So the summer comes to an end, it is time to think about how to heat the room in the cold season. After all, this issue will become relevant literally in a month, or even less.

One of the most productive devices in terms of heating can be attributed to a furnace called Buleryan. It is a modified potbelly stove in which firewood (you can use other fuel) burn for a very long time, and the room is heated as efficiently as possible.

The main feature of such a furnace is a convection system. Around the firebox are pipes that quickly warm up when burning fuel. Further, cold air begins to displace warm air from the pipes and as a result, natural circulation occurs. Thanks to this, the room warms up quickly and as efficiently as possible. Such a stove can heat not only one room, but even a small two-story house.

If you go even further, then for such a furnace you can make a water circuit. This will allow heat to be supplied to rooms or other necessary rooms. Also in this case, the system becomes more secure, since the outer part of the furnace does not heat up to high temperatures.

The system has special adjusting mechanisms that allow the furnace to work automatically in two modes. First, the furnace warms up to the required temperature, and then it enters the combustion support mode, while the fuel burns slowly and the furnace only maintains the desired temperature. Such a furnace can burn on one load of fuel for up to 12 hours.

The stove also differs from ordinary bourgeois in that it burns wood gas, that is, solid fuel first turns into a gaseous state, and then burns in a separate chamber. Thanks to this, an efficiency of up to 80% is achieved.

You can clearly see how the oven works, you can see on the video:

Materials and tools for homemade:

- metal pipes with an outer diameter of about 50-60 mm;

- sheet metal (thickness 4-6 mm);

- welding;

- a tool for cutting metal;

- pipe bender;

- tap to remove condensate;

- a piece of pipe with a diameter of 350 mm;

- asbestos cord;

- materials for the manufacture of dampers, legs and other things;

- a standard set of tools.

The manufacturing process of Buleryan:

Step one. Device diagram

Before proceeding with the assembly of the furnace, you need to study and understand the scheme of its operation, since improvisation will not work out too much here. The design is all-metal, around the firebox there are curved pipes for circulation and heating of air. Also important is the arrangement of the furnace, as well as the systems for regulating and controlling combustion.

In order for the stove to work as efficiently as possible, the chimney should be insulated. Mineral wool is suitable for these purposes, its thickness should not be less than 3 mm.

Even in the system there should be a blow through which combustion air will enter the furnace. It is possible to organize an ashpit, but it is not particularly needed, since very little waste is generated during slow burning of waste.

Even to increase the efficiency of the furnace, a double back wall can be made in it.

Step Two We make convector elements

Thanks to the convector, the air quickly warms up. For its manufacture, pipes of about 1.2 m length will be needed, the thickness can be different, the thicker the pipe, the more air per unit of time can warm the furnace. Pipes need to be bent using a pipe bender with a radius of 225 mm. then they are staggered.

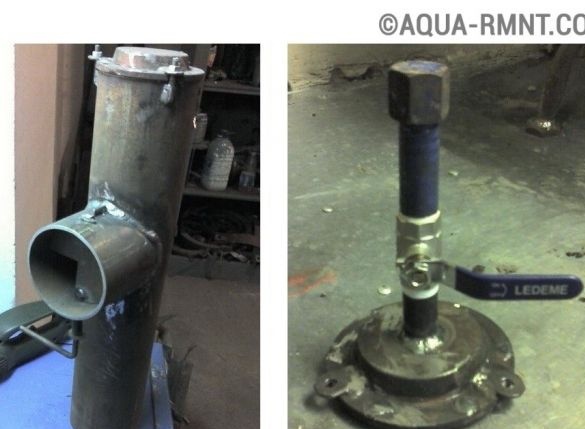

Step Three Device for removing moisture and smoke

Condensation may accumulate in the oven. To remove them, you need to install a special crane. This device has a T-shape, when you open the faucet, smoke rises up, and moisture flows down. Since the draft will deteriorate when the crane is opened, it must be used only for its intended purpose.

Step Four Chimney damper and blower

In order to be able to regulate traction, a special shutter is provided in the system, which is made of a steel plate.

For the blower, you also need to make a damper so that you can control the air supply. In order for the shutters to be rigidly fixed in the required positions, springs are installed on their handles.

Step Five Buleryan's front door

This is the most difficult process of creating a furnace. The front door should be closed as tight as possible, that is, with a minimum clearance. The denser the door closes the stove, the more efficiently Buleryan works.

From a part of a large-diameter pipe, it will be necessary to cut two rings, nor should they enter one another almost tightly. For these purposes, you need to cut two pieces of pipe with a length of 40 mm and a diameter of 350 mm. Next, one segment must be cut and expanded. Well, then the front part of the stove is made, a smaller diameter ring is used here.

The second ring is necessary when mounting the door. Its author welds to a circle of sheet steel.

Next, another ring is welded to the door, in diameter it should be slightly smaller than that which is welded to the front side of the furnace. A gap forms between the two rings, an asbestos cord is laid here, it acts as a sealant. Well, then you can mount the damper.

Step Six Assembly of the frame of the stove

Now you need to return to the bent pipes again. Holes are made in the first two pipes, then tubes are installed in them, they connect convection elements to the furnace. The diameter of the tubes is only 14-15 mm, and their length is in the range of 150 mm. Thanks to these tubes, air will flow into the combustion chamber when the furnace heats up.

Next, the pipes are welded together, thereby forming a frame. You will also need to make a partition, it is made of sheet steel, its thickness should be at least 6 mm, since when the fuel burns in the furnace, a high temperature is formed.

The gaps between the pipes must be closed with sheet metal, it is welded by welding. By welding the back wall, the furnace body will be formed. For the manufacture of metal strips of the desired length and width, first you need to make cardboard templates.

Seventh step. The final stage

It is still important not to miss such a moment as the locking mechanism for the door of the stove, it consists of an eccentric and a hinge, which is located on the wall of the stove. The further the eccentric is twisted, the denser the door is adjacent to the furnace, thereby achieving maximum tightness. To make such a device, you will need to carry out milling and turning operations.

Well, now you just need to weld the hinges and hang the door on the stove. You will also need to make legs for her so that she can stand reliably.

In conclusion, we can say that it is much more difficult to assemble such an oven than an ordinary potbelly stove. However, according to many, the time and money spent here makes sense, since the furnace is convenient, economical and highly efficient.