Sandblasting machine - an indispensable thing in the garage. With it, it is convenient to clean old paint, rust and other types of pollution. Using sandblasting, you can quickly and efficiently clean the most inaccessible places. Another such device can be engraved on glass and other materials.

As a basis for homemade The author used a small compressor. Perhaps this is the most expensive part of homemade work, which will cost about 3,500 rubles. As for sand, the device works perfectly on the most ordinary building sand, which must be sifted through a fine sieve before refueling. If there is no desire to mess with the sand, then you can buy ready-made, especially for these purposes.

Of course, all work is carried out either in a special room or in the open air. You also need to take care of protective equipment. It is necessary to protect the respiratory system from dust, and you will also need protective glasses or a mask so that the sand does not get into the eyes. When working, there should not be open skin areas, as breaking sand grains can dig into the code or leave a wound.

In the photo you can see how the homemade product looks. As you can see, a regular bottle was used as a filling tank. And homemade looks like a spray gun.

Materials and tools for homemade:

- small compressor:

- a plastic bottle with a volume of 1.5-2 liters;

- water ball valve;

- lathe;

- ceramic nozzle (used in dental sandblasting machines);

- air hose, wrenches and other items.

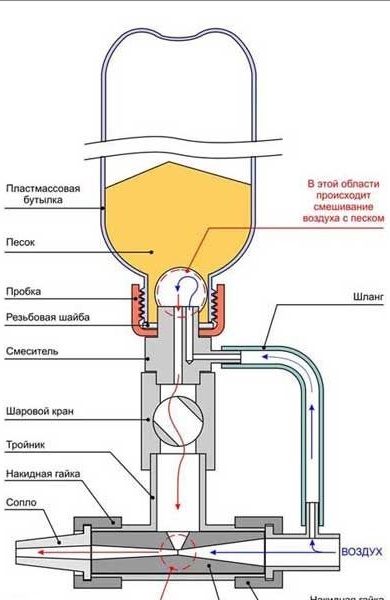

Step one. How the device works

How homemade work can be seen in the photo. As soon as the master pulls the trigger, air under pressure passes into the gun channel, and then enters the bottle, creating high pressure in it. There is a special liner in the bottle, thanks to which sand is mixed with air. A special valve is provided to regulate the flow of the air-sand mixture. Well, then the mixture passes through a ceramic nozzle. Here, in fact, on this principle this sandblast works, and many others.

It should be noted that the nozzle must be ceramic, these are exactly the ones used in sandblasting machines. First, the author decided to make a nozzle himself by drilling a hole with a diameter of 2.5 mm in steel. However, after fifteen minutes, the hole doubled and this led to a sharp decrease in homemade productivity.

Step Two Device elements

The gun is made of a plastic bottle (sand is charged here), as well as a ball-type water tap. Still needed a tee and a crane from the spray gun. In a homemade product there are such elements that are machined on a lathe.

In the homemade product there is such an element as an insert. This is a kind of injector with conical holes, at the point of convergence the air pressure drops, due to this the air from the bottle rushes to this place with the sand. Sand consumption is regulated by a crane.

You should also pay attention to the mixer; a bottle cap is screwed to it with a threaded washer. The author tried to make such a cork out of steel, but it did not work out, as a result, it will be necessary to change worn parts from time to time.

Step Three Sandblasting Machine Operation

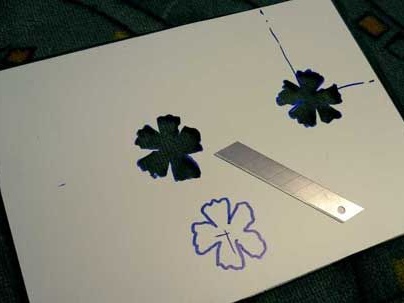

The peculiarity of this device is that it can be used to make glass engraving. To do this, the glass must first be sealed with a self-adhesive film. Next, you will need to cut out the pattern, in other ways it can be cut out on the film even before gluing. Well, then process the glass with a sandblast. What eventually happened can be seen in the photo.

Such engraving on the glass is well illuminated using LEDs. With this sand treatment, the drawing is much clearer than when working with a dremel. To make the engraving deeper, you just need to pass sandblasting more often in one place.

It is also convenient to make holes in the glass with the help of such homemade products, they turn out to be very even. To do this, you need to drill a hole in a metal plate, and then attach the plate to the glass and sand over the entire surface of the hole. Depending on the thickness of the glass, it takes about 3-4 minutes to make a hole and one bottle of sand. You can also make holes not only round, but, for example, square.

The only drawback of homemade work is that you often need to pour air into the bottle, but homemade work is not intended for work on an industrial scale. Still need to change worn out elements from time to time. By the way, sand, which is refueled into the device, can be used a second time, but, of course, it will need to be sieved.