Damascus steel has been known since ancient times. They make it by repeatedly reforging various grades of steel. At the blacksmithing exhibition, the author acquired Damascus steel plates. The next step was the manufacture of a blank from a knife.

Tools and materials:

- Damascus steel plate;

-Tape grinding machine;

-Birch cut;

-Linseed oil;

-Vacuum;

- Brass bar;

Epoxy resin;

-Threads;

-Super glue;

- Danish oil;

-Slice of bog oak;

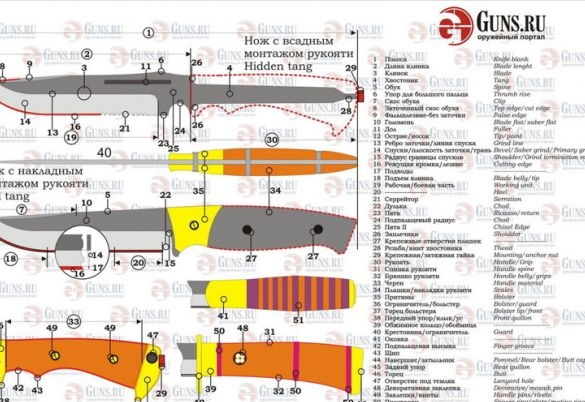

For a sample, the author took such a drawing of a knife.

Step 1: Stripping the plate

On a belt grinder, he cleaned the workpiece. He removed a layer of metal to reduce the thickness of the knife.

Step 2: shaping the cutting edge

Removes metal on descents forming a cutting edge.

At the end of the knife forms a curved descent. Stacks metal from the side of the guard.

Step 3: Blank for handle

The author made a knife handle from birch. I saw the birch boil in a salt solution. In order to emphasize the structure of the tree, willow branches were added to the solution during cooking.

I polished a wooden blank.

Sawed a plate from a tree. I placed the bar in the vacuum box with linseed oil. After the evacuation process, removes the plate and dries. According to the author, refined oil dries twenty-one days, and not refined three months.

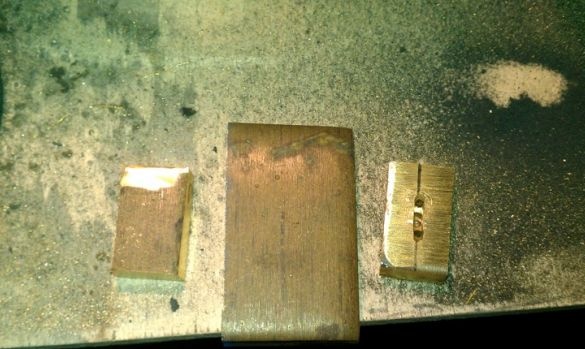

Step 4: Making the Finger Rest

The author made an emphasis from a bar of brass. Sawed off the right bar. In the middle I drilled holes. I made a slot connecting the holes. polished the emphasis.

Step 5: knife assembly

Drills a hole for a knife shank in a wooden plate. She puts a finger on the knife, then a plate of stained oak. Sets the handle blank on the shank. To fix the details among themselves, the author used epoxy resin. During the hardening of the resin, the parts were fixed with a thread.

After the epoxy hardens, a brass heel is glued to the tip of the handle. Between the handle and the heel I glued an insert of stained oak.

Step 6: Finalizing the handle

Processes the handle, forming a subdigital notch.

Grinds the handle with sandpaper. Gradually reduces paper grain from 40 to 2500.

After polishing, the handle is coated with Danish oil in three layers. Goi paste rubs the brass parts to shine.

Damascus steel knife and birch handle are ready.