In the manufacture of various carpentry, it becomes necessary to set the cutting depth on the machine, setting the saw blade higher or lower. Some machines have a special scale, others set the saw measuring its height with a ruler. Author homemade decided to make a device with which you can quickly and accurately measure the height of the saw blade or set the size of the guide. Basis fixtures is a digital caliper. The author posed and implemented the task of easy mounting and dismounting of the caliper to solve other problems with it.

Tools and materials:

-Digital vernier caliper;

-Neodymium magnet;

-Plywood;

-Fasteners;

-A screwdriver;

-Sandpaper;

Step 1: Design

First, the author of the home-made program in a special program made an altimeter project. You can download the project on this.

Step 2: Cutting Parts

Cut out of plywood, according to the patterns, part of the altimeter.

Step 3: Holes

A printed sheet with a template sticks to the cut parts. Drills and countersinks holes according to the marks of the template.

Step 4: Build

Collects parts by fastening them with screws.

Cleans with sandpaper.

Fastens the magnet.

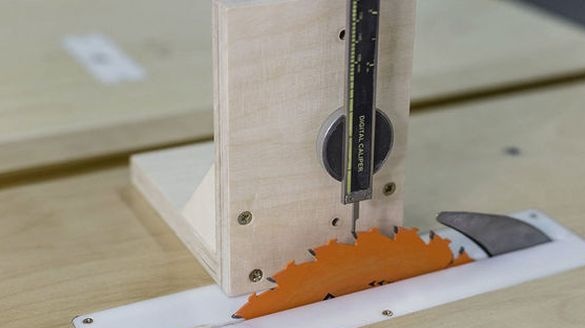

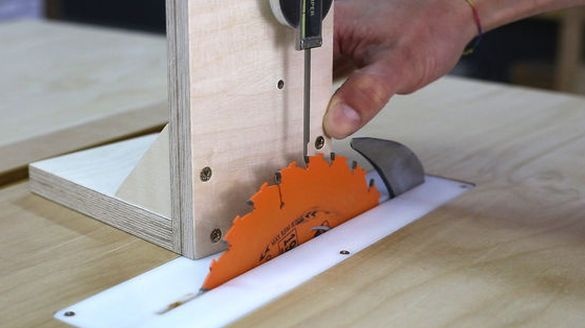

In order to use the altimeter, it is necessary to fix the lower part of the caliper to the magnet.

Then set the altimeter to the surface of the table. Set the caliper depth gauge to the measuring point (e.g. saw blade). Reset the caliper. Now, when you move the measuring point, the caliper display will show how far it has been moved.

A few examples of using an altimeter.

Measuring the height of the blade.

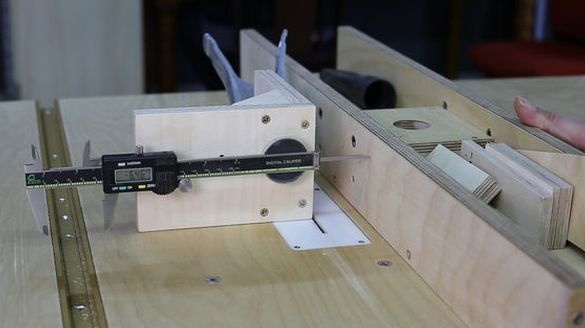

Depth measurement.

Measuring the distance between the cutting disc and the guide.

You can watch the video in more detail.