Like most fans to listen to music in car, the author had a desire to put a subwoofer in his car. An ordinary box-shaped subwoofer occupies a quarter of Oda’s small trunk, which the author did not like at all. That is why he decided to make a subwoofer in a stealth enclosure.

Materials:

- fiberglass T-13

- epoxy adhesive

- dynamic head Hertz DS250

- fiberboard

- glue moment

- masking and packing tape

- wire

A detailed process for creating a stealth subwoofer.

The author decided to install a subwoofer in the left luggage compartment. Below you can see the photo of the trunk of the author’s car.

Having collected all the necessary materials, the author proceeded to create a subwoofer enclosure. Since the main material for the hull will be fiberglass, the author decided to use masking and packaging tape to create a separation layer in the trunk. This will prevent the subwoofer from sticking to the carpet or plastic trunk panels.

Further, the author proceeded to gluing the case. To do this, he impregnated narrow strips of fiberglass in epoxy. It is best, according to the author, to impregnate on a sheet of glass. The composition of the impregnating glue, the author chose this: one part of the hardener accounts for 10 parts of epoxy resin. To make it easier to breed, the author used any plastic containers at hand.

On the second day of sticking, the author realized how time-consuming the process was and decided to simplify the assembly of the subwoofer a little. In order to save material, and most importantly the assembly time, the author decided to make a part of the subwoofer casing located behind the suspension strut from pieces of fiberboard. He decided to temporarily tighten these pieces with a wire between himself for fixing.

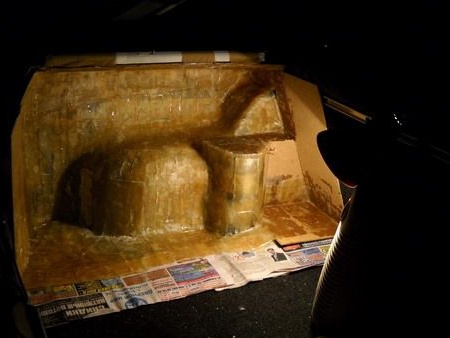

Working about 4-5 hours in two days, the author received the following result, which you can see in the picture. For all this, three packs of 280 g epoxy glue were used. each one. In addition, gluing took 2-3 square meters. fiberglass meter t-13

On the 3rd and fourth days, the author proceeded to pasting the upper part of the subwoofer enclosure. After gluing the upper part, the author removed some of the wire and engaged in gluing the joints of the pieces of fiberboard. To save time and effort, the author also decided to make the right side of the subwoofer enclosure, which will be adjacent to the seat, from fiberboard, in particular, this was facilitated by a flat surface. The work dragged on and some of the author even had to do it in the light of a desk lamp.

It was the fifth day of assembling the subwoofer, and the author glued the left side, while increasing the thickness of the lower part of the subwoofer. What took a couple more packs of glue.

By the end of the sixth day, the author began to extract the resulting body from the trunk niche. Due to the fact that he previously used scotch tape as a separation layer, the undocking of the subwoofer case occurred as successfully as possible, without breakdowns. Having consumed another pack of glue, the author glued to the end part of the buffer where the fiberboard was used.

A week passed on the subwoofer in the car. Having drawn the approximate dimensions of the body volume by pouring it with water, the author received a volume of 20 liters. However, the water did not cover the half-cylinder; therefore, the total volume of the subwoofer body should be estimated at about 30 liters or even more.

Since the case was almost ready, the author began to search electronic stuffing for your subwoofer. The Hertz DS250 dynamic head was chosen as the main speaker, since, according to the recommendation of the "car audio" magazine, a 23-28 liter body should fit perfectly for this speaker.

The second week of work began, the author aligned the edges of the fiberglass subwoofer casing and proceeded to create the front panel. The front panel of the subwoofer is made of fiberboard. The author decided to fix the lower part of the panel with a wire, and the front part curved above the middle of the hole, which is intended for the speaker.

So that part of the front panel does not bend to the bottom, the author decided to put another piece of fiberboard to the middle of the hole, and also made some kind of backups.

Next, you can see in the photos what the upper and lower parts of the front panel of the subwoofer look like. As you can see, the author also decided to fix the upper part with wire. To gain sufficient thickness of the front panel and give it the necessary strength, the author used the remaining pieces of fiberglass, which was glued according to the same scheme with epoxy resin.

In order to securely fix the speaker, the author made a semblance of a support ring from several layers of chipboard. The chipboard was fastened with self-tapping screws and glued for strength. The ninth day of work on the subwoofer in the trunk was coming to an end.

To avoid gaps between the ring and the front of the subwoofer panel, the author additionally glued everything with several layers of fiberglass. In addition, this increased the strength of the case.

On the tenth day, the author measured the final volume of the case, which turned out to be just about 27 liters, which perfectly fits the selected speaker. After the ordered Hertz DS250 speaker was delivered to the author, he continued to work on a subwoofer project.

After installing the speaker, the author proceeded to the final stage: pasting the subwoofer body with a carpet. It took 1 m of carpet and 3 tubes of glue of the moment.

After that, the author cut a small hole in the subwoofer body, or rather, in its end face adjacent to the seat. A screw terminal was installed in this hole, allowing you to quickly connect or disconnect the subwoofer as needed.

The result was a great subwoofer that pleases the author with quality music, and the boot volume has become much freer than it was when using the standard subwoofer case.