LEDs, due to their qualities, have firmly entered our everyday life. They are a semiconductor diode which emits light when a voltage is applied.

LEDs have undeniable advantages over conventional light devices, fluorescent lamps, incandescent lamps and discharge lamps. These devices are small in size, they do not have filaments, harmful substances, fragile glass bulbs. Electricity consumption is many times less compared to conventional light sources, and the service life is much longer.

For homemade based on LEDs, there are many solutions in the direction of manufacturing a variety of lighting devices. If you create lighting do it yourself in home conditions then you can apply different junk materials. Therefore, you can do something original with your own hands and save on the purchase of lighting products at retail outlets.

In my article I will tell you how to make an LED lamp from an aerosol can and a faulty energy-saving lamp in half an hour.

The process of making homemade products can be seen in the video:

The list of tools and materials

- aerosol spray can then deodorant;

-screwdriver;

-knife or scissors;

soldering iron;

-tester;

-electronic ballast from an energy-saving lamp or a ready-made driver for 0.3A current;

White LED 1W-15pcs;

pulse diodes FR207-4pcs;

thermal paste;

connecting wires.

Step one. Disassembly of the lamp.

We disassemble the energy-saving components. Disconnect the filament of the glass bulb from the board. Then, if the electronic ballast board is operational, you can wind the secondary winding onto the inductor and power the LEDs through the diode bridge. I will not dwell on this in detail as the alteration of the electronic board has already been described in the previous article Alteration of the driver from the lamps. It is also possible in this homemade product to use a ready-made driver for LEDs with an output current of 0.3A, and the voltage depends on the number of LEDs used in the lamp.

Step Two Making the body of the LED lamp.

LEDs emit heat during operation, so they must be installed on a heat sink. The efficiency of the radiator depends on the thermal conductivity of the metal, its area and shape.In this case, I used an aluminum can of deodorant as its diameter approached the base of the fluorescent lamp and the wall thickness surface area was consistent with the task. First, make sure there is no liquid or residual pressure in the cylinder. Next, we cut off the upper part of the spray can with scissors, and try on the base, and make holes for fixing with screws.

With a knife, we make rectangular cutouts for the passage of cooling air into the cylinder. Then we glue the LEDs on the thermally conductive glue, their location depends on your imagination, subject to uniform distribution. We solder the connecting wires to the LEDs in a serial circuit and connect to the converted board or driver observing the polarity.

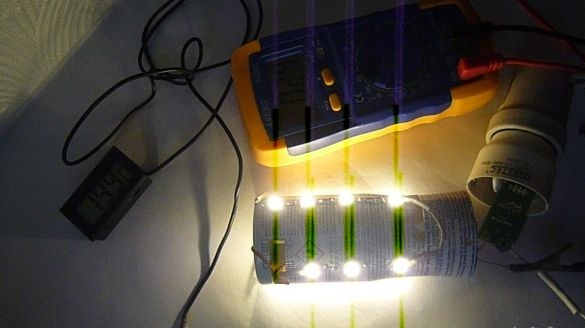

We turn on the lamp in the network and measure the current consumption of the LEDs - it should be no more than the nominal current of 0.3A.

Step Three Checking the LED lamp.

To check the heat transfer of the radiator, I glued the sensor of the electronic thermometer to the lamp housing. The temperature was 45 degrees, which is a good result. It must be remembered that the maximum temperature of the LED housing must not exceed 60 degrees, otherwise it will fail.

And another option with cans - from a can or beer can, you can make a lampshade to the LED lamp by cutting decorative holes.

Example in the photo. Lampshade from a can.

This under the tree can be used as a night lamp and decorative decoration of the interior. It all depends on your imagination and desire to think creatively.

The creation of the LED lamp did not entail significant financial investments. The cost of the driver is 70 rubles (for alteration of the electronic ballast from the energy saving, it’s free at all), 1W-15x3 LEDs = 45 rubles (I bought the LEDs and the driver on Aliexpress). The time for manufacturing the LED lamp was half an hour.

Used aerosol cans and cans received a second life in an unusual perspective.