Many lucky owners of printers have already installed a continuous ink supply system. The advantages of such an improvement in the printer are obvious: you do not need to buy expensive cartridges, you can always see how much ink is left in the tank, with a decrease in ink level it is enough to add the right amount, the price of one printed copy is reduced several times and finally you can make such a system do it yourself. Auto RU homemade also tired of constantly changing cartridges and he decided to make a CISS on his own.

Tools and materials:

-Scissors;

-Duct tape;

- Instant glue;

-Medical gloves;

-Screwdriver;

Syringes

-Cartridge;

-Printer ink;

-Thin transparent tube;

The author purchased the handset in a radio store, paint in a store. Moreover, the paint is needed in jars, if the paint in syringes will need to be poured into a suitable container.

Step 1: cartridge preparation

First, the author washed the detergent tubes and dried them. Then he scored water in the syringe, inserted the needle into the hole in the upper part of the cartridge (under the sticker) and washed each chamber. He carefully removed the top cover of the cartridge. Flushed the inside of the cartridge. All is well dried.

Step 2: reassemble the cartridge

Replaces the sponge. Installs tubes in the hole on the cartridge cover. Each color has its own tube. If necessary, the holes should be expanded, but the tubes should be inserted tightly. Then glue seals the junction. Glue the top cover to the cartridge. Glues are necessary so that the cartridge compartments are also isolated from each other. There should not be a single non-glued area both around the perimeter and between the cartridge compartments.

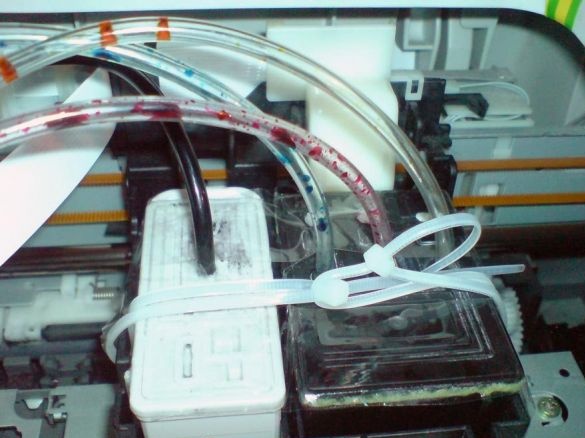

Step 3: Install the CISS on the printer

Opening the printer cover puts the cartridge in its place, the tube leads out. The cartridge is fixed in the carriage with a collar and tape.

Step 4: refill CISS ink

Typically, there are two openings for each color on the cartridge cover. In one, the author inserted a tube, the second should remain open until the end of the refueling. Then the master draws ink into the syringe and slowly fills the cartridge compartment through the tube with ink. It is important not to mix the colors and refill the ink of the color that was originally there in each compartment. By filling the compartment and the tube, the author closed the hole in the tube with chewing gum. Thus fills all the compartments of the cartridge. When filled, seals the remaining holes in the cartridge cover.Each ink bottle lid makes two holes. One in the center of the tube cover. The second author did as follows: he made a hole with a syringe needle on the side of the lid, inserted a needle into the hole, and inserted a piece of foam in the upper part of the needle. The result is an air duct with a filter. By removing the chewing gum from the tubes, it inserts them into the holes in the covers by color. Tubes lowers to the bottom of the tank, but not all the way.

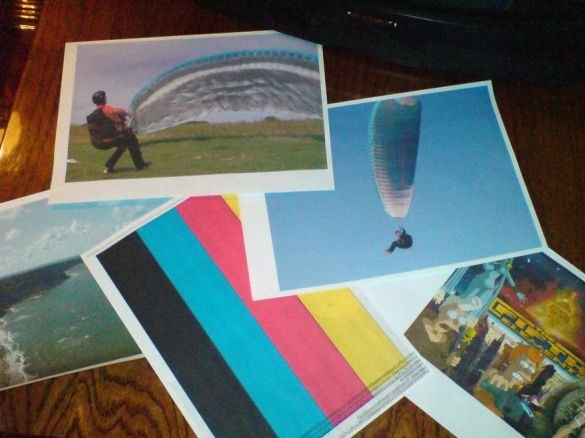

Step 5: Zero and Run Ink

In most printers, the software does not allow reuse of the cartridge. In order that the printer does not "swear" it is necessary to reset the cartridge chip. For his printer, the author downloaded a special utility. Installed it, selected the counter reset function (with the printer turned on) and confirmed the action. Turned the printer off and on again. After the zeroing operation, it is necessary to drive out the ink by turning on the nozzle cleaning mode.

A little from myself.

1. For washing, it is advisable to use not water, but a special washing liquid sold in the same place as the ink for the printer.

2. When installing the cartridge in the carriage, the tubes must be routed correctly. The carriage moves and it is necessary that the tubes do not catch anywhere.

3. It may be necessary to make holes for the tubes in the housing or cover of the printer.

4. It is better not to disassemble the cartridge (as the author mentioned at the end).

5. The utility that the author installed works with old OSs, so I don’t provide a link to it. The network is full of instructions on how to reset your cartridges.

6. This manual is more suitable for printers with 2 cartridges (one black, one color) because for such printers CISS is almost never found on sale. For printers where several color cartridges are better to buy a ready-made CISS (although you can do it).

7. Ink is better to use branded.

8. The ink level in the container should not drop more than half.