For those who have country the plot, and especially the greenhouse, will be simply irreplaceable to make just such homemade. This device is designed to automatically irrigate the site at a given time, and it can be connected to any crane with any throughput. This provides significant advantages over factory timers.

The author uses drip irrigation, for which water comes from a large tank. The purchased timer was never able to provide a sufficient amount of water to the irrigation system, since it is designed for high pressure.

Materials and tools for homemade:

- ordinary wall clocks (arrow);

- reed switches and magnets to them (total reed switch 3 and 2 magnets);

- three batteries;

- 2 buttons are required to create manual control (if necessary);

- transistor IRLML6404 (or other P-channel logic) - if the rain sensor is not used, you can not put it;

- three output mechanical crane CWX-15Q CR02 (or another);

- wires, soldering iron, glue and more.

Water timer manufacturing process:

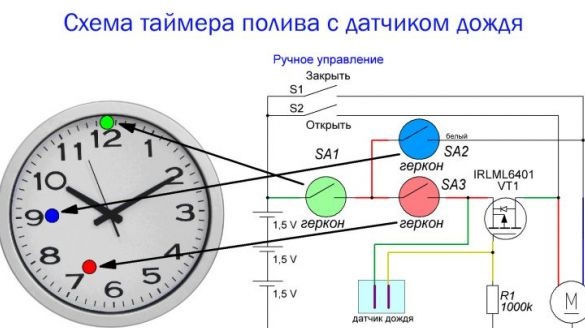

Step one. Scheme and principle of operation

The device works very simply. On the hands of the clock are magnets that interact with the reed switches, closing, then opening the contacts. In total, three pieces are used for the reed switch, so that you can set the timer by minutes and hours. Well, then everything is connected as in the diagram.

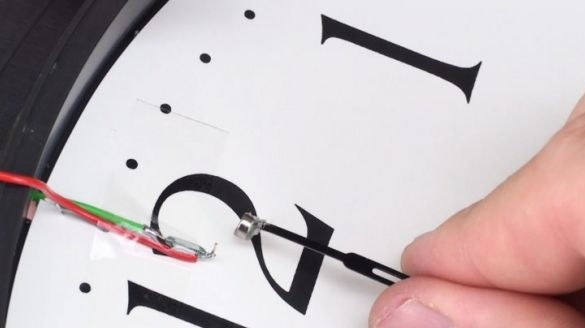

Step Two Connection of reed switches and electrovalve

On the hour and minute hands you need to glue small neodymium magnets. Reed switches are installed on the dial itself, they can also be glued. When the magnet approaches the reed switch, the contacts in the reed switch will be closed, and then the power will be supplied to the control transistors.

As an example, the author's reed switches are installed on the numbers 7, 9 and 12 hours. Provided that if the minute hand is opposite the number 12, and the hour hand opposite the number 7 hours, the transistor will receive voltage. Well, then the transistor opens and passes current to the solenoid valve, thereby opening it. This is provided that the rain sensor has not detected high humidity. If it rains, the valve will not open.

When the arrows stand at the numbers 9 and 12, the electric valve will close and watering will end.

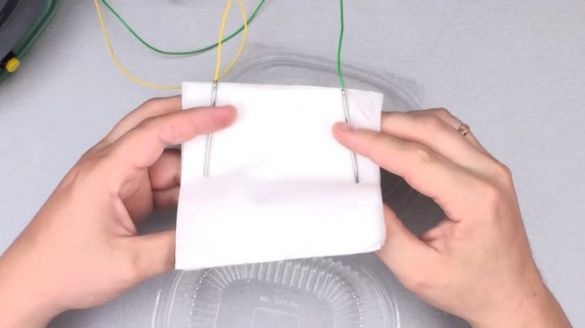

Step Three How to make a rain sensor

The rain sensor, if necessary, is very simple to make. It is very primitive and is assembled from two electrodes, a napkin and a pinch of salt.When it rains, the wipe gets wet, the contacts close and the transistor closes. Then, when the cloth dries in the sun, the transistor will open again.

To learn more about how the device works, see the video: