Proper preparation of the base before laying the laminate is one of the main conditions for the durability of the coating. If the laminate is laid on an uneven base, the pressure on the lamellas will be uneven. This will quickly affect the state of the joints: in a short time they will begin to diverge (even with high-quality locks). The surface of the floor will not be even; when walking, it will creak.

Therefore, before laying the laminate, make sure that the surface is prepared properly. The main requirement for the base is a height difference of not more than 2-2.5 mm per linear meter. Its quality is checked using a two-meter rule line, which is laid in different directions. Roughness of the surface, not exceeding 1-1.5 mm per linear meter, does not need additional alignment. It is eliminated by a good substrate under the laminate. If the roughness is larger, you should not eliminate it with several layers of the substrate - this will not help.

There are several ways to level the base under the laminate.

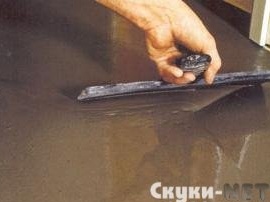

Leveling mixtures for this purpose go on sale in dry form, diluted with water according to the instructions.

Usually two types of leveling mixtures are used. One is for rough leveling, it forms the main thickness of the screed. These compositions include large fractions, which makes it possible to apply them in a thick layer. They allow you to align differences from 1 to 7 cm.

As the initial layer, concrete preparation is usually used. It is very important to withstand the process technology - before applying the finish layer, the concrete screed should be kept until final drying - at least 25-28 days. Its humidity should decrease to 4%. Laying floors on a dry basis leads to trouble - subsequently, the laminate is deformed due to moisture saturation. You can check the humidity with a plastic film, which is laid on the site and pressed along the perimeter. If condensation forms under the film within 2-3 days, drying should be continued.

The second type of mixture is for finishing (finishing), it consists of smaller fractions. It is applied over the base layer, resulting in a flat surface. Both foreign and domestic manufacturers offer an extensive range of such compositions.

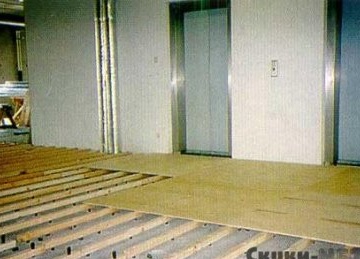

Another way of leveling the base is the device of raised floors - adjustable floors on the logs. In this case, racks with bolts are mounted on a rigid base, on which wooden logs are fixed. Leveling the base is achieved by rotating lags.

The advantage of this method is the absence of the need for prolonged drying, wet processes, dirt, dust, which are inevitable when laying self-leveling mixtures. Moreover, insulation and flooring make the floor warmer.

The disadvantage of this method is the high floor level, which is especially true in the case of low ceilings. But when using lags, you can mask the wiring not in the walls, but under the floor - this will be cheaper.

A similar way is to align the base with plywood. The height of the floor while not more than 3-4 cm. Plywood sheets are rigidly fixed on the base and aligned with threaded bushings. The second is laid on the first layer of plywood - it overlaps the seams of the first and is fixed with screws.