To take up such "creativity" was prompted by the statement about the "hard" work of other people's scribes. homemade. We will call this the "pen test."

In order to complicate the task for himself, he completed it with a video plot.

I must say right away, may the author forgive me and let him search for his creation on the Internet. I present YOUR own “creation” to your “court”.

Each motorist, with the purchase of a car acquires a jack for maintenance. Jacks are different, both purely mechanical and purely hydraulic. But they all have a major drawback, it is the convenience of use. It is impossible to install a jack under the car without bending into the "three-dooms". There are more advanced ones for stationary use, but the cost of such "rolls over". That's about such a jack and will be discussed.

The author of the homemade product combined the two types of jacks together. Here's how he did it.

Design Features.

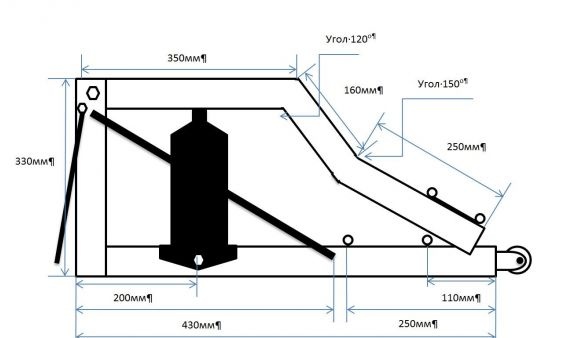

For his design, the author used a ready-made hydraulic jack, making him device . The whole structure consists of a thick-walled channel for 80. made of a whole workpiece. Bends of the structure were achieved by cutting the side walls and further boiling. From the photo you can clearly see the device support rollers (wheels), to dwell on them I do not see the point. For direct support on the car body, a rubber support is fixed, it can be taken from the support pillows of the springs, the engine ... having finished to the desired size.

To install and fix the jack, a metal plate is welded (screwed) to the lower channel, having a jack base size and a thickness of about 5 mm. The main emphasis will be on the channel.

To fix the jack, two holes of 8-10 mm were drilled at its base, and two guide pins were installed at the base of the welded platinum under the jack. That allows you to securely fasten the jack and at the same time freely remove it.

A piston pin was welded to the main rod of the jack from the car, cutting it to the size of the inner width of the channel. This finger rests on the movable part of the device and so that the jack cannot “slip”, limiters in the form of two metal plates with a thickness of at least 8-10 mm are welded on both sides of the finger inside the channel. In this case, the finger should easily rotate there.

For rigidity, welders are welded. In order not to increase the weight of the device, they are not made of solid metal. A handle is also welded for ease of use.

Having rolled up the device under the car, you, as usual, with the help of the handle, start lifting the main rod of the jack and thereby set the lifting lever in motion.

Due to the increased lifting lever, it is possible to completely raise the entire raised side. Both wheels are not supported.

That's probably all about the features of the manufacture of this design.

To give homemade "look", it must be painted.

What do you need to make such a "rolling" jack:

0. The head.

1. Ready hydraulic jack.

2. Channel thick-walled at 80, in the region of 1.5m.

3. Metal plates with a thickness of 5 to 10 mm, 150-200 cm square.

4. Metal "round" with a diameter of 12-16 mm. 1-1.5 meters.

5. The piston pin of the car.

6. Rubber "pillow".

Tool

1. "Bulgarian"

2. Welding.

3. Hand tools.

And if you have a 0-point, you will do it by looking at the photo.

Questions can be directed to the Co-author.