A long time ago, an old VAZ 32101 stood in the author’s courtyard. She stood and occupied places for a long time, while repairing this car would be too expensive and not advisable, but it’s a pity to dispose of. However, something still had to be done with her, since taking a place in the yard, having become even more unusable, was not at all what the author would like for this machine. Therefore, on its basis, he decided to make a tractor that would be useful in the household, while the task was to spend as little money as possible on additional parts, while collecting a decent tractor.

Thus, the author decided to proceed with the construction of the planned miracle machine. We recall once again that the task was not how to make a very good tractor and what details would be better to use, but how to assemble something useful from the available vases 32101, a limited number of parts and a budget.

The assembled tractor has the following dimensions: the length is approximately equal to 4 m 85 cm, and the width of the base is about 2 m 40 cm.

Materials, assemblies and parts that the author decided to use in the design of this tractor:

1) transfer box from the car Niva

2) front propeller shaft also from Niva

3) the main details from the vaz 2101

4) the fracture node was welded by the author independently

5) 1300 wheels

6) gearbox from vaz 2108

7) gearbox from UAZ

Now we will understand the scheme of the main constructions of this tractor, and also consider how the author built this device.

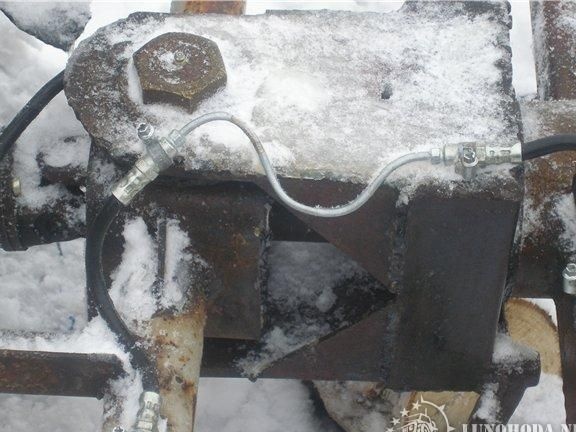

Consider in more detail the design of the fracture node of this all-terrain vehicle:

When assembling it, the author was guided by the prototype of an all-terrain vehicle at 2 gearboxes from ZAZ with the possibility of syringing, which I found on the forum in the completed projects of all-terrain vehicles. A link to the forum used by the author will be given at the end of this article.

in the first version of the assembly of the all-terrain vehicle, the author received a car very similar to an ordinary Niva, if you look at the transmission ratios.

Therefore, the question arose of a change in design, otherwise it will be impossible to put the planned 1300 on 500 wheels on the car, since it simply will not pull anything more than the tires from the "bull" R16.

Therefore, it was decided to install the gearbox from the VAZ 2108 so that there would be no complaints about the reliability of the systems of this all-terrain vehicle.

According to the assumptions made by the more experienced all-terrain vehicle builder at the forum, when using a gearbox from a VAZ 2108, a karakat with 1300 by 500 tires should be excellent in reliability and cross-country ability, while the bridge structure will withstand the load.

Therefore, the author began to look for the possibility of installing a gearbox from a VAZ 2108 to an engine from a VAZ 2101, since buying an engine from a VAZ 2108 was not part of the planned budget for this car.

In order to understand how to combine a similar design together, the author decided to study the location of the mounts, as well as all possible practical ways to implement such solutions. The gearbox from the VAZ 2108 has 5 mounting holes, if you look at the box from the engine side, then there are 2 mounting holes on the right, internal for 083, and external for 01-06, and for injection engines, the ignition module is also attached to it. It sounds rather complicated, therefore, for a better understanding, photos of the implementation of this method of fastening will be given below:

While the main wheels were not delivered, the author conducted some tests on conventional ones. As a result, it was noticed that the repetition angle is small and comparable to the Lada, but only on a clean road. In the snow, for example, 15-10 cm, the light butt in the turn weaves like a broom and turns disgustingly.

Therefore, waiting for the delivery of large wheels, the author came to grips with their installation on the tractor. The cameras turned out to be inconsistent, which consists in the fact that due to the large weight of the front of the all-terrain vehicle they are turned out of the chains, so the author began to look for other solutions for the shoes of his car.

He saw the solution either in the dregs or in the tires from Shain.

Meanwhile all-terrain vehicle began to acquire a lining:

A dump bucket was installed on the all-terrain vehicle, which is capable of lifting 30 cm. Its fastening is based on two bolts of m 12. Also, the bucket system can be rotated left and right thanks to two loops f 30. Installation and configuration are made in just a few minutes, for using a similar simplified bucket control scheme.

The author also considered and, if possible, made modifications to the dump truck. The possibility of shortening the frame in such a way that it ends immediately behind the bridge, as well as the cross member on which the hinge of the body was mounted, was considered. Hinges are installed in the center of gravity of the body or with a slight deviation back. Such a scheme simplifies unloading, that is, when releasing the body mount, just push it slightly and it will tip over itself due to a shift in the center of weight. It was in this way that the author originally wanted to do, but changed his mind because the angle of elevation was not too large, and shifting the bridge and sawing cardans was too troublesome.

The author also considered the possibility of strengthening the fracture site by altering the half-frames with a trapezoid. Since the transverse beam works on twisting, the shorter and stiffer the better. In addition, with this approach, it is possible to increase the reliability of the design of the unit while not weighing it down.

This is how an all-terrain vehicle changed into new wheels looks like:

In the course of testing, it turned out that for clearing snow, you can’t imagine anything better than chains for this all-terrain vehicle.

This is how the all-terrain vehicle looks after all the upgrades:

For several years of operation, problems with the fracture unit did not arise, despite the fact that the reducer from the field vomited 2 times, after which it was replaced by an UAZ one.