Those people who often do carpentry for themselves or on order, just need to have a stationary circular saw in their carpentry workshop. Working on a stationary machine is very convenient and, again, the back position is straight, which is important for prolonged and monotonous work.

Today in the shops there is a large selection of machine tools and tools, but a couple cannot afford a simple joiner and have to get out of the situation using natural ingenuity. For example, the master made a stationary saw from a hand-held circular saw, how did he do it? We look further.

Materials

1. hand saw

2. plywood 11 mm

3. bolts m-8 with a furniture hat

4. wood screws

5. circuit breaker

6. wire

7. beam 40x40

8. furniture rails

Instruments

1. jigsaw

2. hand saw

3. drill

4. screwdriver

5. hammer

6. screwdriver

7. pliers

8. ruler

The process of creating a stationary circular saw.

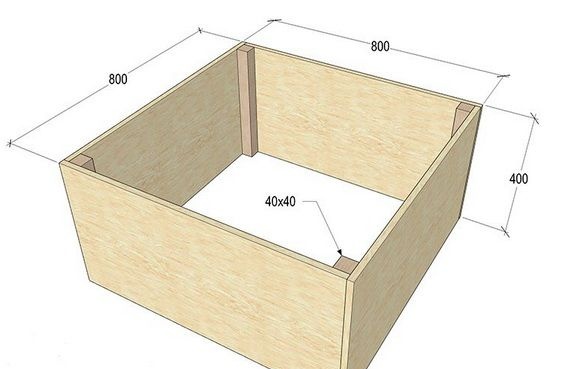

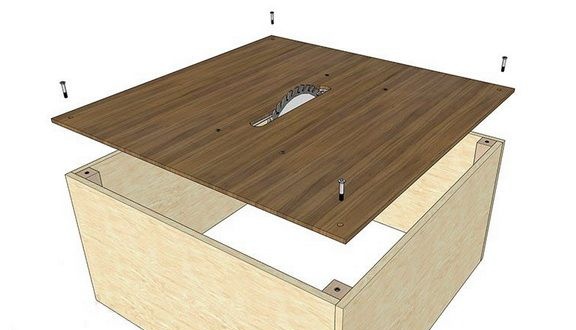

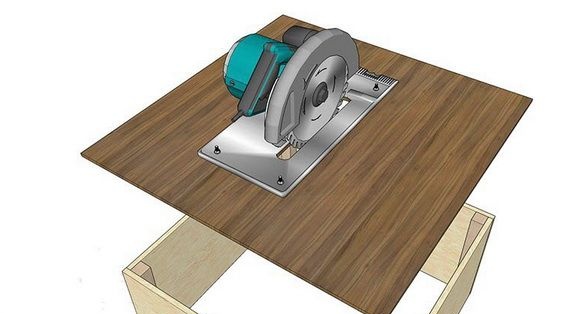

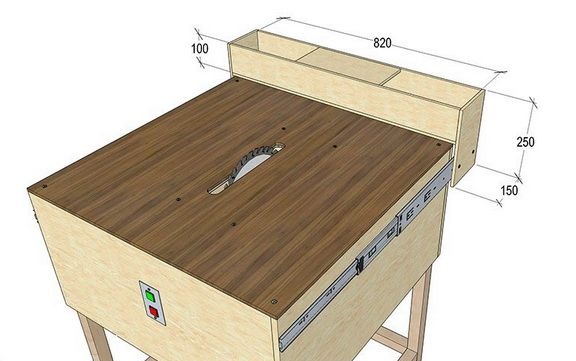

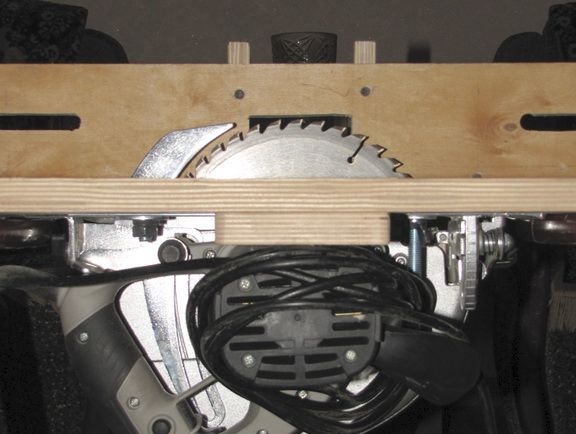

And as it was said above, the author made his circular saw from a manual circular saw, and no changes were made to the design of the saw. A table is simply made here, and the sole of the saw is attached on the underside of the countertop, where it was previously cut under the disk, holes are first drilled and then sawn. A foundation is created from plywood and timber 40x40.

Then, a countertop is cut out of plywood, the author recommends using laminated or varnished, because the surface is even and smooth. As agreed, a cut was made, holes were drilled in the corners for subsequent fastening.

A circular saw is attached to the underside of the countertop, with the help of m-8 bolts, mainly the bolt caps should be drowned in plywood.

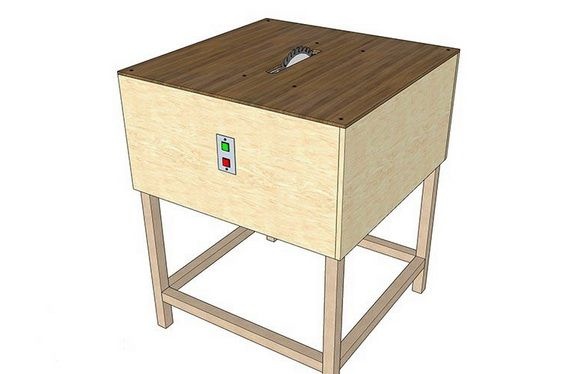

A switch is installed and connected, the start button on the saw is fixed in the pressed position, and the switch is connected to the outlet, so the saw does not need to be disassembled and something needs to be connected to it.

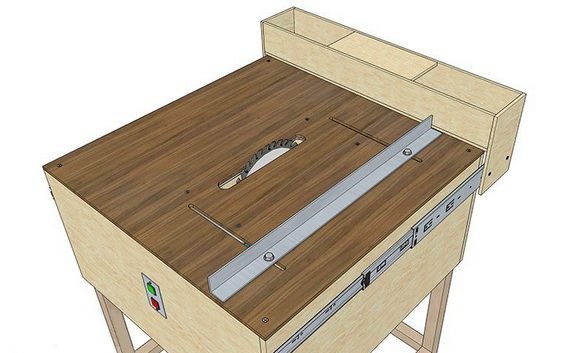

Also, for the convenience of work, a mobile emphasis was placed on furniture rails.

The longitudinal emphasis is made of an aluminum corner.

To adjust it, loosen the bolts and move to the distance necessary for subsequent work.

But as you know, with such a saw installation, 10-20 mm will be lost.

And actually such a saw was obtained by the author.

Also presented to your attention is the video material from which you still learn a lot. Happy viewing!

This concludes the story. Thanks for attention! Come visit more often, do not miss the latest in the world homemade!