“The house begins with a gate ...” - a statement that is difficult to argue with. But what gate can exist without a good, strong fence nearby? Today we will analyze how to get this fence and get it - inexpensively and not for one year.

So, the fence for the infield. Among the whole variety of materials available today, one of the first positions, of course, is corrugated board. The fence, built from corrugated board, is not only easy to care for, convenient and durable, but also thanks to a variety of color options, it can decorate your site, adding a certain completeness and beauty to it.

Having decided on the material, it's time to do the preparatory work. To do this, you need to prepare the tools we need and calculate how much corrugated board and supplies we need.

In addition, already at this stage it is necessary to prepare the area of the site for the installation of the fence - to level the surface and remove all objects that interfere with the future fence.

Having completed the preparatory work, it is necessary to start marking the territory on which the fence will be installed. To do this, it is necessary to pull and fix the cord between the extreme points of the future fence, aligning it with a water or ordinary level.

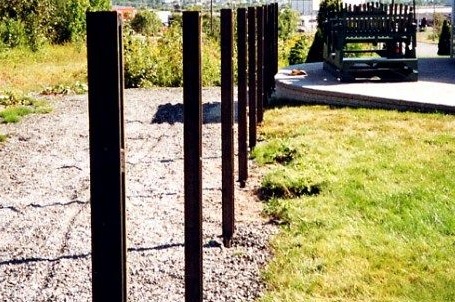

A few words about choosing columns for the future fence. Such poles can be made of metal pipes, wooden beams or a square metal profile. Remember that when choosing wooden bars as the material for the columns, it should be understood that such material loses to the metal in durability and requires special processing before installation. In the case of using metal as a material for the columns, it must also be treated with a primer as well as wooden beams in order to prevent rust after installation of the fence.

We proceed to digging holes under the pillars for the fence. The ideal tool for this is a special drill, with the help of which the necessary number of holes should be made with a depth of the order of seventy to eighty centimeters each. However, if you do not have a drill, do not despair, because you can dig holes with an ordinary shovel.

In the prepared pits we install poles.To do this, we expose them vertically, checking their location with the help of the building level, check the correct position of the posts along the string stretched in advance between the extreme posts, and fill the pits with large stones, pouring these stones with concrete solution. Recall that the concrete mortar is prepared as follows: sand, small stones (gravel) and cement are taken in a ratio of 3 to 4 to 1 and diluted with water until a homogeneous mass is obtained.

Having installed and filled with a solution of support for the fence, you should wait for the concrete to solidify completely, which, as a rule, occurs after two to three days.

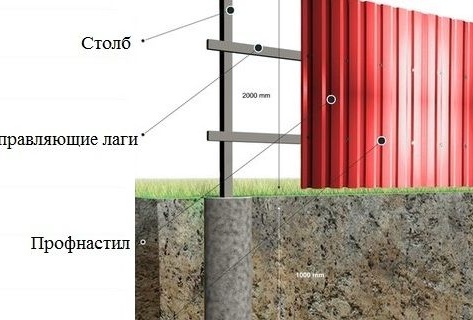

After a few days, when the poles are completely ready, you should begin to manufacture crossbars (the so-called "lag") for your fence. A few words about the methods of their fastening: welding is the best, however, if you don’t have the opportunity to weld the lags, do not worry, because the lags are easily attached to the fence with ordinary bolts.

The most suitable material for logs are metal corners or square pipes of a small section. When calculating the amount of material required for the cross members, it should be remembered that for a fence with a two-meter height, at least two rows of lags are necessary. In addition, pay attention to the fact that after the final installation of all elements of the fence frame, it must be primed or painted to prevent rust in the future.

Having made the frame of the fence, we set about installing corrugated sheets. In this case, special self-tapping screws that are screwed to the fence with an electric drill with the appropriate bat or a screwdriver will be the ideal fixing material.

The location of the sheets relative to each other must be checked with a cord tensioned at the level; the same cord must be tensioned when screwing the sheets so that the screws are fastened in one line, with the fastening step through one wave, in its inner part.

Remember that when working with corrugated board it is necessary to use tight gauntlets to avoid injuries and cuts that easily appear from contacts with the sharp edge of the sheets.

This completes the construction of the fence - the fence is completely ready and will protect your yard from unwanted guests and prying eyes for more than one year.