Offered electronic BP, for powering a 6-volt (4 finger-type batteries) radio from a single battery with a voltage of 1.5 volts.

The proposed power supply unit (PSU) of the radio receiver is made on the basis of a low-voltage voltage converter 1.5 ... 6.0 volts and is designed to power low-power household devices (in particular, a radio receiver) from one finger batteryvoltage of 1.5 volts.

The inverter has good output with a minimum of input elements.

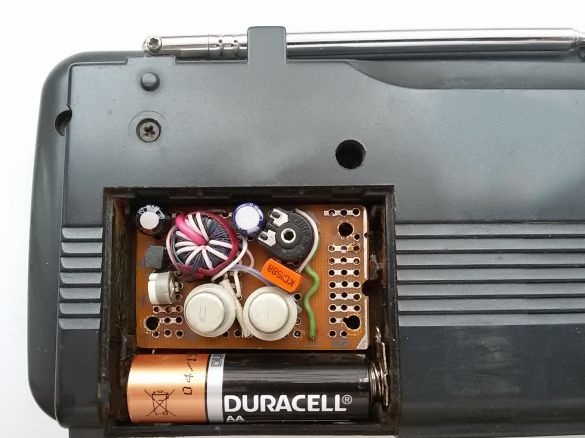

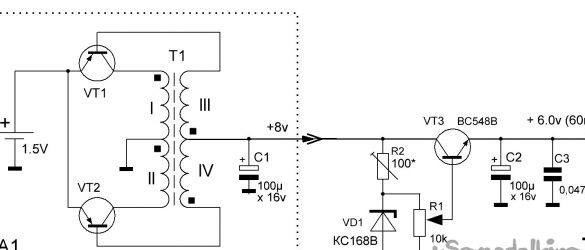

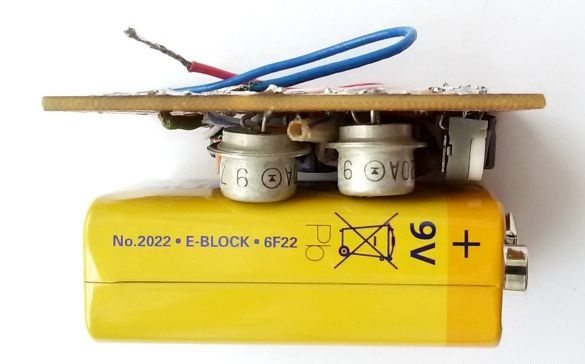

Photo 2 The appearance of the power cassette of the radio before finalization.The transistors VT1 and VT2 assembled a push-pull high-frequency pulse generator (block A1) based on the circuit of A. Chaplygin, “Radio 11.2001, p. 42”. The positive feedback current flows through the secondary windings of the transformer T1 and the load connected between the + 6V circuit and the common wire. The pulse generator is followed by stabilization, adjustment and filtering nodes of the output voltage.

Instead of the RF voltage rectifier, the base-emitter transitions of the transistors of the generator itself are used, which eliminates the rectifier unit of the device.

The magnitude of the base current is proportional to the magnitude of the current in the load, which makes the converter very economical.

Due to the proportional current control of transistors, the losses on their switching are reduced and the efficiency of the converter is increased to 80%.

When the load is reduced to zero, the oscillation of the generator stalls, which can automatically solve the problem of power management.

The current from the battery, in the absence of load, is practically not consumed. The converter will turn on itself when it is required to supply something from it and turn off when the load is disconnected.

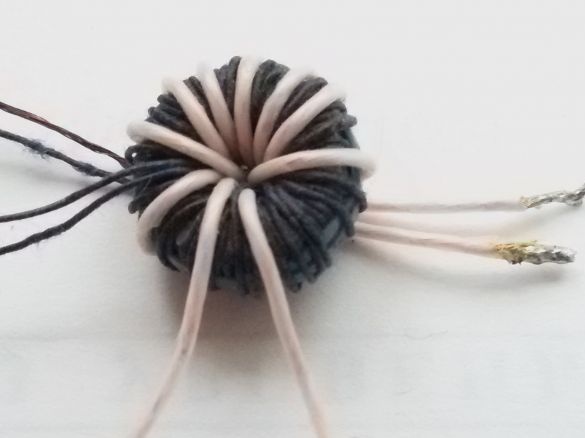

The magnetic circuit of the transformer T1 of the pulse generator is a K10x5x2 ring made of 2000NM ferrite (Photo 5). You can take the ring from the old motherboard.

Step 1. Prepare a ferrite ring before winding the transformer.In order to prevent the winding wire from damaging its insulation, blunt the sharp edges of the ring with a fine-grained sandpaper or file.

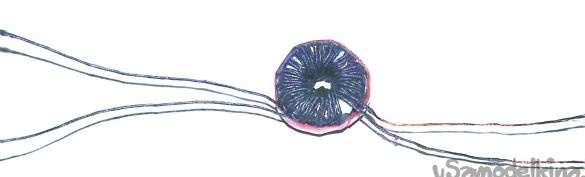

Step 2 Wind the insulating gasket onto the ring to prevent damage to the insulation of the wire (Photo 6). To do this, you can use tracing paper, lavsan or fluoroplastic tape.

Photo 6 Insulation rings

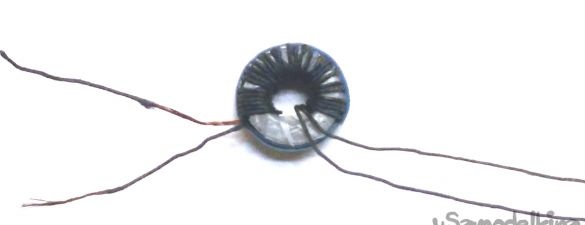

Step 3 Winding transformer windings: primary windings (I and II) - 2 x 4 turns, secondary windings (III and IV) - 2 x 25 turns of insulated PEV, PETV grades, diameter 0.15-0.30 mm. You can also use PELSHO, MGTF grades wire (Photo 7.9) or another insulated wire. This will lead to the formation of a second layer of the winding, but will ensure reliable operation of the voltage converter.

Each pair of windings is wound with a double-folded wire (Photo 7).

Photo 7 Windingtransformer

First, the secondary windings lll and lV (2 x 25 turns) are wound - (Photo 8).

Photo 8 Type of secondary windingstransformer III and IV

Then, also in two wires, the primary windings l and ll are wound (2 x 4 turns).

As a result, each of the double windings will have 4 wires - two on each side of the winding (Photo 9).

Photo 9 Viewtransformer after winding

When winding all the coils, one direction of the winding must be strictly observed and the beginning and end of the windings marked. If these conditions are not met, the generator will not start.

The beginning of each winding is marked on the diagram with a dot at the output. In order to avoid confusion, we can take for the beginning of all the windings of the wire extending from below, and for the end of all windings - conclusions from the top.

Step 4 We solder the wire of the end of the winding (III) and the wire of the beginning of the winding (IV). It turns out the secondary coil of the transformer T1 with a central output. We do the same with the windings l and ll of the primary coil.

For operation in low power converters, as in our case, transistors BC548V, A562, KT208, KT209, KT501, MP20, MP21 are suitable.

Transistors should be selected based on the permissible values of the base current of the transistor (it must exceed the load current) and the reverse emitter-base voltage (it must exceed the output voltage of the converter).

We assemble the converter according to the scheme, on a universal mounting plate (Photo 10). The input, output and common bus of the converter are brought out by a flexible multicore wire.

Photo 10 Converter 1.5 - 6.0 volts.

Photo 11 Converter (side view)

The converter board and AA battery (1.5V) are installed in the battery compartment of the radio.

Photo 12 Placement of the converter with a battery in the receiver

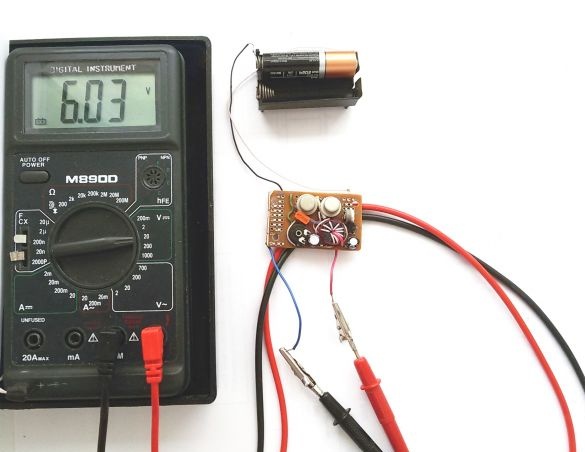

We check the correctness of the assembly of the converter, connect the battery and check with the device the presence and magnitude of the voltage at the generator output (+ 8V) and (+ 6V) at the BP converter.

Photo 13 Converter test

If generation does not occur and there is no voltage at the generator output, check that all coils are connected correctly and swap the ends of one of the T1 transformer coils.

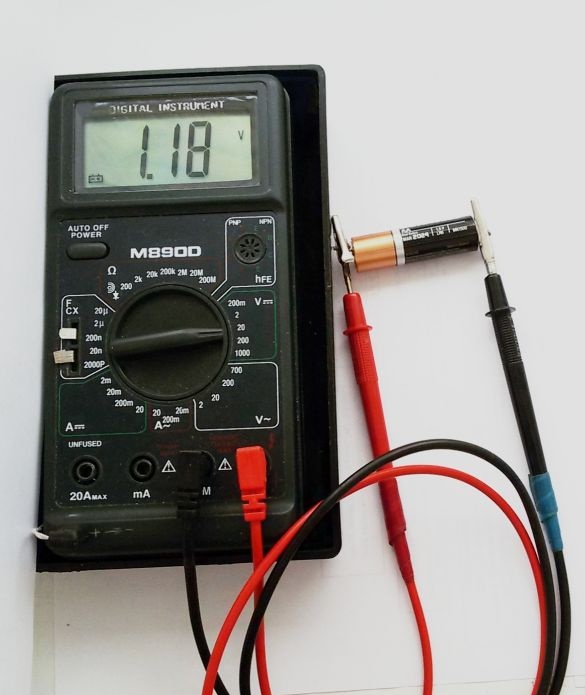

The converter is capable of working even with a decrease in the input voltage of the battery to 1.0 - 1.2 volts.

Photo 14 Battery used during testing.