The device for spot welding is a useful and necessary device. Using such a device, it is possible to weld thin metal, which is problematic when using conventional welding. You can also weld various metal alloys.

Tools and materials.

Microwave;

Stranded copper wire;

Copper rod;

Fiberboard;

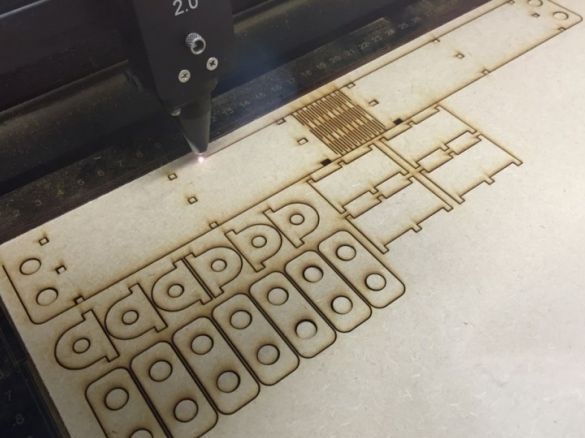

Lathe;

Laser cutter;

Vise

Wrenches, screwdrivers.

Step 1.

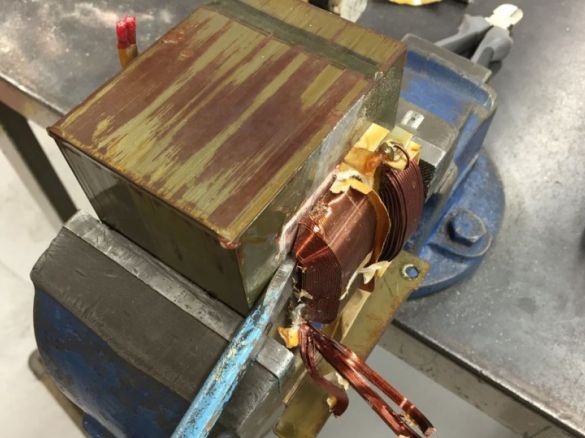

Caution: hazardous voltages may remain on electrical parts. First, the author disassembles the microwave oven and removes the transformer from it. It untwists the fastening of the case, removes it. To remove the voltage, short-circuit the capacitor with a screwdriver with an insulated handle. Unscrewing the bolts, removes the transformer. For the welding machine, limit switches are also needed. Their author also takes off the microwave.

Step 2

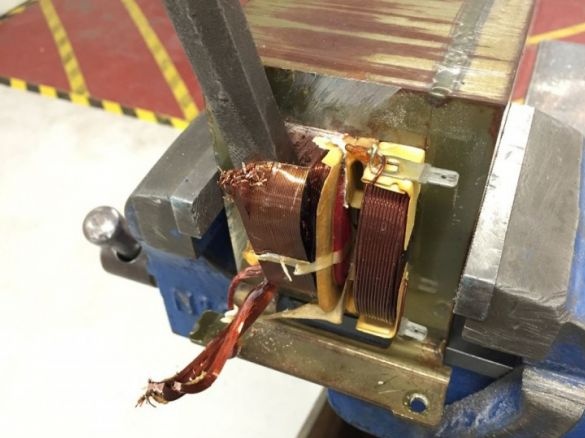

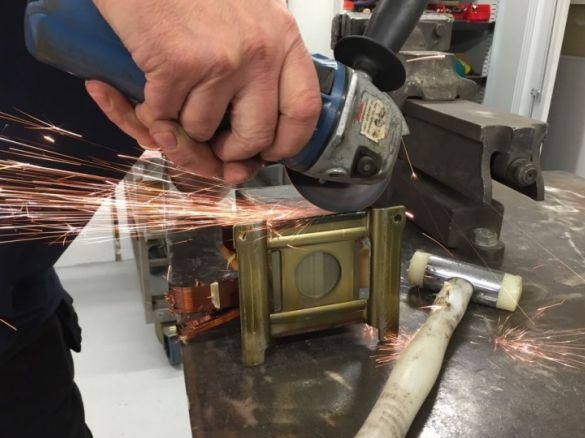

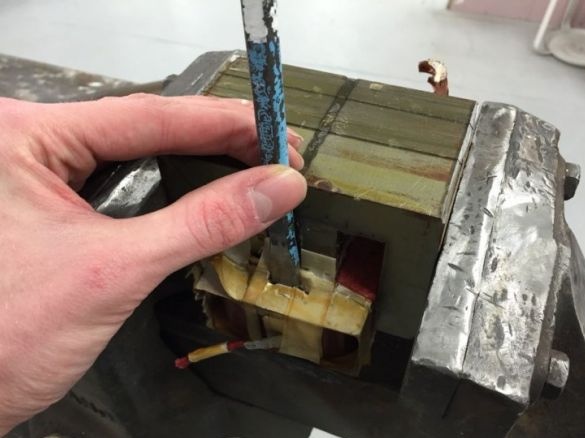

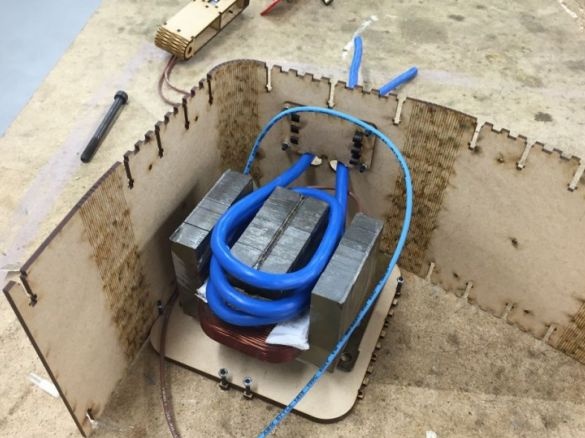

In order to increase the current strength, you need to remove the secondary winding of the transformer and replace it with another. Clamping the transformer in a vice, cuts off the magnetic circuit. Carefully, so as not to damage the primary winding, dismantle the secondary winding of the transformer.

Step 3

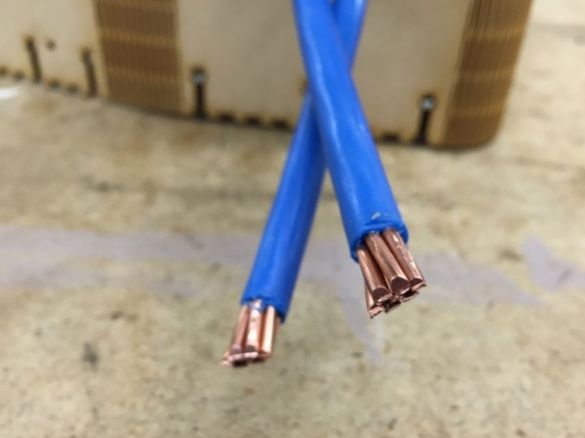

Between the primary and secondary windings, two shunts are installed on each side. A thick stranded copper wire is wound in place of the remote winding. Makes two turns. According to the author, a thick cable allowed to reduce the number of turns, and its insulation is strong enough not to melt.

Step 4

Installs the upper part of the magnetic circuit and welds it.

Step 5

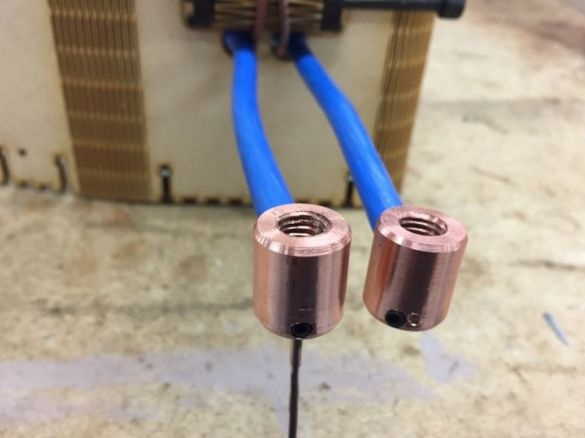

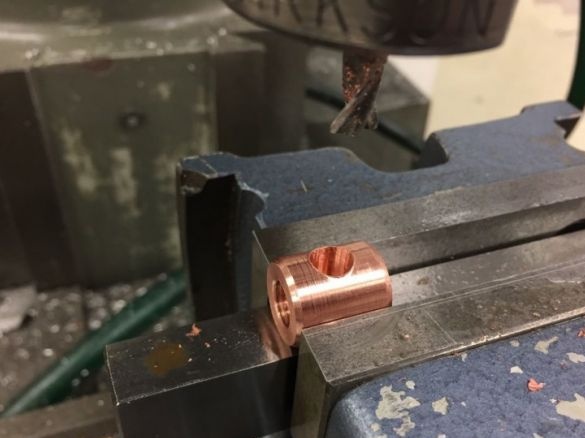

On a lathe, grinds two bushings from a copper rod. Threads them. On the one hand, electrodes will be screwed into the bushings, on the other, the ends of the cable are attached.

Step 6

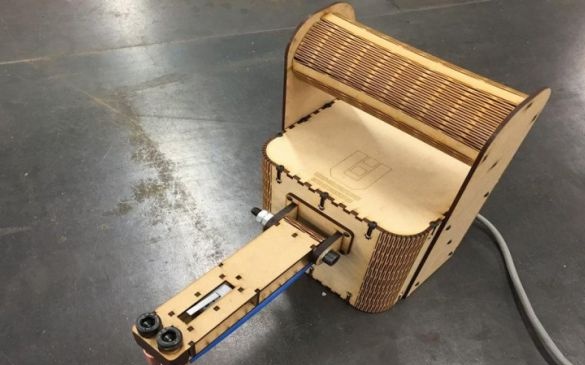

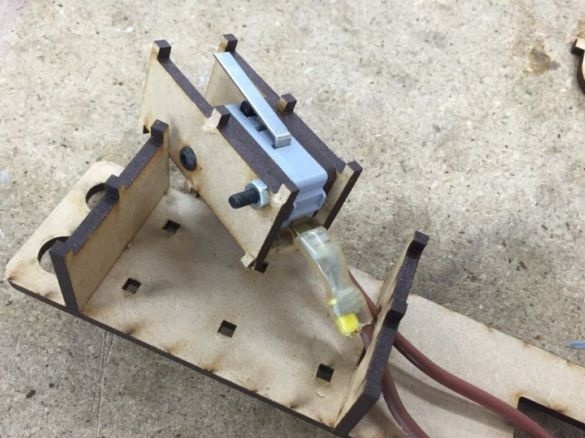

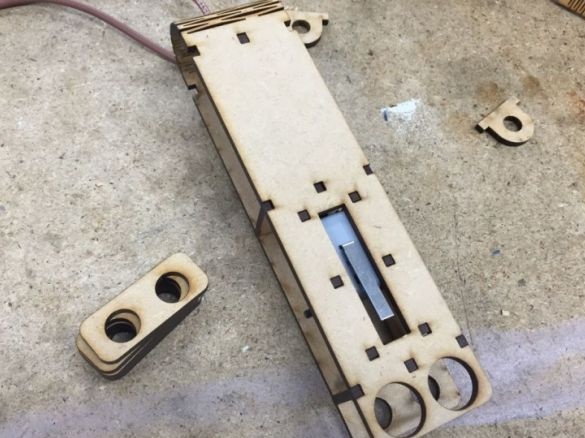

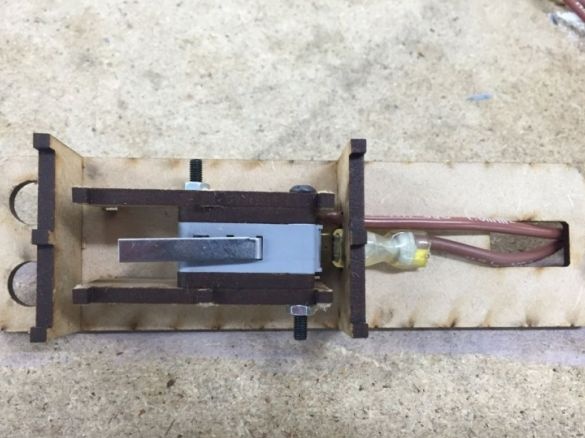

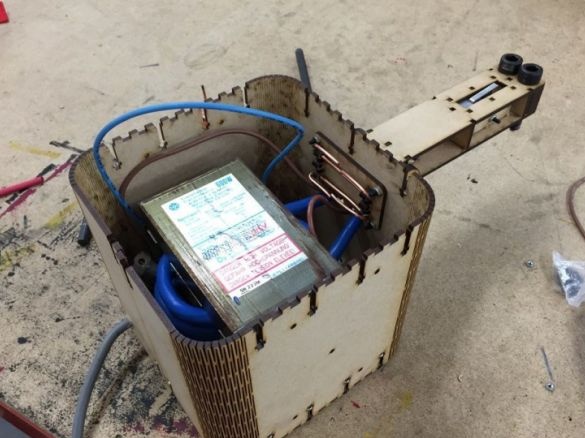

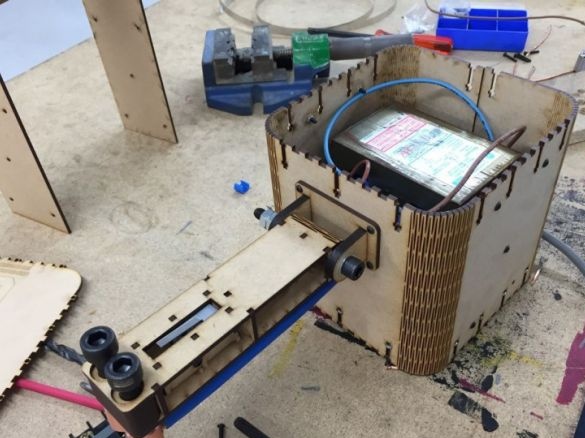

In order to make the holder and the case, the author developed their project in a special program. Then he cut out parts of the fiberboard with a laser cutter. Since the author needs the apparatus to weld nickel plates to the batteries, the electrodes in the welding machine will be located in the same plane.He assembled the holder, installed a switch on it. The switch will be powered on one of the power wires.

Step 7

Assembles the body. Installs the holder. The holder moves in a vertical plane. It is attached to the body with a bolt, the axis of which will move. Connects the cable to the holder and switch. Installs electrodes.

The whole device is ready. It remains only to try the device in operation.