I have long read or heard somewhere that instead of a heating element for a home-made electric soldering iron with a low voltage (6.3 - 6.9) volts, you can successfully use a cathode heater of a medium power radio tube - 6 P 36 C

or 6 P 45 C.

The coating of the cathode heater electrically isolates its filament from the copper tip of the soldering iron. I decided to try it myself.

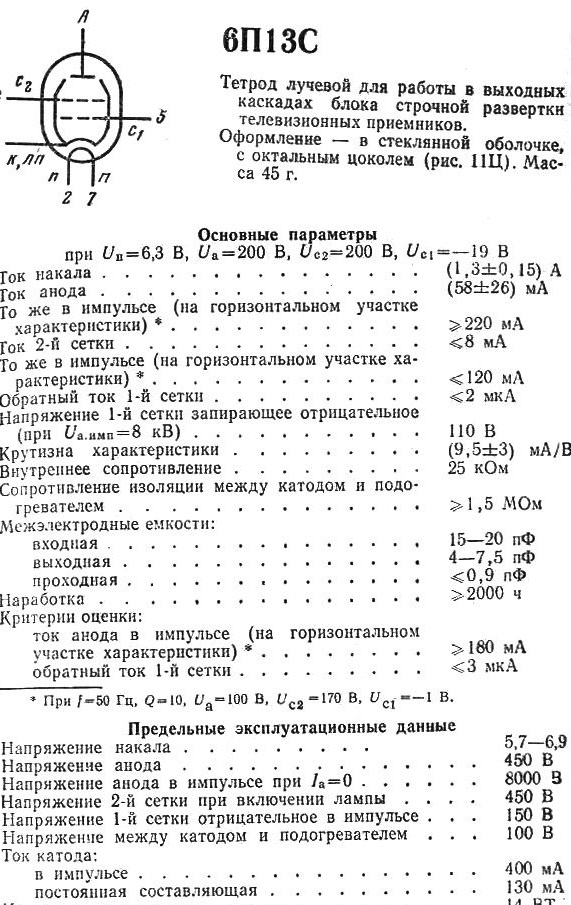

I caught my eye electronic lamp 6 P 13 C.

He put the lamp in a plastic bag so that the fragments of the glass bulb would not fly apart and neatly broke the lamp.

He gently released the heating coil, biting off the lamp legs with pliers.

Copper Rod for Soldering Iron Tip

used from a burned-out 220 volt electric soldering iron.

At the end of the rod, I drilled a channel of such a diameter to the length of the heating element so that there was good thermal contact between the soldering iron tip and the filament.

The ends of the heater are welded to the brass lobe, and those were welded to the legs of the radio tube.

Each end of the power cord is crimped with a brass lobe

and insulated with a porcelain tube from each other and from the body of the soldering iron.

The other end of the power cord is soldered to a DIN-5 plug,

since there is a DIN-5 socket in my power supply unit, an alternating voltage of 6, 5 volts is specially connected to it. The soldering iron tip in the casing is strengthened with an aluminum transition sleeve,

made of 1 mm thick aluminum strip.

Such a homemade electric soldering iron heats up a little longer than a conventional soldering iron

and is determined by the mass of the copper sting and the power of the cathode heater of the applied radio tube.

In my case, it is within 10 watts.

If porcelain insulators are hard to find,

then the connections of the power cord to the cathode heater are wrapped with a thin asbestos thread, which is then impregnated with a home-made heat-resistant thermo-paste.

Thermo - paste is made like this: talc

with silicate glue

mix to the density of sour cream and cover the necessary places.