The laboratory PS-1502DD laboratory power supply with the main advantages of China is cheap and provides voltage, a good case and very accurate digital voltmeter and ammeter. I use from charging batteries to checking and setting up electronics.

Of course, this device has drawbacks, and they are described in some detail at various thematic forums.

Among them, the current cut-off does not always work correctly, with some combinations of events it does not protect the power supply. Also, the lack of a smooth current limitation, which is not at all convenient when charging batteries.

To charge the batteries, we had to consistently turn on the ballast resistance and measure ourselves with incorrect voltmeter readings.

After operation, it is protected by current, when charging the battery, it is necessary to turn off the power to the device and disconnect the battery from the power supply, which is very inconvenient in operation.

Lack of reverse polarity protection.

Strong heating of the power transistor, which operates in linear mode and is installed on the steel part of the case, because of this the transistor overheats.

The moodiness of the circuit during repair in cases of its repair.

After the purchase, the unit for improving reliability was finalized:

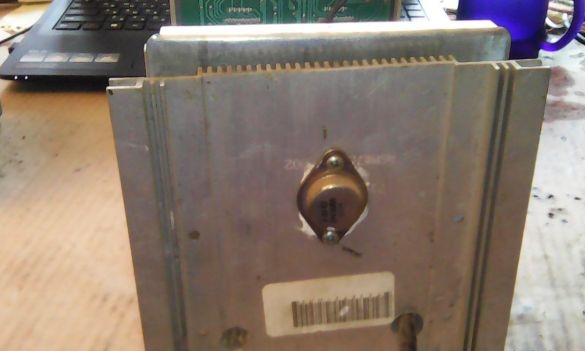

An aluminum radiator is installed on a power transistor with a large area.

Prior to this, the transistor stood on the rear steel wall of the housing.

A powerful diode is installed parallel to the voltage output terminals in reverse polarity, to protect the power supply in case of connecting the battery in reverse polarity.

A fuse is installed in the low voltage circuit.

The control scheme remains unchanged.

Modernized in this way, he worked for several years, which is undoubtedly longer than working without refinement.

In the end, he stopped working, was set aside in the far corner and stood there for about a year.

Repair, knowing the capriciousness of circuitry mood was not, it is a pity to throw out.

I didn’t want to restore the original very capricious scheme, I also did not want to finalize according to the methods found on the network because of the very large amount of work.

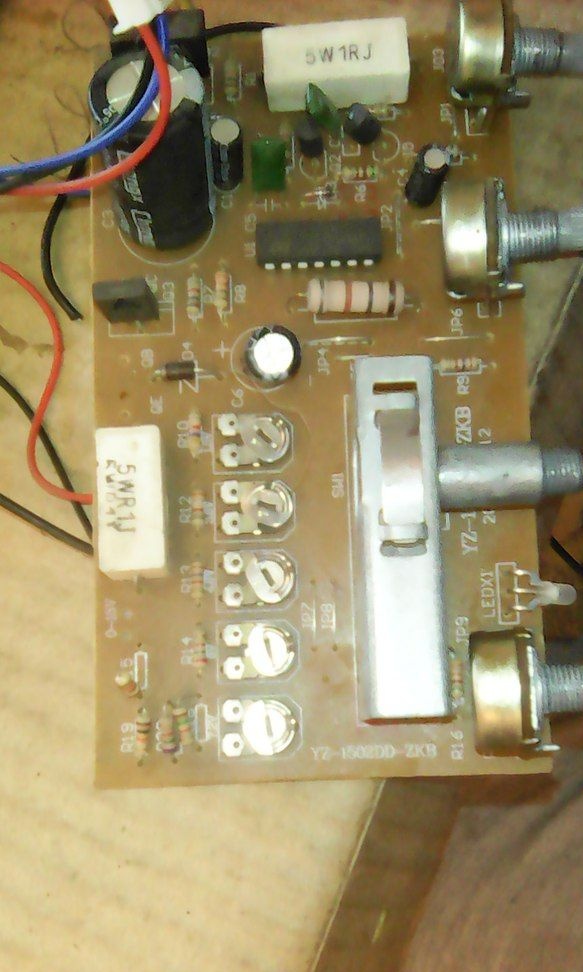

For the sake of interest, along with other details, an impulse stabilizer was ordered from China completely assembled in the form of a finished board, called ""

And very attractive parameters: input voltage up to 35 V, current up to 5 A, smooth adjustment of current and voltage.Very compact dimensions and the main feature does not need a large radiator.

After conducting tests and confirming the declared parameters, it was decided to install it in the power supply, instead of the original circuit, improving reliability and convenience due to the pulsed mode of operation and the presence of smooth current control.

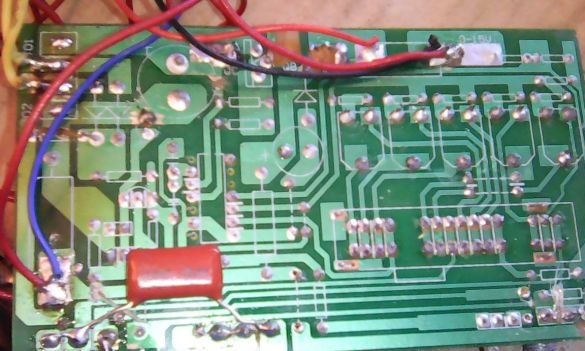

The power supply is disassembled and cleaned. Unnecessary details are ruthlessly removed, including a power transistor with a radiator.

Printed tracks from variable resistors are cut. And wires are soldered to them.

From the stabilizer board, the variable adjusting resistors are removed using extension wires to the wires going to the variable resistors of the power supply.

A rectified voltage is applied to the input, the output is connected to the output terminals through a standard ammeter, and a regular voltmeter is connected to the terminals.

A fuse and a diode connected in reverse polarity protecting against reverse polarity are left in the circuit.

The digital voltmeter and ammeter are very reliable and very accurate. They remained unchanged. They are powered by a separate winding on the transformer and work completely independently, which is very convenient.

Performance has improved significantly!

The maximum voltage has increased from 15 to 30 V. This now allows you to charge a battery with a voltage significantly greater than 12 V. For example, batteries from a hand tool.

Previously, the maximum current was 2 A and at the same time the unit was very hot.

Now, at a current of 3 A, all parts are slightly warm at a current of 4 A, the inductor starts to heat up, and at high voltage, the power transformer.

Based on this, it was decided to operate for a long time at a current of not more than 3 A and for a short time not more than 4 A.

Alteration costs 141 rubles, not including consumables and 3 hours of time.