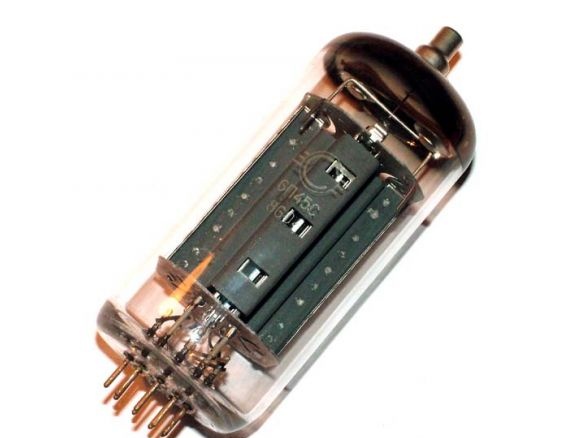

As a heater for a low-voltage electric soldering iron, you can use the filament of a previously used medium-power radio tube, for example, 6n5s

or 6p45s.

The coating of the cathode heater itself isolates (electrically) it from the tip (copper rod) of the electric soldering iron.

A copper rod with a diameter of 5 mm or more is drilled in the end along the diameter of the heater used so that reliable thermal contact is created between the tip of the electric soldering iron and the heating element. The soldering iron tip is fixed in a metal tube with a screw. The conclusions of the heating element are connected to the power wires and isolated from each other and from the walls of the metal tube with a thin asbestos thread and heat-resistant paste prepared do it yourself.

The power supply voltage of the electric soldering iron is 6.3 V variable, which can be removed from the filament windings of any transformers or use a separate low-power transformer.

It takes a little longer to heat such an electric soldering iron than to heat a conventional standard electric soldering iron and is determined by the mass of the sting and the power of the filament of the radio tube.

Heat-resistant paste is prepared as follows: talc is mixed

or baby powder

with silicate glue

to a sour cream - like state.