With high-quality brazing, a prerequisite is the use of a flux, which effectively removes oxides from the surface of the tracks and leads of the components, reduces the surface tension, and generally improves the solder flow. For some work, thick solder paste, such as RMA-223, or in our case a copy of the widely known American flux from amtech, is best suited. It is perfect for reballing large microcircuits, their dismantling and installation using a soldering hair dryer.

I want to note that it has an unpleasant odor and can be hazardous to health, so it is recommended that you use a special smoke trap or even a fan when working with the Chinese RMA-223 simulation.

After soldering, this solder flux is very easily washed off with standard alcohol, acetone or any other dehydrator using a brush, and does not freeze like any pine rosin. Since the RMA-223 is non-aggressive and does not conduct electric current, theoretically, with its residues on the board electronic device it should work fine.

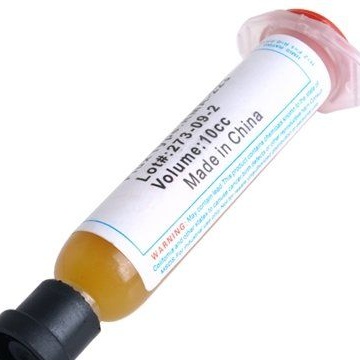

In such a syringe is placed 20 grams of flux. It has good viscosity, has a translucent yellowish color, sticky, evenly distributes the temperature when soldering and does not cause corrosion over time. In general, for not very important soldering work, it can be used.

Cost: ~ 162