And so let's take a closer look at what the author needed and how he performed the construction work.

Materials

- block 200x400x200

- Red brick

- refractory brick

- board

- timber

- thermometer

- door hinges

- metal pipe

- stove door

- nails

- hacksaw

- hammer

- Master OK

- shovel

- level

- screwdriver

- roulette

- mallet

And so, for starters, you should understand a little what cold smoking is and how it differs from the hot smoking method.

From time immemorial, people have been giving meat and fish products to fire and smoke, this is necessary so that the product is stored for a long time. In the process of cold smoking, meat or fish are dehydrated and dried under the influence of smoke with a temperature of 18-25 degrees. Yes, the temperature according to the author should be just that.

With cold smoking, you need quite a lot of time from one day to a week, but then what result.

You can smoke in this way a variety of products such as meat, lard, fish, chicken, cheese, or some other kind of exotic there. Cold smoked products are then stored for a long time and do not deteriorate, subject to storage conditions and temperature conditions. To begin construction of the smokehouse, the author first decided on the place and cleared it, made a markup. Then he proceeded to laying the foundation of the smokehouse from blocks 200x400x4200, as you can see in the photo the author did not prepare the foundation, but still it should be shallow. Laying starts from the corner, observing the tie between the blocks, uses the level.

Then the author proceeded to the manufacture of a smoke chamber directly, made the foundation of the structure out of timber.

Then the author proceeded to the manufacture of a smoke chamber directly, made the foundation of the structure out of timber.

Next, the master grabs the wall with a board.

Next, the master grabs the wall with a board.

Then the author installs the resulting camera on the base of the smokehouse.

Then the author installs the resulting camera on the base of the smokehouse.

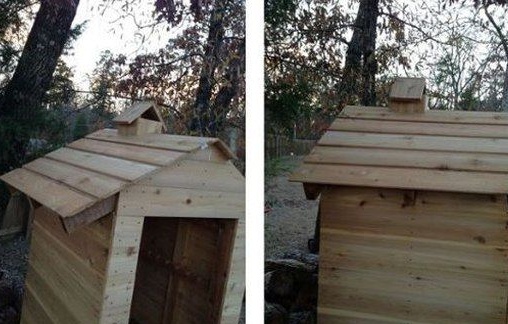

After the creation of the roof truss system begins, here the author made a rather long lap, it will serve as a shelter for a small supply of firewood for the smokehouse, as well as protection from atmospheric precipitation.

After the creation of the roof truss system begins, here the author made a rather long lap, it will serve as a shelter for a small supply of firewood for the smokehouse, as well as protection from atmospheric precipitation.

And sheathes the roof with a board, but for the durability of the building it is better to use iron, laying it on top of the board and securing it with self-tapping screws. Also on the roof there is an outlet, it serves to exit the excess smoke.

And sheathes the roof with a board, but for the durability of the building it is better to use iron, laying it on top of the board and securing it with self-tapping screws. Also on the roof there is an outlet, it serves to exit the excess smoke.

As soon as the work with the smoking chamber is completed, the author proceeds to the laying of the furnace, for a start he pours a shallow foundation and begins the laying.

As soon as the work with the smoking chamber is completed, the author proceeds to the laying of the furnace, for a start he pours a shallow foundation and begins the laying.

The inner part is laid out of refractory bricks, and the top is covered with red ceramic. Then, a door is installed in the resulting furnace.

The inner part is laid out of refractory bricks, and the top is covered with red ceramic. Then, a door is installed in the resulting furnace.

That's actually all I wanted to talk about in this article, the author advises building such smokehouses in my area and smoking my products. There is also video material on the proper smoking and preparation of products

That's actually all I wanted to talk about in this article, the author advises building such smokehouses in my area and smoking my products. There is also video material on the proper smoking and preparation of products