The sofa is the heart of the house. It serves as an element of interior decoration, helps to relax after a hard day. A sofa is not just an item of furniture. It will certainly become the hallmark of the house and the center of attention of your guests.

In this article you will learn how to make a sofa with your own hands no worse, and perhaps better than those sold in furniture stores. You will see what elements the sofa consists of and what materials are most often used in the process of its manufacture.

Do not forget that home-made furniture saves the lion's share of the family budget. You decide, for example, to make a sofa yourself, its cost will amount to two, or even five times lower than the market!

However, it depends on the materials chosen and the particular construction taken. A folding sofa will cost more, but if this is your first product, opt for the project described in this article - it is perfect for those who set out to learn how to make upholstered furniture.

Make a sofa do it yourself, - and you will be convinced by your own example that there is nothing complicated!

So let's get started.

For work you will need the following materials and tools:

1. Tools:

- jigsaw. If you do not have a jigsaw - it does not matter: use a hacksaw on a tree, especially since it is useful to you in the process of sawing up bars;

- pneumatic furniture stapler. If you intend to make only one product, use a mechanical stapler - it will cost less;

- screwdriver;

- a grinder or planer for grinding sharp corners of the frame;

- staple extractor or sharp screwdriver;

- a sharp knife for cutting foam;

- scissors;

- sewing machine for stitching elements of the upholstery of the sofa;

- roulette.

2. Materials:

- bars with a section of 40-50 mm;

- plywood or any other affordable, durable and possibly lightweight sheet material;

- furniture foam rubber, 50 mm thick. Foam rubber, like many other materials, you can buy in a specialized online store "everything for furniture";

- synthetic winterizer or batting for additional softness of the frame and the product as a whole;

- furniture fabric;

- joiner's glue;

- strong thread for stitching upholstery parts;

- self-tapping screws or furniture screws (when using the latter you will need an electric drill);

- marker or pencil.

Let's get to work.

1. Frame

The basis of our sofa is the frame. It can be of any shape and size, but this article describes the simplest project, which can be made by a person inexperienced in the manufacture of upholstered furniture.

The basis of the frame is made up of wooden bars and slats with a cross section of 40-50 mm or any other size that ensures the strength of the finished product.

Additional rigidity to the frame is given by the sheet materials with which it is sheathed - plywood, OSB, chipboard, fiberboard, etc. Inside the frame is hollow, which makes it relatively light.

IN home The sofa frame is assembled using a screwdriver and self-tapping screws. The holes for the screws can be pre-drilled with a drill, and the screws themselves should be lubricated with carpentry glue when drilling.

Also, glue is often used at the junction of wooden parts before they are joined using self-tapping screws. In this case, they are pressed against each other with clamps for a while.

In addition, when assembling the frame, it is convenient to use all kinds of angular and curved metal fasteners.

The length of our sofa will be 3 meters. It is quite roomy and consists of two equal parts - 1.5 m each. In the photo below you see one of them - the left side of the sofa.

2. Frame and mattress

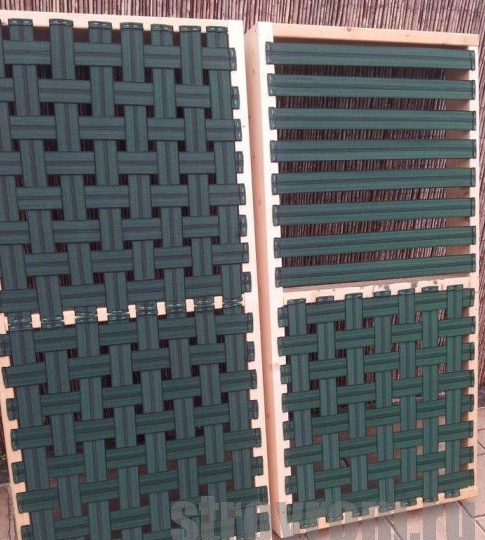

The frame of the future mattress - the base of our sofa - is made of planks. For greater comfort, a binding of furniture belts is arranged.

It is not difficult to make it: first, the belts are fixed horizontally with a stapler, then you must bind and fix the belts perpendicularly - vertically.

The photo shows what we should get in the end. These are the two components of the mattress.

3. Back

In the photo below - the backrest frame of our sofa, sheathed in plywood. Please note that the frame itself is made of wooden blocks, and metal connectors are used to fasten parts.

The back is hollow and light, it is comfortable to work with. The form in this case is as simple as possible - rectangular in profile. Without much effort, you can make it sloping, increasing the width at the base and reducing the width of the frame at the top.

4. Lateral parts

By analogy with the back, we also manufacture the side parts of the frame. It should be noted that the protruding bars that are visible in the photo in the future will serve us as the basis for foam rubber. But more on that later.

5. Pasting with foam mats

After assembling the frame, proceed to mount the foam.

Pieces of foam rubber of the required size and shape are pasted over the top and front of the back, as well as the inner surfaces of the side elements. We put foam on the mattress over the binding.

The glue can be applied with a wide brush or used in the form of an aerosol. Immediately after applying a layer of glue, we press the foam to the surface and leave it for a while (usually no more than half an hour) until it sets.

6. Sintepon (batting)

In order to hide irregularities, smooth out sharp transitions and add volume, back, sides and, if desired, the mattress is wrapped with sintepon or batting.

Before proceeding to this stage, it is necessary to grind all the sharp corners of the frame so that the upholstery does not rub and lasts as long as possible. This operation is carried out using a grinder, plane or just large sandpaper.

7. Fabric upholstery.

Cases are usually sewn on finished patterns and patterns. If there are none, you can make them yourself by applying and trying on fabric to each of the elements of the sofa, whether it is a back or a pillow. Some of them can be sewn with zippers for easy cleaning and washing.

Covers can be cut strictly in shape or seized and grabbed with a stapler in those places where the design allows.

In extreme cases, sewing covers can be entrusted to specialists from the studio. Their design is very simple and inexpensive.

8. Sofa assembly

The final assembly of the sofa is carried out as all its elements are covered.

Such a sofa can be done in 2-3 days of hard work, without special skills. Its design is simple and relatively inexpensive.

Be sure that you will be able to surprise your family and will have something to brag to your guests!