Nowadays, a cutting board has long ceased to be a simple tool. Today it is a full-fledged element of decor in the kitchen and should correspond to its rank.

Both amateur and professional kitchens use cutting boards of two types: from wood and from different types of plastic. At first glance, a plastic board may seem much more practical than a wooden one, because it is easy to clean and has a long life.

However, the first impression is misleading. A real cook, who is also in love with his profession, will certainly choose a wooden board and take care of it carefully. What happens from this?

The fact is that any board is created, first of all, for cutting products and "works" together with a knife. A good knife is the honor and dignity of a cook and it costs a lot of money as usual. On a plastic board, the knives quickly blunt and require constant eyeliner and sharpening. But for the knife to serve as long as possible, subjecting it to frequent sharpening is not worth it.

In such a situation, a wooden board saves, which carefully takes care of the cutting blade and prevents it from becoming dull too quickly. When using such an eyeliner board, the knife is quite enough.

To be sure of the quality of the products, we decided to make a cutting board do it yourself.

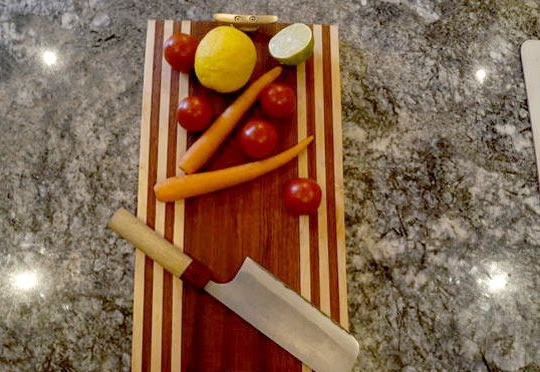

The board is more decorative - the more wood species is used in its manufacture. Thus, the wood alternates, creating a multi-colored pattern of natural textures and shades, and we get a unique product, a copy of which does not exist in the world.

For such a serious attribute as a kitchen cutting board and wood species, you need to choose the appropriate - "serious": oak, maple, beech, white acacia, walnut and others in this spirit.

In addition to the fact that wood must have the necessary strength and durability during operation, it must also create a rich color gamut. This effect is achieved by using light and dark wood species, as well as reddish, reddish, and even purple wood in the manufacturing process of one product.

If you, like us, have managed to get at least a couple of boards that vary in color, you can get to work and try to make a chopping board for your own kitchen.

So for work we will need:

1. Materials:

- boards;

- carpentry glue (the author applied Titebond® III Ultimate Wood Glue).

2. Tools:

- Sander;

- clamps;

- a circular saw;

- Thicknesser (jointer);

- a brush.

Step 1: preparing the material

Pick up boards without knots and tar pockets, thoroughly dried. They should be approximately the same thickness and match the planned thickness of the finished product.

Dissolve the boards on slats of arbitrary width (from 5 to 30 mm.), Using a circular saw. The cut should be accurate enough, otherwise when bonding parts between them, gaps will form, which in our case is unacceptable.

Compose the pattern from the rails, laying them out in different sequences and alternating dark woods with light and bright ones.

Saw the prepared rails into elements of the desired length and carefully grind the joints. You can do this by resorting to a grinder, but we would advise you to grind it manually so as not to remove the excess, thus provoking gaps during further gluing.

Step 2: gluing elements

To glue the battens, use wood glue and a brush. Thoroughly flush the joints and connect the rails in the order you choose. Clamp the board with clamps in three places, and place a load on top of a sheet of plywood or similar material so that the product does not bend.

Leave the workpiece to dry for 24 hours and continue to the next step.

Step 3: forming a board

All elements are reliably interconnected and you can begin to form the finished product.

To do this, the surface of the workpiece must be processed with a surface gage or jointer.

The edges are usually cut with a miter saw, but if this is not possible, mark and cut off the excess with the usual hand saw in a tree.

Step 4: Finishing

Sand the surface of the cutting board with a grinder or manually. In any case, follow the golden rule, and first use coarse-grained sandpaper and only then fine-grained to give the surface the necessary smoothness.

In the same way, carefully grind the end parts.

Start surface treatment with oil. Use linseed oil for these purposes, since this option is the safest of a number of similar ones. Apply it evenly with a brush, allow to soak and repeat the procedure. Leave for a day in a warm, ventilated area so that both planes remain open for drying.

Flaxseed oil will give the board a noble matte shine and partially protect it from getting wet during cooking and washing.

Kitchen cutting board ready and it, unlike plastic, will require care from you.

First, sand the board from time to time with fine emery paper, removing bumps.

Secondly, after each grinding, re-treat it with linseed oil.

Thirdly, never leave the board dirty for a long time, and also make sure that nothing prevents it from drying after the next wash.

Finally, do not use the same cutting board to process meat, fish and all other products.

If you plan to use the board as a tray, screw the decorative handles around the edges. We did just that.