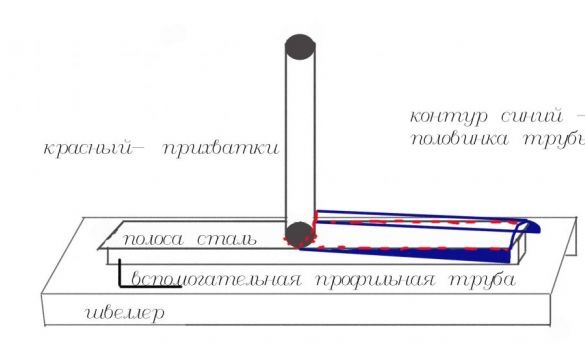

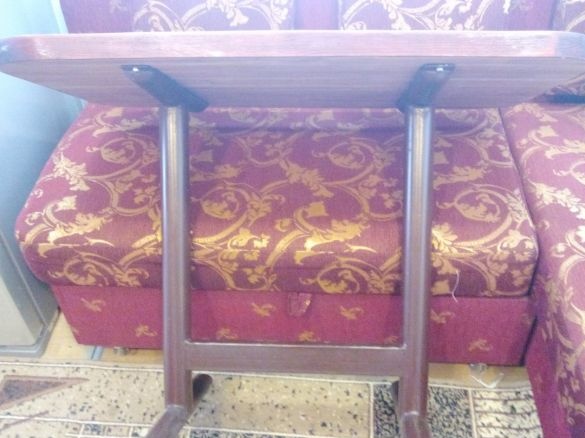

The kitchen often uses corner sofas. A table for such a four-legged corner is very uncomfortable. I suggest using a table frame made of a pipe with a diameter of 59 mm using a welding machine, angle grinder. Production requires the skills of a welder and a lot of free time, the weight of the structure is high.

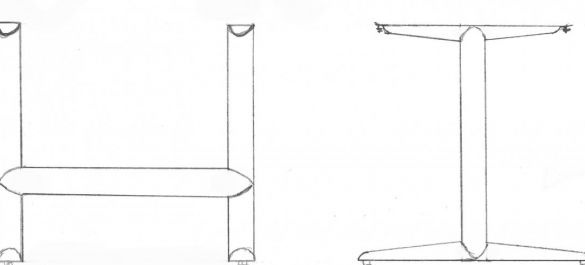

A lightweight look is obtained due to the legs made of conical pipes. The figure is the trick.