Now the market has a huge selection of LED flashlights: from the cheapest to the most expensive professional. One of the problems of inexpensive flashlights is their weak body, which, when dropped, cracks, shatters into pieces. Several of these lights, accumulated at home, led me to the idea of creating a shockproof housing. And the main idea was given to me by my children, who brought another broken toy - a machine with a broken case, a crushed circuit board, torn wires, but with whole big rubber wheels. They became the main part of my future homemade.

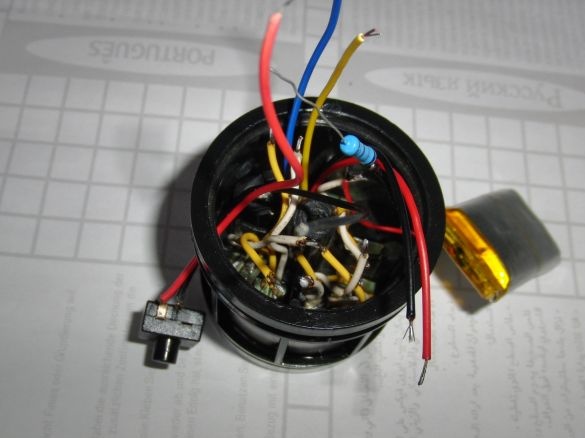

The missing parts were found quickly: LEDs from the flashlight, latch button, washer for the back cover, charger connector, recorder battery, wires, 10 ohm resistor.The assembly was not difficult. We solder the wires to all the LEDs, then glue them from the inside into the holes of the rim. In the disk itself, we drill two holes for outputting wires to the button and the battery.

I turned on the flashlight and battery button inside the tire. The button was glued exactly above the connector located between the LEDs to make it easy to find. The connection scheme is the simplest, and the student will figure it out, but I had to tinker with the "tire fitting" a bit, but it worked out. A washer of the right size fell under my arm, with which I covered the entire bundle of wires.

Homemade is ready! Children now have a new luminous toy, and I have a spare flashlight, which is not afraid of falling.