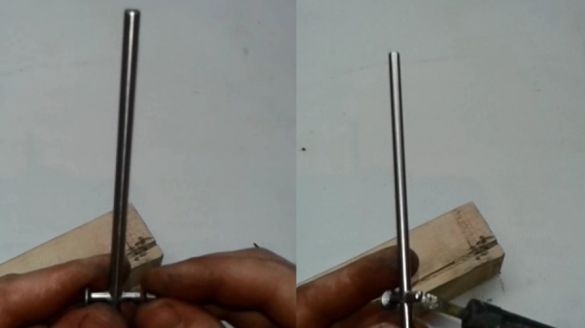

Inserts a tap into the hole drilled in a large tube. Aligning the holes in both tubes solders them.

That the nail would not jump out does a stop. Cutting off a piece of 4 mm from the middle tube puts it on a nail inserted into the tap. Solder the edge of the nail and the cut piece. It is necessary that the nail rotates in the faucet.

Further, in order not to break, the author inserts a piece of wire into the thinnest tube and bends it around the can forming a semicircle of 70-80 degrees.

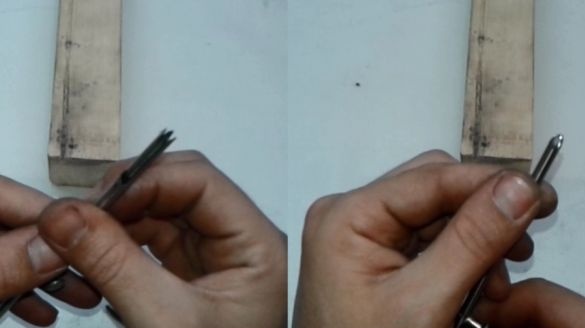

Makes a nozzle. Cuts off a head from a needle for balls. Solder the needle at an angle to the semicircular tube. This is done so that you can then insert the nozzle into a large tube.

Marks the hole on the tube with the tap where the nozzle will be inserted, given that the end of the nozzle should protrude a couple of millimeters from the tube, and the opposite end of the nozzle tube. Excess can be cut off.

Having made a hole (not through), the nozzle is inserted. If necessary, the edge of the tube can be cut.Incuts the edge of the tube into 6 parts and bends them inward.

Inserts the opposite end and solders both sides of the tube.

Next makes the burner head. Cutting off the 5mm key from the key, it expands the hole with a 5mm drill and puts it on the nozzle.

Makes fuel tank. He drills two 4mm cans into the lids - their holes are opposite each other. Inserts the middle tube into one of them so that it does not reach the bottom of the can by 1 cm. Having retreated from the lid, 2 cm cuts it off. Sawing off another 2.5 cm from the tube inserts it into the second hole in the lid. Solder the tube to the lid.

The tube from the compressor connects to the long tube of the tank, and the burner connects to the short one.

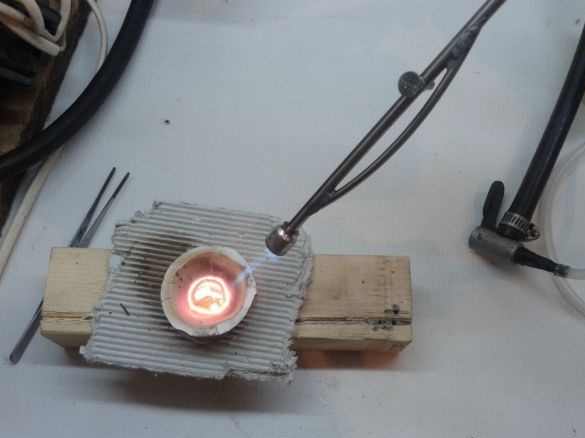

Pours gas into the tank and, following safety precautions, ignites the burner.

You can watch the video in more detail.