In the production of welding, it is not always convenient to use the usual standard holder. Small welded parts, it is not convenient to hook the holder, etc. The author found a way to get out of the situation and made a magnetic holder.

Tools and materials:

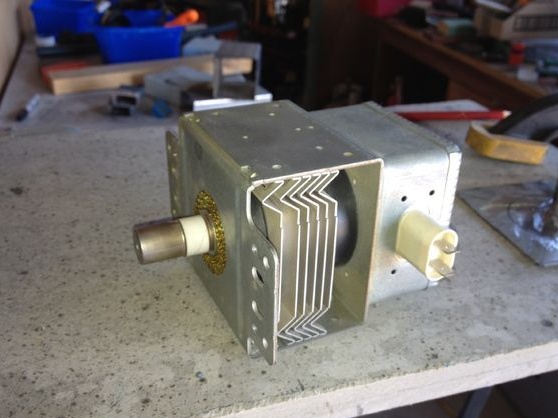

-Magnetron from the microwave;

-A metal sheet;

-Fittings;

-Welding machine;

-USHM;

Step One: Magnetron

Dismantles the magnetron and extracts two magnets.

Step Two: Holder Base

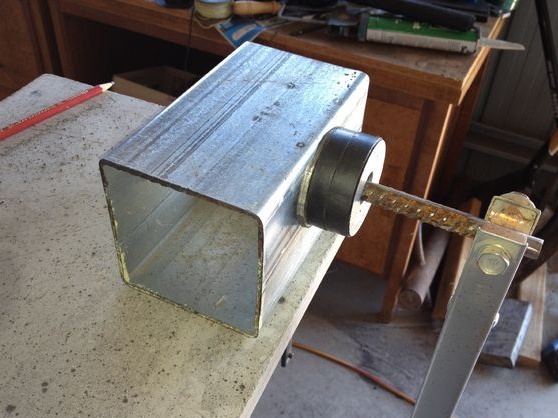

From 3 mm of metal cuts a square of 100 * 100 mm. In the center welds a piece of reinforcement.

He puts a magnet on the armature. Traces its contour, on a metal square. Trims metal to marking.

It cleans the reinforcement and the metal plate welded to it. Installs magnets.

Now you can install the magnetic holder on the surface to be welded, attach a standard holder to it and start welding work.

When using such a holder, one should not forget that when heated, magnets tend to demagnetize.