Everyone who has car, knows that replacing tires is a must and a must. After re-shoeing, unnecessary “wheels” remain, which can either be thrown out or made of them something interesting and original. For example, a coffee table.

We take the usual used rubber remaining after replacing with a new one. Choose the least affected during the ride. We wash it and clean it so that the tire gets its original matte black color.

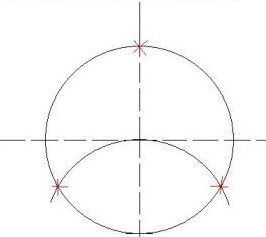

Next, mark the tire into three parts, and in each mark we drill a hole with a diameter of 10 mm for the studs, which will give the cylinder some rigidity. The holes for them are drilled in the side.

We insert the studs into the resulting holes and fix them. Now, with the help of a crown, we drill three more holes of a larger diameter under the legs.

Since the studs are not enough to give the wheel good rigidity, we cut out blanks from 16 mm plywood that will repeat the contour of the inner space of the tire, except for the lower part. They remain flat. The pattern is made of cardboard and transferred to plywood.

Parts should be 9 pieces, 3 on each side.

Details are cut out el. a jigsaw and 3 pieces are glued together. For better fixation, parts can also be fastened with self-tapping screws.

An insert will be installed in the lower part of the tire, which will serve not only to increase rigidity, but also a platform for attaching the legs. We take a regular board, using a cardboard template on its end part we draw a rounding. With the help of a planer we give the workpiece the look we need.

We take our pieces glued together in 3 pieces and with the help of a saw we make a groove for the studs in them. Grind and varnish.

Prepare the legs. For this, a normal shovel handle is suitable. In the middle of each workpiece, a hole is drilled for self-tapping screws. If there is an opportunity or a lathe, the legs can be made carved and tapered.

Now we fasten the legs to the lower platform, and lower them through the hole. After this, stiffeners are installed. Outside we fasten the tire to the platform.It is good to take genuine screws so that they additionally pass through the stiffeners.

From 6 mm plywood, cut a circle to the bottom of the table. We install metal inserts or large washers on the studs that will hold this plywood.

The table cover is made of 16 mm. plywood. We cut out the circle, grind it and cover it in several layers with furniture varnish. If a pile cover appears during painting, wait until it has completely dried and go over with a fine emery cloth. Then varnish again. Attach stops to the back of the countertop so that the countertop is positioned exactly in the center of the tire.

That's what happened and the end result. An interesting table with interior space for small items, magazines, etc.