According to the author, one can apply fantasy in this matter, but not depart from building codes and laws!

The barbecue oven presented in the material is quite simple and a person who has no idea about the brickwork can completely cope with its masonry.

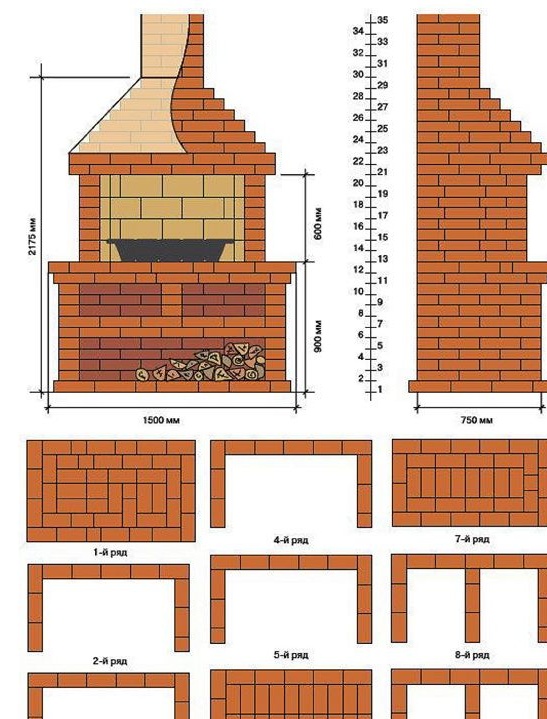

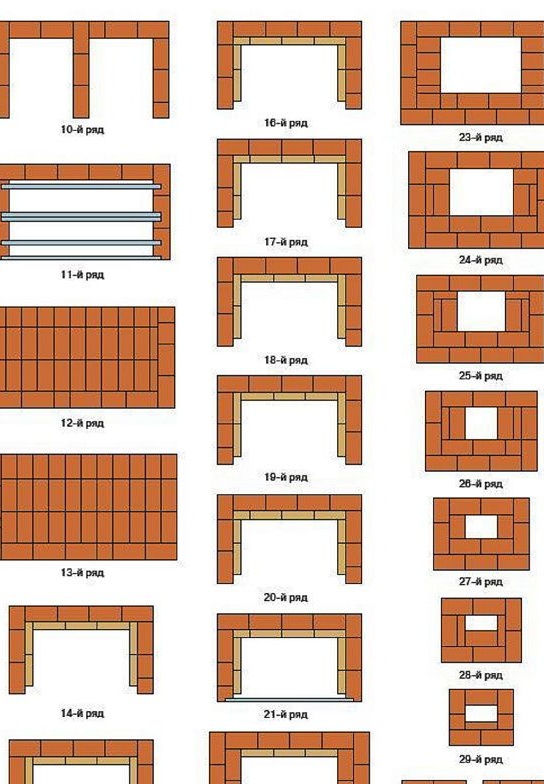

Having studied the schemes and photographs, everything will become clear, the video from the author is also attached to the article, where he will describe each stage in detail and in detail.

Well, let's get down to the analysis of the information provided.

Materials

1. brick (red ceramic)

2. brick (fireclay) slab

3. sand

4. cement

5. red clay

6. fittings

7. steel wire

8. sheet metal 0.7 mm

9. metal plate 2 mm

10. 30 mm board

11. gravel

Instruments

1. shovel

2. concrete mixer

3. hammer

4. trowel

5. level

6. roulette

7. putty knife

8. hacksaw

9. scissors for metal

10. Bulgarian

The process of building a do-it-yourself red brick barbecue stove.

And so, before starting construction it is necessary to determine the location of the future furnace, on your site.

ATTENTION! The furnace should be located at a distance from the capital buildings, in order to avoid fire, because sparks can be carried by the wind, it is also necessary to install a metal spark plug. (Follow fire safety rules!)

After a suitable place is found, it must be cleaned from growing grass, stones, shrubs. If you chose a clean place then "this is wonderful!" and you can start construction, but at the beginning, study the drawings and diagrams presented by the author and determine the type and shape of the future furnace. As the author says, “you can dream up a bit here”

ATTENTION! For laying the furnace, you should use exclusively clay mortar and in no case do not use a cement mixture, because harmful emissions during heating of the cement will evaporate and settle on your food, which can lead to disastrous consequences for your health. So be careful!Inside, the stove is laid out with fireclay refractory bricks, in this case the author used stoves, which is much more convenient, simpler and faster to install.Also, the master falls asleep broken glass in the gap between the stove and the brickwork, the author does not give a description for this action ?! "Probably the secret ingredient" If anyone knows the answer? Write in the comments.Continues to spread the oven inside.That's actually what turns out in the end.Next, the pipe is laid down tapering to the top and a spark arrester cap is installed. made of sheet metal 0.7 mm on metal racks 2 mm thick.Inside, a special grill is placed on the legs for a barbecue, by the way, you can calmly grind this yourself yourself "but that's another story."That's the whole construction process, as you see, there is nothing complicated, and if you wish, any person who knows how to hold the tool in his hands will cope. Now, every weekend, the author will cook meat on coals and delight his relatives and friends.

You can also watch the video footage. teaching masonry stoves.

This concludes the article. Thanks for attention! Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!