This article will discuss the manufacture of do it yourself rocking chairs. Author homemade honestly admits that he spied the design of the chair by famous designers of furniture . Since buying such a chair is quite expensive, he decided to try to make it with his own hands.

Tools and materials:

- Fittings 20 mm;

-The cloth;

-Dye for fabric;

-Paint for metal;

-Varnish;

-Welding machine;

- Angle grinder;

-Sewing machine;

Step 1: Design and procurement of material

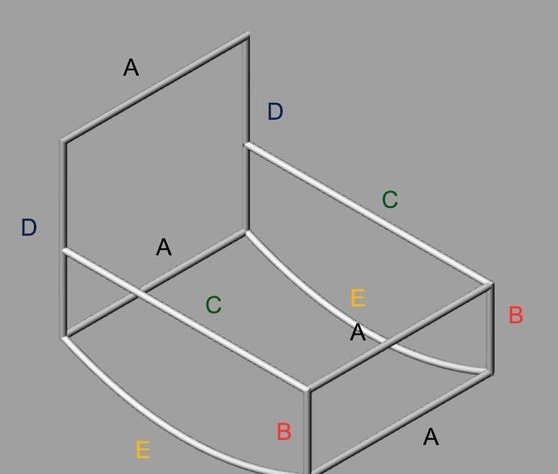

First, the author developed the project in a special 3D program. Then he acquired fittings in the following size: A: 4 x 650 mm, B: 2 x 268 mm, C: 2 x 867 mm, D: 2 x 600 mm, E: 2 x 896 mm.

Step 2: Rebar End Processing

So that the reinforcement fits snugly to each other, the author decided to work on its edges. According to the drawing, the rods A processed from both ends, the rods B and C from one. Rods D and E do not need to be processed.

Step 3: Welding

Welds the frame of the chair.

Bends the E-armature. Since the author does not have special equipment, the author inserted reinforcement between two trees and bending it, he achieved the correct uniform shape on both runners.

Welds it to the frame.

Step 4: Strength Test

After welding, the author decided to check the rocking chair for strength. Made a suitable fabric temporary seat. Since the chair passed the test, the author proceeded to the next step.

Step 5: Cleaning the seams and coloring the chair

A sander processes seams, removes burrs and sharp edges.

Using soapy water, removes oil stains from the surface. Dries the chair. Do not forget about personal protective equipment primer and paint the rocking chair. And the primer and paint are applied in two layers with a small exposure. Drying time of soil and paint for 24 hours. After drying, the paint is applied.

Step 6: Making the Seat

For the seat, the author acquired a piece of cotton 1200 mm to 1300 mm white. He painted it with a special paint in a washing machine.

Then the fabric was folded in half and sewn on a sewing machine. The result was a piece of 1200 mm by 600 mm.

The next step was fabric sewn onto the frame of the chair.

Rocking chair is ready.

Since the author is the first rocking chair, he is pleased with his work, but he still has a few remarks: the skids must be made less curved, powder coated with the surface, and use a pipe instead of reinforcement.