Spindles and spinning wheels are one of the ancient tools for women to work.

The work of weavers and spins has long been revered by any nation; and the shape of spinning wheels and the methods of decorating them have been perfected for centuries.

Russian spinning wheels consisted of struts in the form of blades, ridges or forks, fixed at right angles in the base stands, on which the strands sat.

In the old days, girls began to work behind the spinning wheel for about eight years. They should have strained so many strands to be enough for a dowry. Often spun at a fun meeting of rural youth - gatherings

and in their homes.

After marriage, women were spun only in their free time, in fits and starts.

Where spinning was a trade, women spent all their young years behind the wheel.

Spinning wheels were wedding gifts of grooms for brides. Often spinning wheels were given for good memory from fathers to daughters, husbands to spouses. Therefore, such important things in peasant life were decorated with special care and diligence. Beautiful spinning wheels - gifts were kept in families carefully, literally, for generations.

In this article, I’ll tell you how I made an existing electric spinning wheel with retro elements.

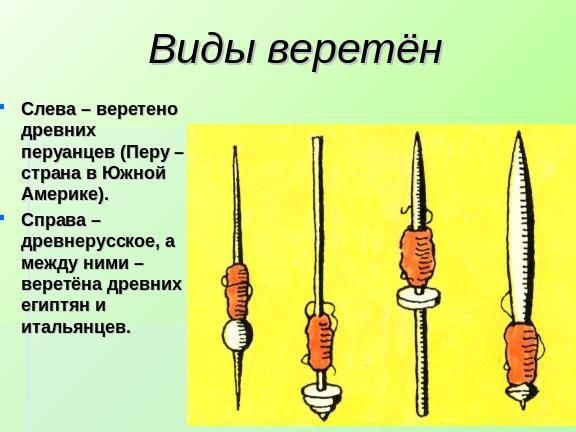

But so that the principle of operation of the self-spinning wheel and the electric spinning wheel is completely clear, I will start with the usual spindle. Hand-made spinning tool in the form of a long, thin rod with pointed tips and a thickening after two-thirds of the length of the entire rod, playing the role of a handwheel.

The spindle, spun by the fingers of the spinner, continues to rotate for a long time due to inertia in the handwheel and twists the strands of wool into a strong thread. The spindle's work consists of two alternating actions; twisting a strand of wool into a thread and winding the thread onto a spindle. In a self-spinning wheel, these actions are witty and simply summarized in one operation.

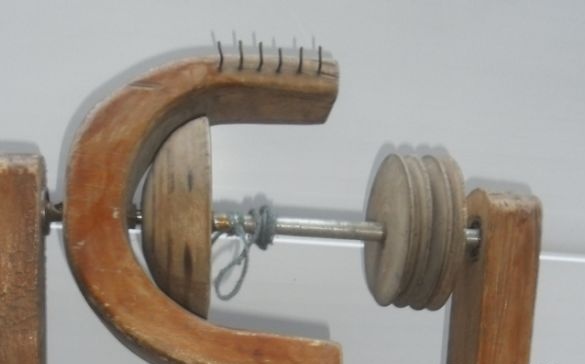

The main unit in the spinning wheel is stag.

Stag beetle is composed of an axis (it plays the role of a spindle), a flyer, a take-up reel and pulleys. The spindle with the flyer rotates from the pulley, the take-up reel is freely mounted on the spindle and rotates from the pulley. The spindle and the coil are rotated by one electric motor, but the coil rotates faster than the flyer. A spindle twists the strands of wool into a thread, a spool through a flyer pulls this thread and wraps itself on itself.

An electric motor uses an electric motor from a household sewing machine with a pedal - a rheostat.

It was problematic to start the spinning wheel at low speeds and made an intermediate shaft with three pulleys, which were machined from wood. Slowed down the spinning wheel. Pulley on a coil with a smaller diameter than on a flyer.

A flyer of three parts: a slice of a plank and on the sides of the lining of plywood 6 mm thick.

The base is a board 30 mm thick, 190 mm wide and 260 mm long. Two wooden racks for a stag and an intermediate shaft are cut into the base. The electric motor was fixed on the same basis with a wire clamp.

The drive from the electric motor using rubber straps.