Tools and materials:

-Electric motor;

-Board;

-Sheet metal;

-Bolts, nuts, angles;

-Drill;

-Screwdriver;

-Soldering iron;

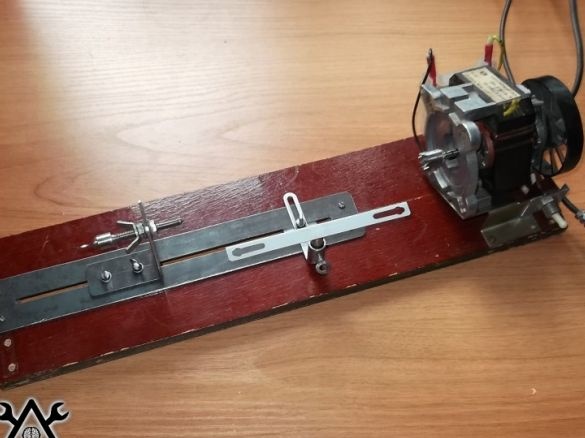

First, the author in the board, which will serve as a bed, makes a cut in the middle, two-thirds of the length.

Cut out the overlay cutout from metal.

Screws the pad to the bed.

Secures the electric motor. The engine should be on the same axial with a slot.

I made a headstock from a tube. Cut off a piece of the tube. He made a cut in the tube in the form of a crown. Soldered the crown to the nut. Screwed the manufactured headstock to the engine shaft.

He made a handyman and set it on the bed.

Made a tailstock. I bent a corner from metal. Drilled a hole at the height of the headstock. Soldered the nut. Screwed a long bolt with a pointed end into the nut. The headstock will be fixed with a counter nut. He drills two holes in the lower part of the corner and fastens the headstock to the bed.

The lathe is ready, you can start processing wooden products.

The machine in operation can be seen in the video.