Nowadays everyone knows perfectly well, the country is in full swing construction private houses, any choice would be only money. Elite villages are now growing like mushrooms after the rain, houses are being built instantly using the latest technologies and materials, as well as cheap labor of shabashniks from the CIS.

Well, as a simple people, as always, there is no money, so you have to cost yourself, to study all the intricacies of construction directly in the process. It doesn’t always work out qualitatively, but on a budget, with decent money savings)

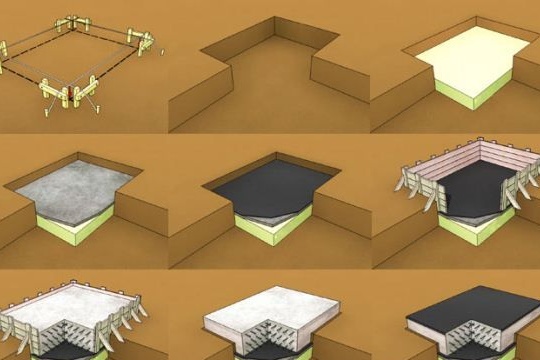

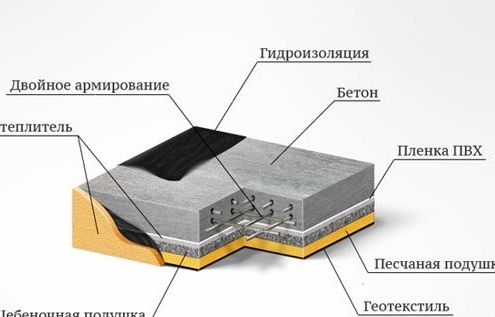

And so, in order to fill in the monolithic foundation, the site is first cleared, then a solid hole is dug, a sand cushion is laid on the bottom and everything is carefully compacted with periodic watering, a layer of gravel of at least 20 cm is laid on top of the sand cushion and it is also compacted. After the measures taken, a plastic film in several layers is laid on top for waterproofing.

Then the fittings are laid, strapping is done, an important point that should not be missed — the distance from the reinforcement to the ground should be at least 2.5-5 cm, that is, the reinforcement must be inside the solution when pouring. Formwork is done and concrete is actually poured, according to the author, and indeed according to the mind, for pouring large areas it is best to order a ready-made mortar and immediately fill the entire area. Take measures with a vibrator, that is, expel excess air so that the solution evenly fills all the voids.

But in order to understand in more detail everything and understand the whole essence of this venture, you should carefully study the photo report made by the author for his followers, as well as look at the list of necessary materials and tools.

Materials

1) sand

2) gravel

3) plastic film

4) concrete

5) board

6) timber

7) fittings

8) knitting wire

9) wedges

Instruments

1) shovel

2) a hammer

3) a hacksaw

4) roulette

5) ax

6) pliers

7) vibrator

8) ramming machine

And so for starters, the author allows us to get acquainted with the drawings and diagrams.

Done.

That's all, I hope you enjoyed it) Thank you for your attention!