On sites homemade A great many soldering iron stands. The author of the homemade product made this stand based on his previous experience. A distinctive feature of the stand is its built-in power regulator, which allows you to adjust the heating temperature of the soldering iron.

Tools and materials:

-Radio components;

- chipboard;

-Plastic;

-Tin;

-Fasteners;

-Clamp;

-Metal sponge;

-Rubber;

-Glue;

-Drill;

Cutter;

-Soldering iron;

-Hair dryer;

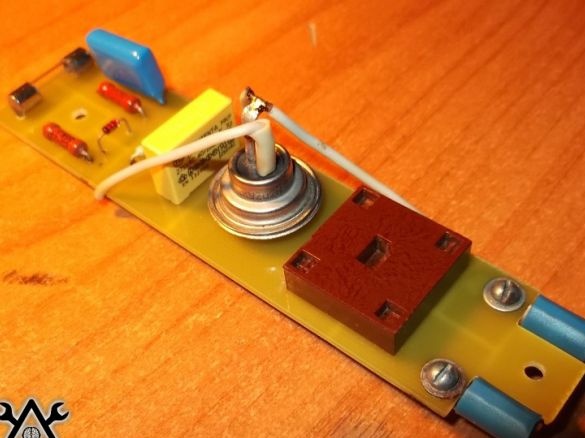

To begin with, the author assembled a power adjustment board according to the scheme.

I cut out a blank of the board case from plastic. He bent the plastic using a building hair dryer.

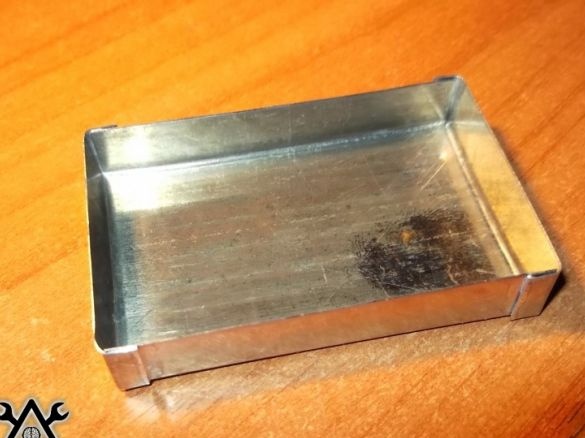

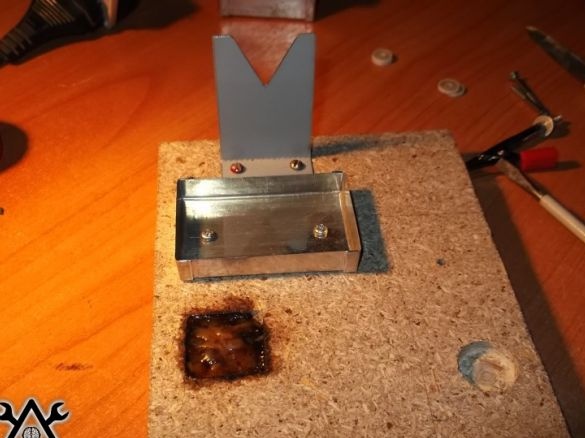

I cut out a box from tin and soldered corners in it.

Made another box for a metal brush. Using a brush, the author cleans the soldering iron tip.

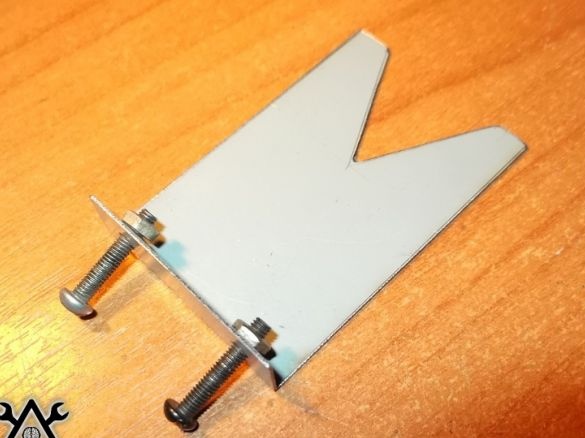

Cut out an emphasis for a soldering iron.

I soldered a bolt to the clamp. He will play the role of a "third hand."

I cut the base out of chipboard.

With the help of a cutter, he made a notch.

He put rosin in the recess and melted it with a construction hairdryer.

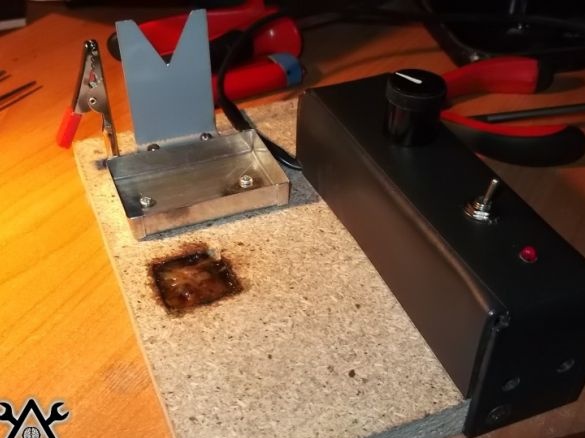

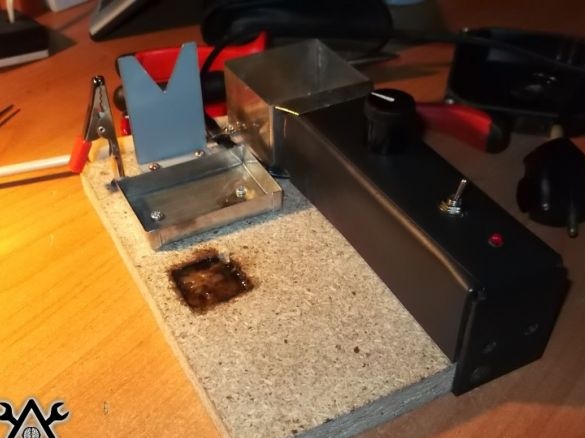

Secured a metal box stand and clamp.

Screwed the board.

Replaced the board body.

Screwed the box for storing small things and an iron brush.

Cut out anti-slip feet from rubber. I glued them on the back of the stand.

I printed, cut and pasted the inscriptions on the power adjustment board.

Soldering iron stand ready.